Tire pressure sensor and valve assembly

A sensor and air nozzle technology, which is used in tire measurement, tire inflation valve, tire parts, etc., can solve the problem that the fixing bolt is not easy to perform, and achieve the effect of easy locking operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

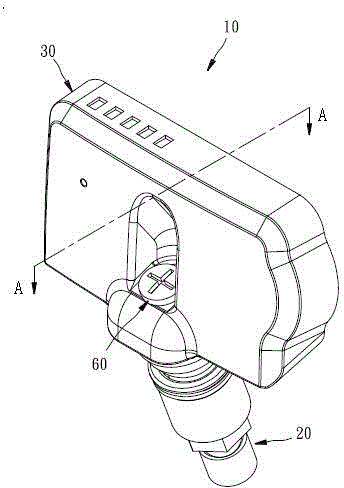

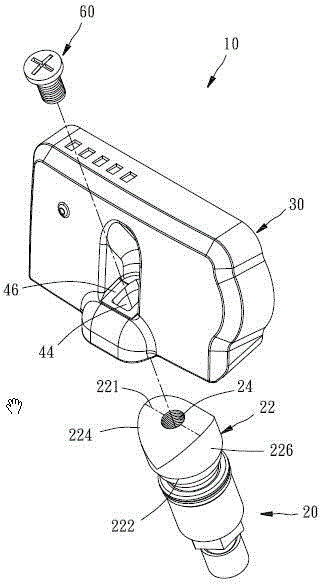

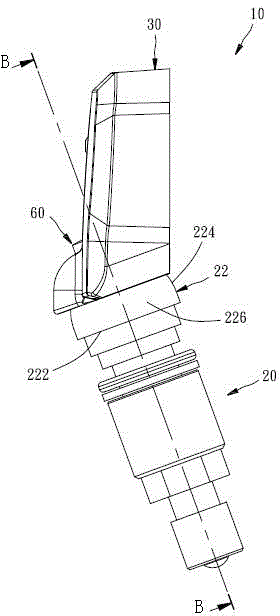

[0038] Such as Figure 1 to Figure 3 As shown, a tire pressure sensor and air nozzle assembly 10 proposed in a preferred embodiment of the present invention includes an air nozzle 20 , a tire pressure sensor 30 , and a bolt 60 .

[0039] The air nozzle 20 has a connecting portion 22 , the connecting portion 22 has a top end 221 and a bottom end 222 opposite to each other, an arc-shaped outer adjustment surface 224 , and an arc-shaped outer abutting surface 226 . The top 221 is in a straight line (as figure 2 and Figure 4 shown). The outer adjusting surface 224 extends from the top end 221 in two opposite directions and toward the bottom end 222 . The outer abutting surface 226 is perpendicular to the top end 221 and extends from the periphery of the outer adjusting surface 224 to the bottom end 222 .

[0040] Another embodiment of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com