Novel elevator falling prevention device

An elevator and anti-fall technology, applied in the directions of transportation, packaging, elevators, etc., can solve problems such as unfavorable large-scale production and generalization, and achieve the effect of saving man-hours and costs, avoiding malfunction, and having a simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

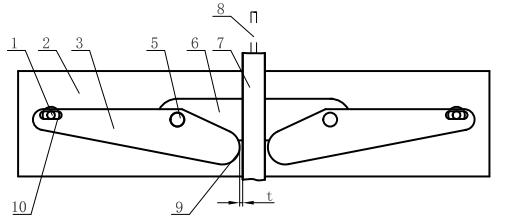

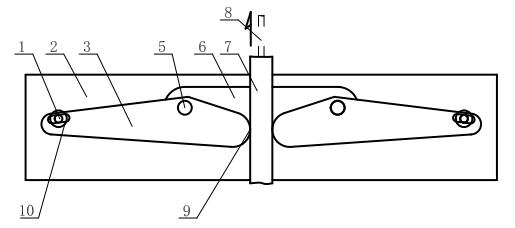

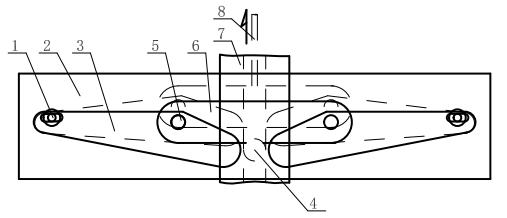

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0037] Such as Figure 1 to Figure 4 As shown, the right-angle bracket 2 of the present invention is installed on the bottom of the car through the top side, and two brake arms 3 and a connecting rod 6 are installed on the side of the right-angle bracket 2, and the two brake arms 3 are placed symmetrically on both sides of the T-shaped guide rail 7. side; the outer end of the brake arm 3 is provided with an oblong hole 10, and the oblong hole is movably pivoted with the fixed pin shaft 1 arranged on the right-angle bracket 2; the inner end of the brake arm 3 is a friction end 9, which is connected with the T-shaped There is a certain gap t on both sides of the guide rail 7, the middle part of the brake arm 3 is pivotally connected to the connecting rod 6 through the transmission pin shaft 5; The arm 3 is provided with a shallow concave ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com