Split prevention method of stitches and split preventor of the same

A stitch and fraying technology, applied in the field of fraying prevention devices, can solve problems such as insufficient fastening, and achieve the effects of preventing fraying, simple structure, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

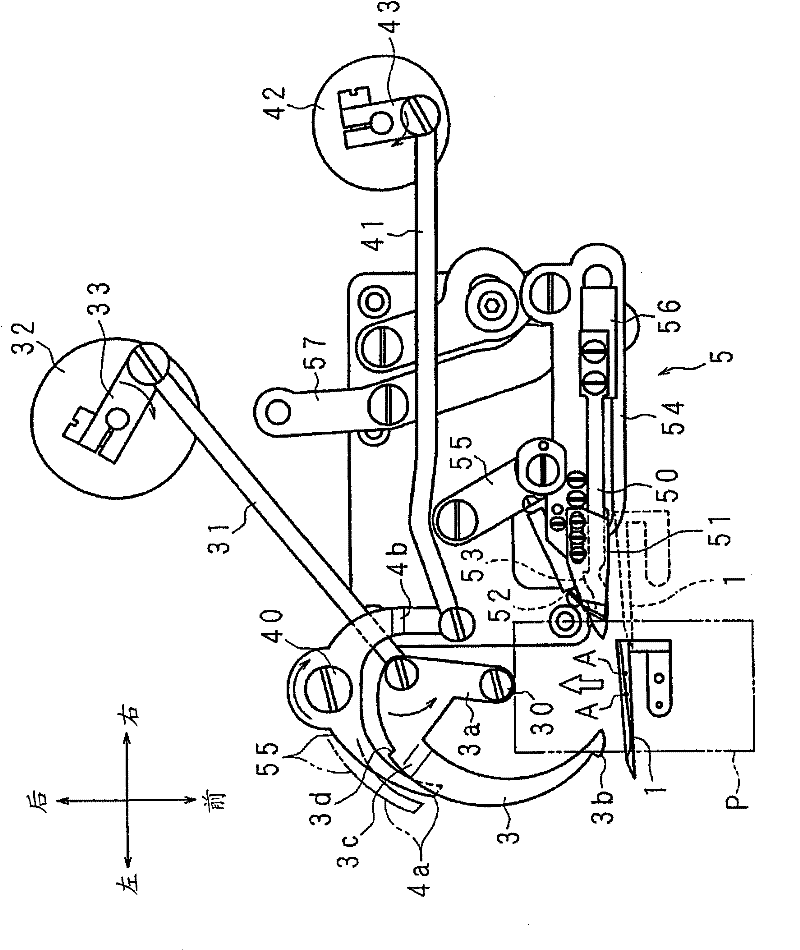

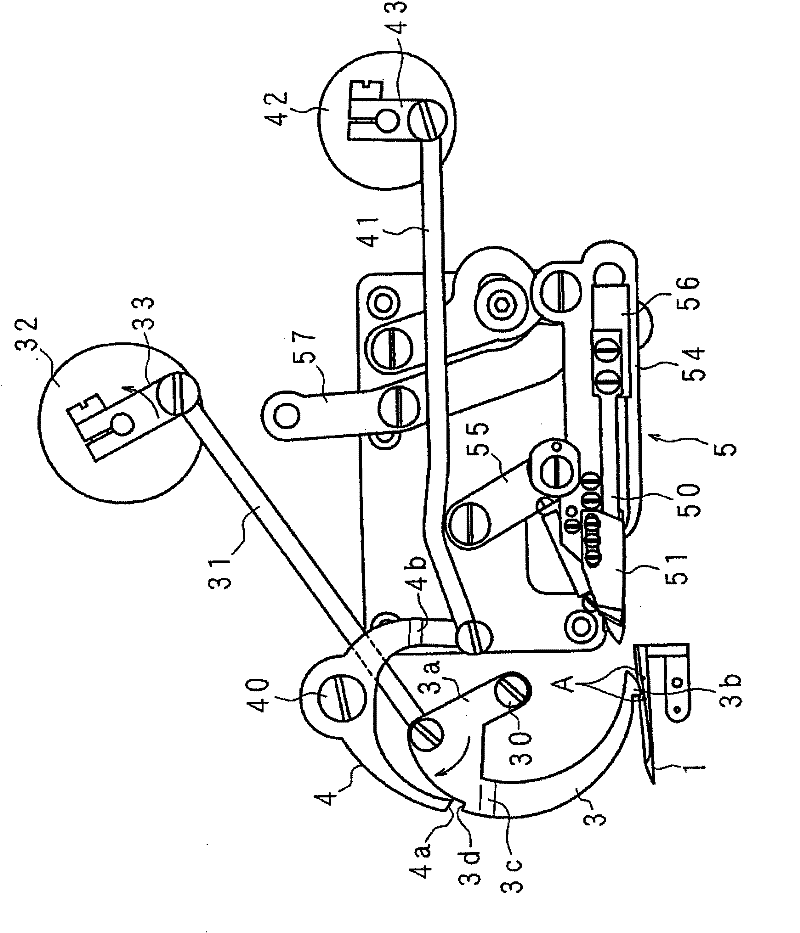

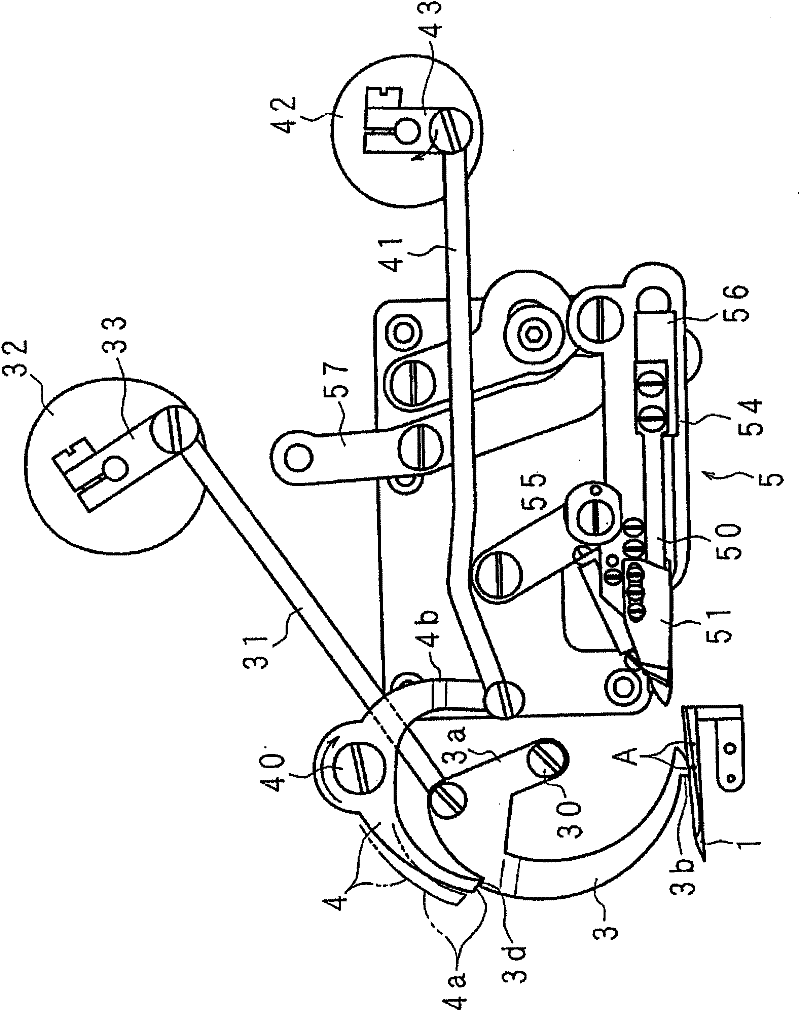

[0090] The stitch fraying prevention device of Embodiment 2 includes a thread hanging hook 3 and a limit lever 4 , and also includes a swing lever 9 . Such as Figure 15 As shown, the thread hook 3 is supported so as to be able to swing around a support shaft 34 in the vertical direction on the upper surface of the needle plate base 10 on which the needle plate P is attached. The support shaft 34 is located in the vicinity of the needle plate P on the right rear side of the needle plate P. As shown in FIG.

[0091] The line hook 3 has an arcuate curved shape, and is connected to the front end portion of a support arm 3 e extending leftward from a support shaft 34 so as to be folded forward. On the lower side of the needle plate P, the front end of the thread hook 3 is adjacent to the needle dropping positions A, A from the rear left side, and an outwardly protruding hook portion 3b is provided at the front end. The support arm 3e also extends forward from the support shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com