Bracket and method for fixing wire rod in bracket

A fixation method and wire technology, applied in stents, medical science, prosthesis, etc., can solve problems such as shape deformation, no research, insufficient expansion force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

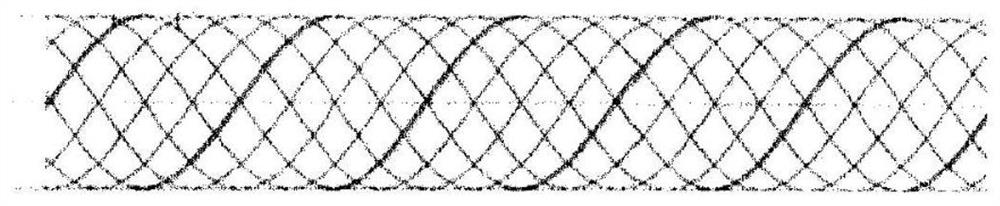

[0025] figure 1 is a schematic diagram showing the shape of a stent. In this embodiment, if figure 1 As shown, it is assumed that multiple wires are woven into a helical scaffold. For the element wire, metal materials such as stainless steel, Co—Cr alloy (cobalt chromium alloy), and Ni—Ti alloy (nickel titanium alloy) are used.

[0026] The stent is formed by weaving a plurality of metal wires in a spiral shape in this way, and there are various types of wires constituting the stent. For example, there are stents with a 16-wire structure in which 16 wires are braided, a stent with a 24-wire structure in which 24 wires are braided, a stent with a 32-wire structure in which 32 wires are braided, and the like. In addition, in figure 1 A scaffold of 16 structures is shown in .

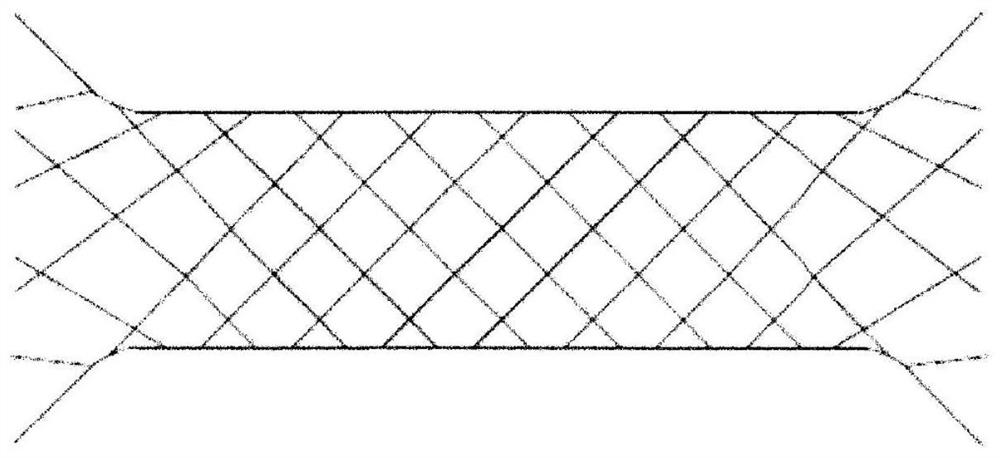

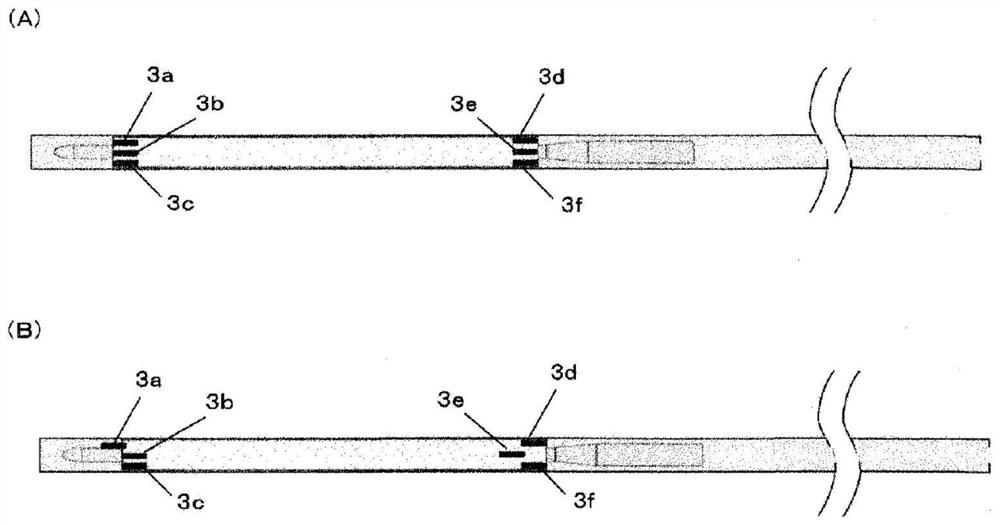

[0027] In such a stent formed by braiding a plurality of metal wires in a helical shape, usually the two ends of the wires are not fixed and independent, so as figure 2 As shown, fraying at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com