Cleanable wind guide box cooler

A technology of cooler and air guide box, applied in the direction of machine/engine, rotary piston type/swing piston type pump parts, parts of pumping device for elastic fluid, etc. life, reducing the working efficiency of the cooler, inconvenient cleaning of the cooler, etc., to achieve the effects of low manufacturing cost, improved work efficiency, and convenient maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

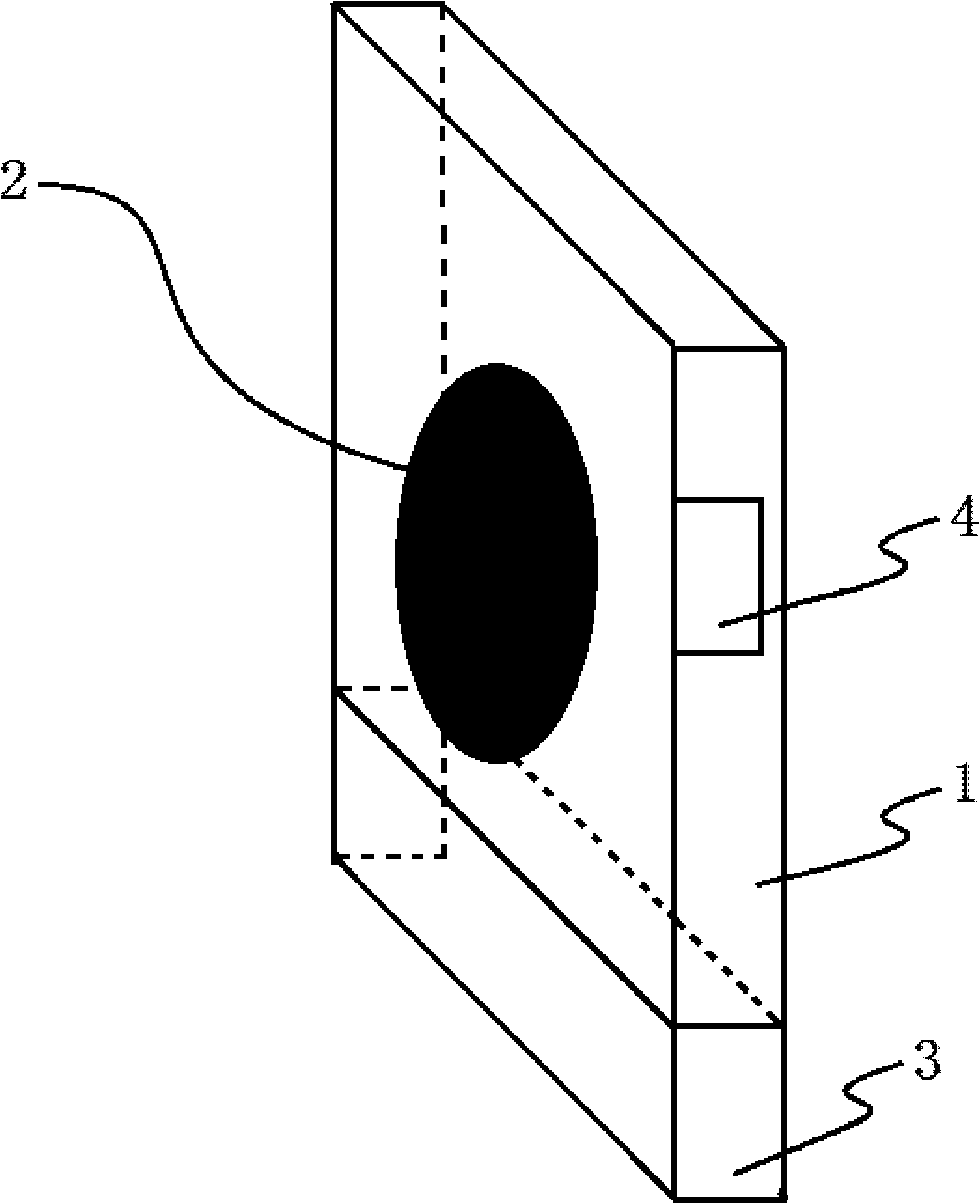

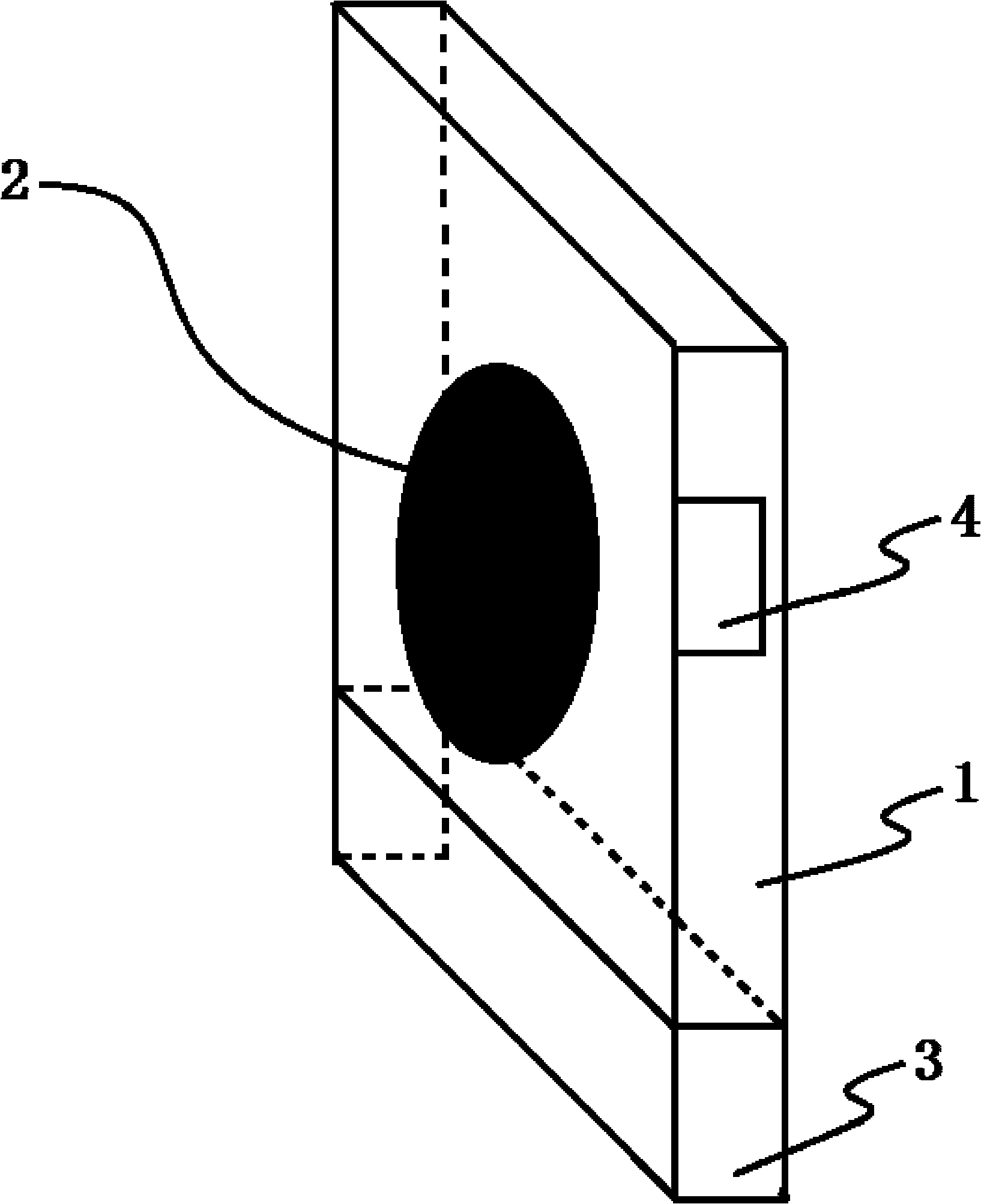

[0016] like figure 1 As shown, it includes cooler, air guide box 1, cooling fan 2, bottom bracket 3, the cooler is built inside the air guide box 1, the air guide box 1 is located on the bottom bracket 3, the air guide box 1 is welded on the bottom bracket 3, and the cooling fan 2 is located outside the air guide box 1, the cooling fan 2 is fixed together with the air guide box 1 by bolts, a window 4 is respectively opened on the side walls of the air guide box 1, and the window 4 is closed with a small plate. The connection between the window 4 and the small board can be snap-fit, or the connection between the window 4 and the small board can be hinged.

[0017] In the present invention, when the cooler needs to be cleaned, the small plates on the side walls on both sides of the air guide box can be removed, so that the inside of the cooler can be easily cleaned. When cleaning, under the action of the cooling fan 2, the air guide box 1 The hole on the outer wall, the air is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com