Cleaning module suitable for projection device

A projection device and cleaning technology, which are applied in the directions of cleaning methods, projection devices, cleaning methods and utensils using gas flow, can solve problems such as increased airflow, increased noise, heat dissipation effects, etc., to avoid dust pollution, prolong service life, The effect of optimal cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention can have various changes in different aspects, all of which do not depart from the scope of the present invention, and the description and illustrations therein are used as illustrations in nature, not to limit the present invention .

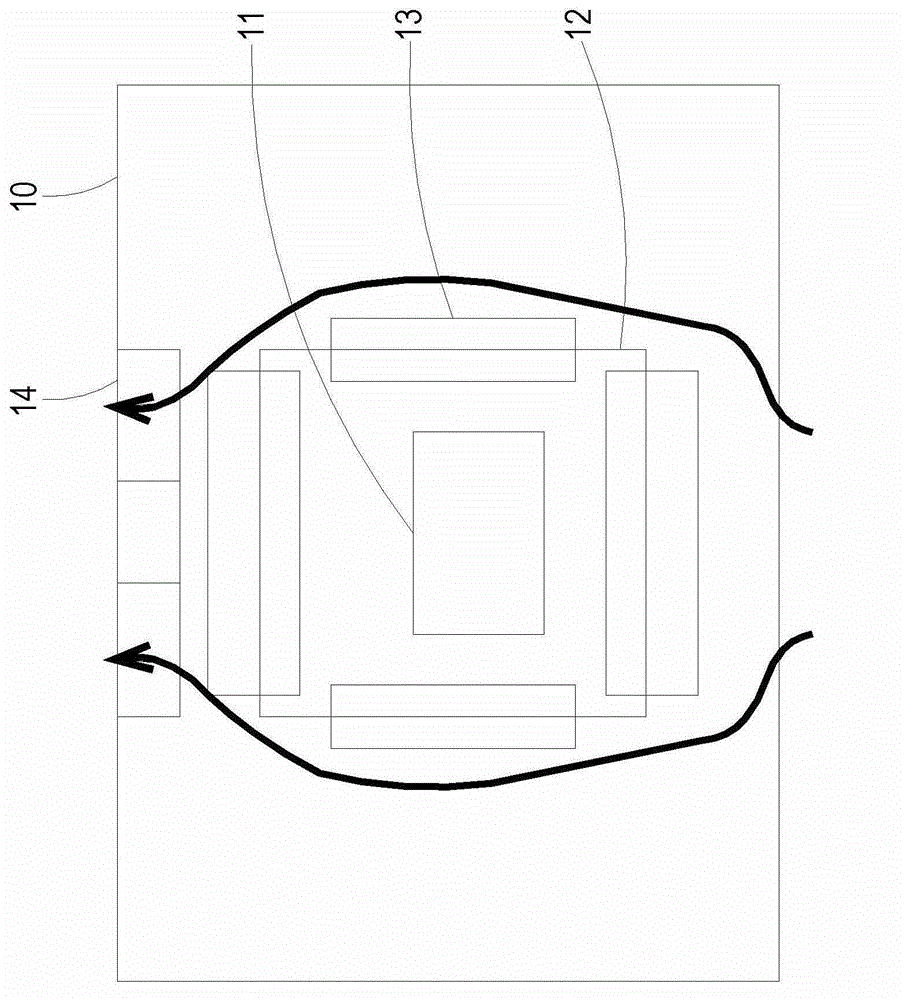

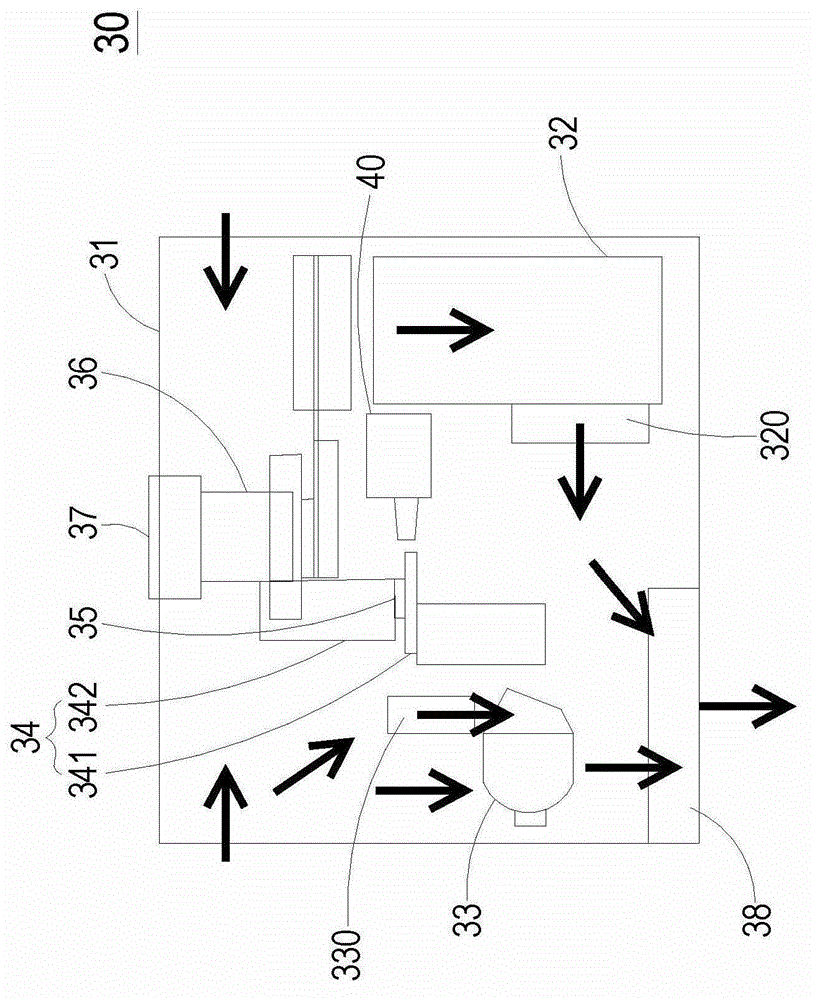

[0049] see image 3 , which is a schematic diagram of the structure of a projection device in a preferred embodiment of the present invention, wherein the projection device of the present invention takes a digital light processing projection device (DLP) as an example. Such as image 3 As shown, the projection device 30 includes at least a casing 31 and a power supply and lighting module 32, a light source module 33, an optical element 34, a sensing element 35, a light engine 36, and a projection lens disposed in the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com