Working medium pollution sampling and analyzing device for small-sized mechanical refrigeration machine

A technology of micro-machines and analysis devices, which is applied in the direction of sampling devices, measuring devices, and analysis materials, etc. It can solve the problems that the non-destructive analysis of gas working fluid in refrigerators cannot be realized, and achieves simple operation, small gas intake volume, and low gas release rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings.

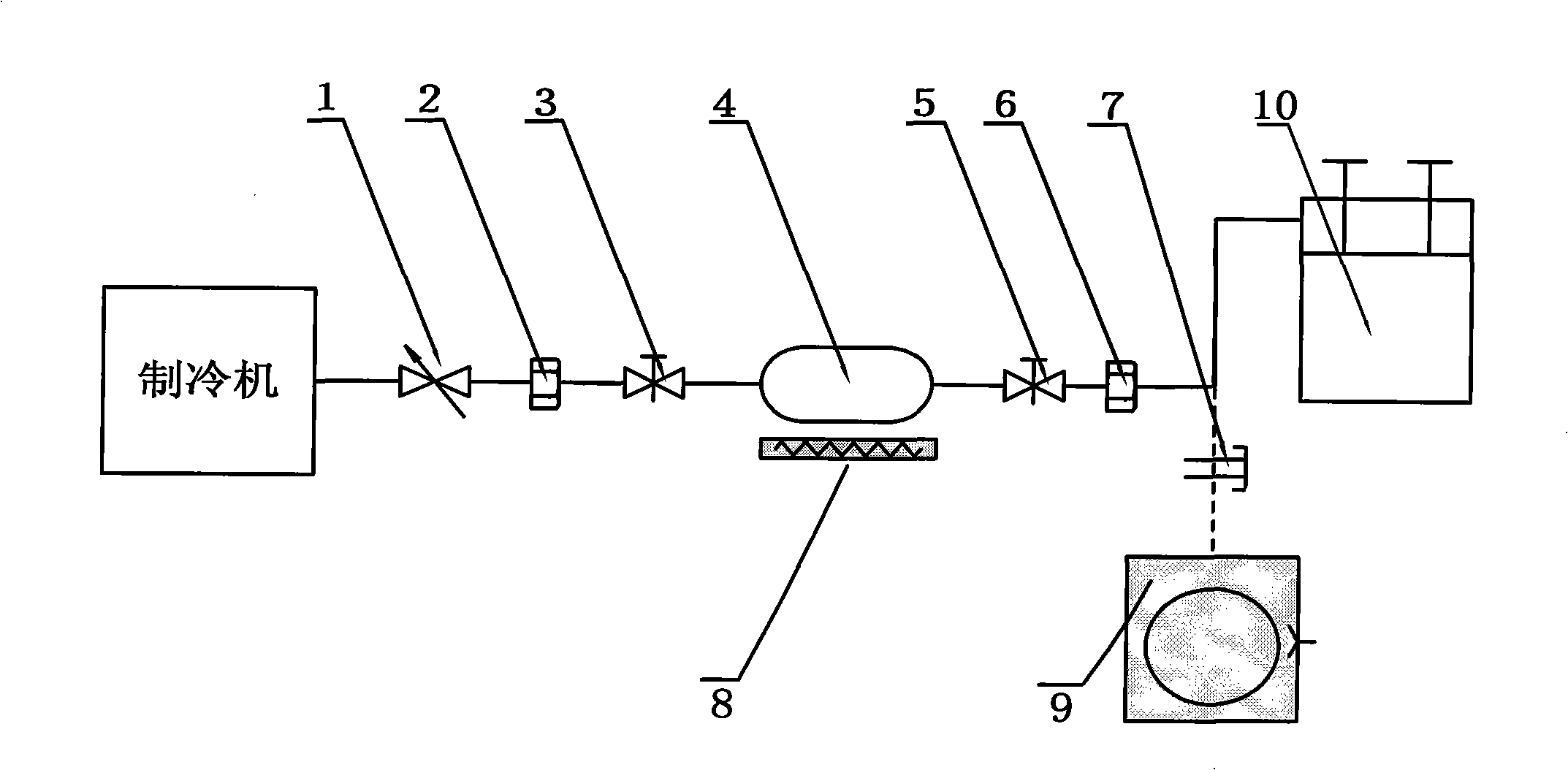

[0019] Such as figure 1 As shown, the sampling and analysis device for working fluid pollution of a micro-mechanical refrigerator includes a two-way gas sampling valve 1 connected to the gas charging valve seat of the refrigerator, an interface 2 connecting the gas sampling valve and the gas storage cylinder, and a control gas sampling valve and the miniature stainless steel bellows valve 3 of the gas storage cylinder, the gas storage cylinder 4, the miniature stainless steel bellows valve 5, the mass spectrometer interface 6, the vacuum pump interface 7, the heating table (8), the vacuum pump 9 and the mass spectrometer 10.

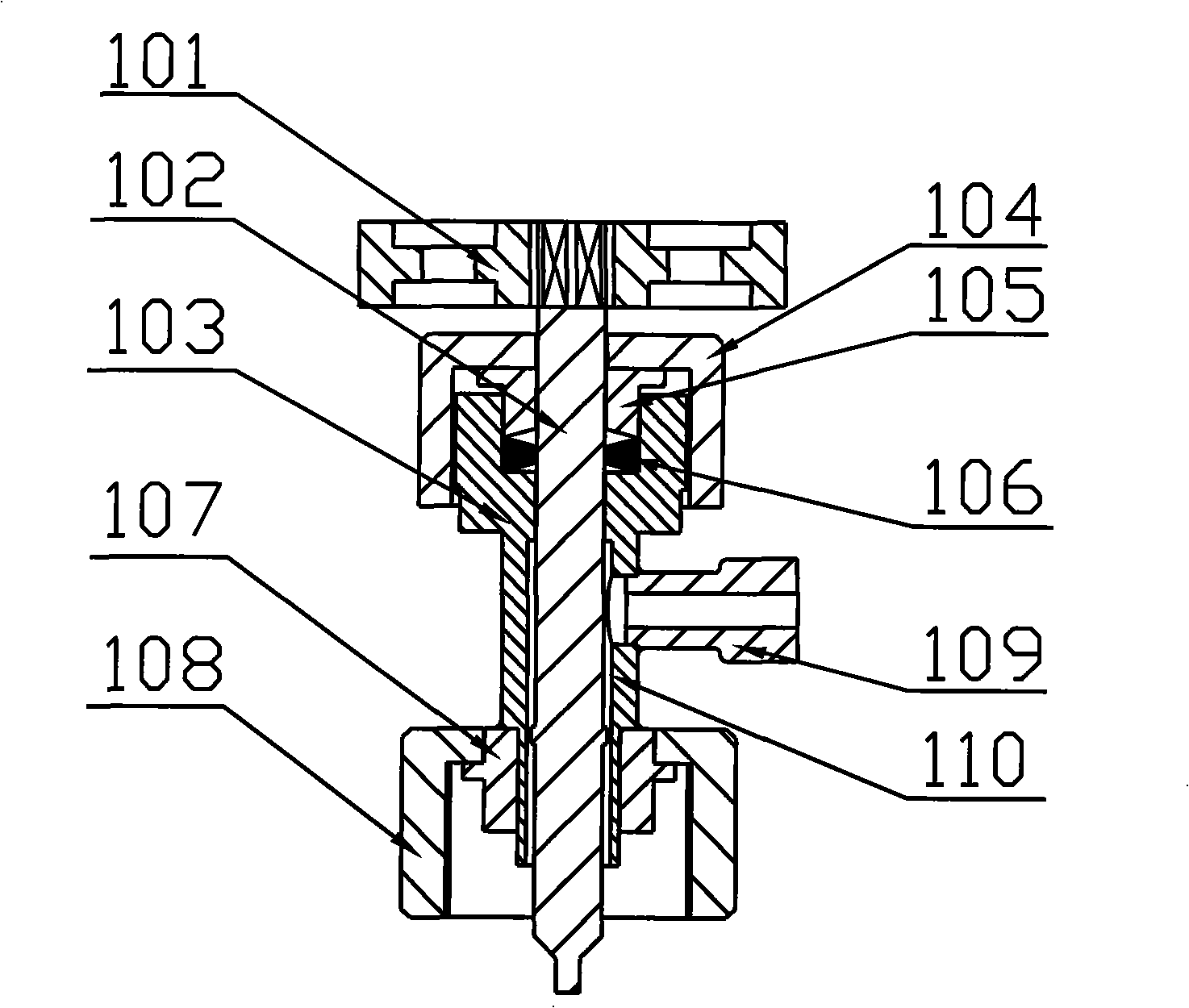

[0020] The air intake valve 1 of the present invention is made of stainless steel material with a low deflation rate, and the difference from the usual two-way high vacuum valve is that the inner cavity is less than 1cc, so that the performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com