Method for dyeing wool fibres by using acidic mordant dye

A wool fiber and mordant dye technology, which is applied in the dyeing of acid mordant dyes. The use of acid mordant dyes to dye wool fibers can solve the problems of high concentration of free chromium ions, high concentration of heavy metal chromium ions, and harm to human health. Achieve the effects of reducing the content of free chromium ions, reducing damage to the environment, and avoiding damage to health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

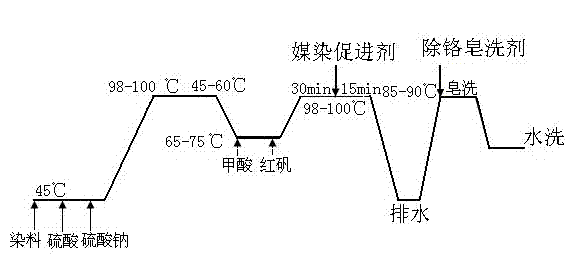

[0030] 80 kg light black (gray) color wool dyeing process:

[0031] Put the wool fiber into a cage and put it into the dyeing vat, add 800 kg of water to the dyeing vat, turn on the circulating heating pump of the dyeing vat and raise the temperature to 45°C, add 0.8 kg of dye acid medium black PV to the dyeing vat (add after dissolving in hot water and filtering), add 0.4 kg of sulfuric acid (cold water Add after dilution), add 3.2 kg of sodium sulfate (add after dissolving in cold water), keep warm at 45°C for 15 minutes, heat up at 1°C / min, heat up to 98-100°C for 45 minutes, cool down to 70°C and add 0.8 kg of formic acid ( Add after diluting with water), add 0.28 kg of red alum (add after dissolving in water), keep warm for 10 minutes, raise the temperature to 98-100°C, keep warm for 30 minutes, add 0.4 kg of mordant accelerator (add after diluting with water), keep warm for 15 minutes, Drain and rinse, add water and heat up to 90°C, add 0.8 kg of chromium-removing soapin...

Embodiment 2

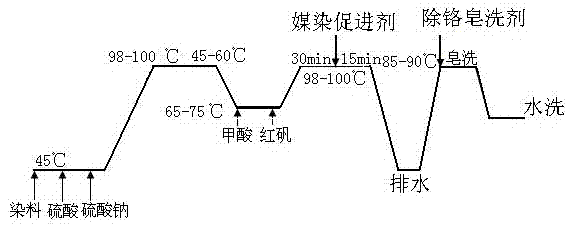

[0033] 80 kg deep black wool dyeing process:

[0034] Put the wool fiber into the cage and put it into the dyeing vat, add 800 kg of water to the dyeing vat, turn on the circulating heating pump of the dyeing vat and raise the temperature to 45°C, add 3.2 kg of dye acid medium black PV to the dyeing vat (add after dissolving in hot water and filtering), add 0.8 kg of sulfuric acid (cold water Add after dilution), add 4.0 kg of sodium sulfate (add after dissolving in cold water), keep warm at 45°C for 15 minutes, heat up at 1°C / min, heat up to 98-100°C for 45 minutes, cool down to 70°C and add 0.8 kg of formic acid ( Add after diluting with water), add 0.64 kg of red alum (add after dissolving in water), keep warm for 10 minutes, raise the temperature to 98-100°C, keep warm for 30 minutes, add 1.6 kg of mordant accelerator (add after diluting with water), keep warm for 15 minutes, Drain and rinse, add water and heat up to 90°C, add 1.6 kg of chromium-removing soaping agent, kee...

Embodiment 3

[0036] 80 kg bright blue wool dyeing process:

[0037] Put the wool fiber into the cage and put it into the dyeing vat, add 800 kg of water to the dyeing vat, turn on the circulating heating pump of the dyeing vat and raise the temperature to 45°C, add 1.6 kg of dye acid medium Biaolan B to the dyeing vat (add after dissolving and filtering in hot water), add 0.8 kg of sulfuric acid ( Add after diluting with cold water), add 2.4 kg of sodium sulfate (add after dissolving in cold water), keep warm at 45°C for 15 minutes, heat up at 1°C / min, heat up to 98-100°C for 45 minutes, cool down to 70°C and add 0.6 kg of formic acid (add after diluting with water), add 0.4 kg of red alum (add after dissolving in water), keep warm for 10 minutes, raise the temperature to 98-100°C, keep warm for 30 minutes, add 0.8 kg of mordant accelerator (add after diluting with water), keep warm for 15 minutes , drain and rinse, add water and heat up to 90°C, add 0.8 kg of chromium-removing soaping age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com