Automated analysis device with an automatic pipetting device and a pipetting needle rinsing station

A suction needle, automatic technology, applied in the direction of analysis materials, laboratory equipment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

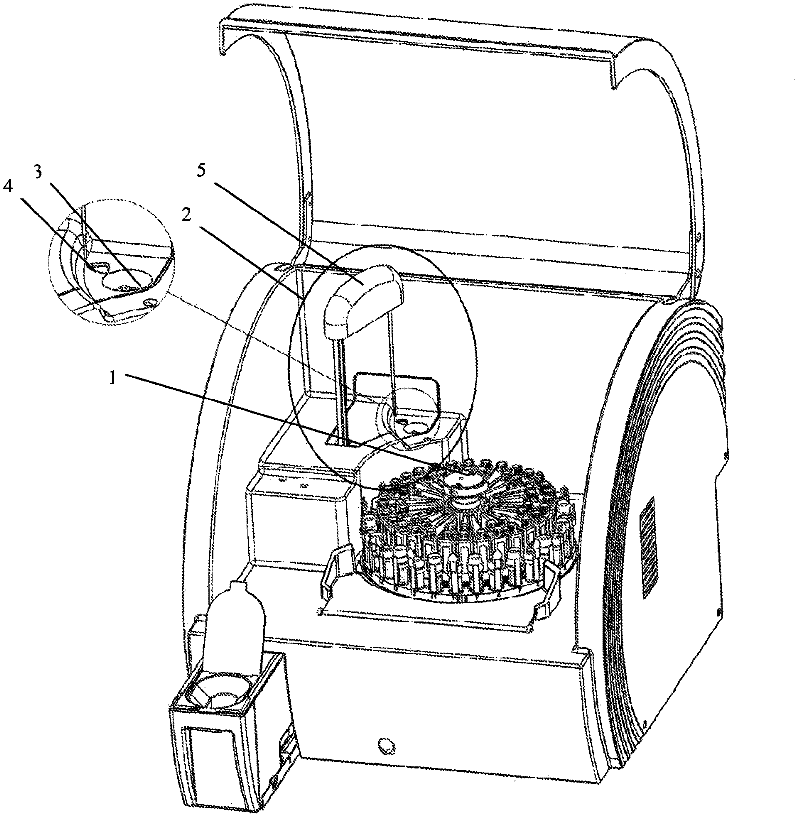

[0060] figure 1 A device for the automatic analysis of liquids (analyzer) is shown, which has a carousel 1 for liquid containers and a pipetting device 2 with a pipetting arm 5 . The carousel 1 is arranged to move liquid containers into the working area of the pipetting arm 5 . Furthermore, a rinsing station 3 and a measuring device 4 for determining the exact position of the tip of the pipetting needle are also arranged in the working area of the pipetting arm 5 .

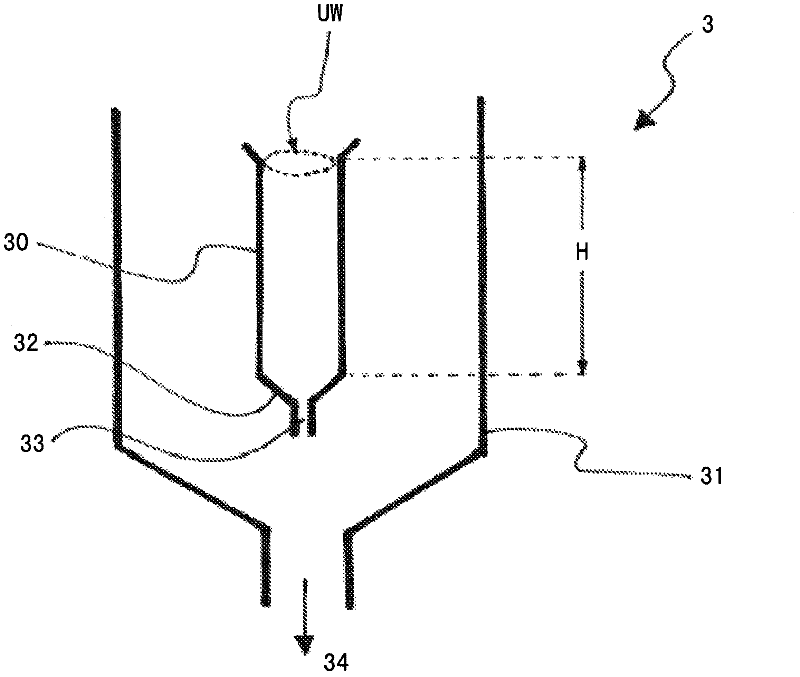

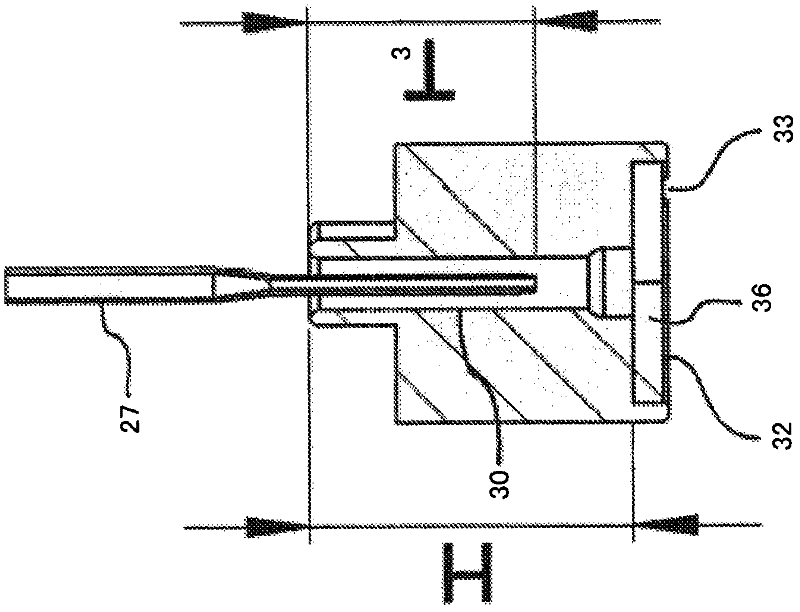

[0061] figure 2 The rinsing station 3 of the present invention is schematically shown in . A hollow cylindrical washing basin with an opening at the top is arranged in a drip tray 31 , and a discharge pipe 34 is arranged in the drip tray 31 , wherein the height of the hollow cylinder is defined as H. The hollow cylinder has an inner circumference UW. At the upper edge of the hollow cylinder, the wash basin 30 is made slightly wider towards the outside. In this embodiment, the bottom of the wash basin 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com