Koji pressing mechanism

A technology of compression molding and hydraulic cylinders, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of low koji medicine, single operation action, and affecting the quality of wine, so as to achieve the effect of improving quality and meeting quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

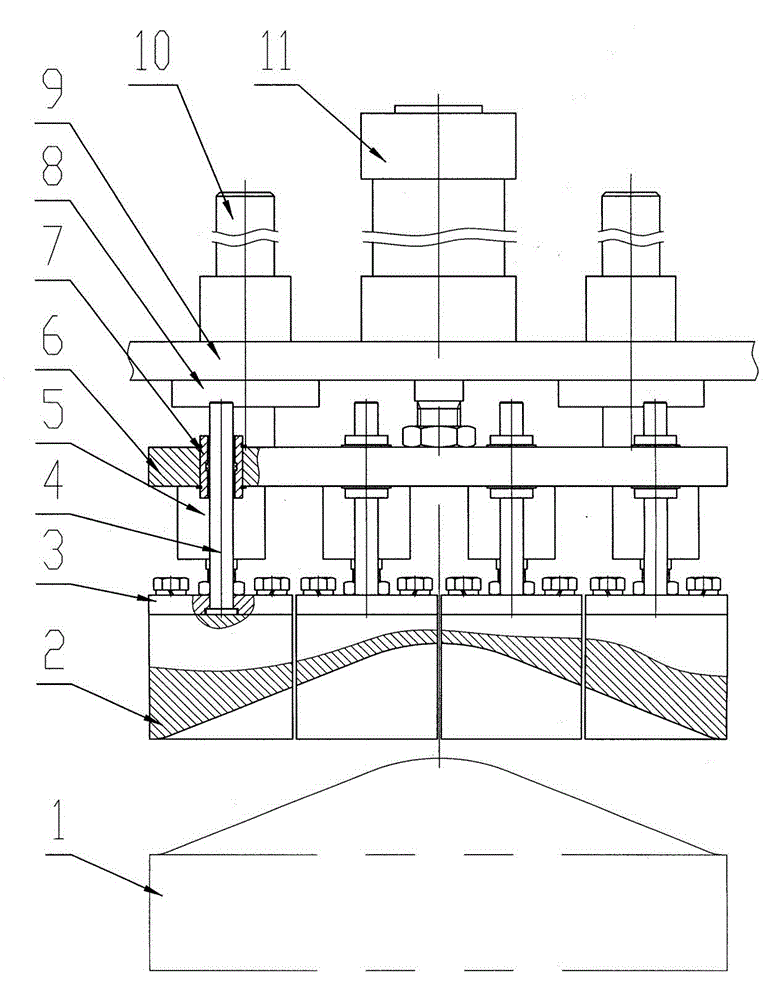

[0008] Embodiment 1: The mold cylinder connection plate 3 is fixed on the die 2, the cylinder guide rod 4 is fixed on the mold cylinder connection plate 3, the cylinder 5 is fixed on the cylinder installation plate 6, the piston rod of the cylinder 5 is connected to the mold cylinder connection plate 3, and the sliding bearing 7 is fixed on the cylinder mounting plate 6, the cylinder guide rod 10 is fixed on the cylinder mounting plate 6, the flange sliding bearing 8 is fixed on the cylinder mounting plate 9, the hydraulic cylinder 11 is fixed on the cylinder mounting plate 9, the piston rod of the hydraulic cylinder 11 is connected to the cylinder for installation board6.

[0009] When buckling, put the preliminarily formed bent medicine block 1 under the die 2, and the hydraulic cylinder 11 drives the die 2, the mold cylinder connecting plate 3, the cylinder guide rod 4, the cylinder 5, the cylinder mounting plate 6, and the sliding bearing 7 as a whole. Move down to stop a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com