One-piece seat structure and cold forming processes to create seat structures

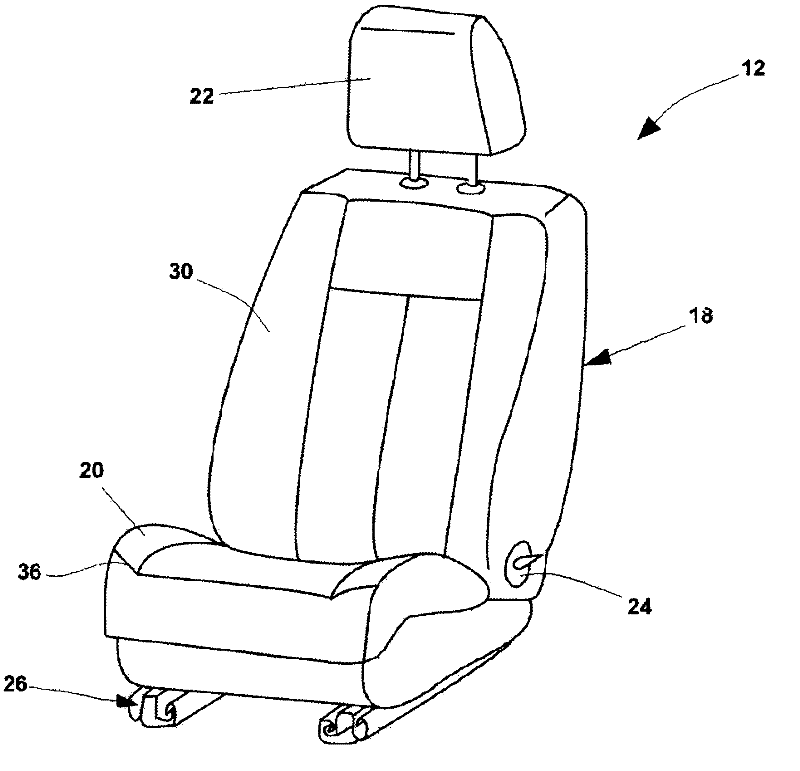

A single seat, cold forming technology, applied in the direction of seat frames, vehicle seats, chairs, etc., can solve the problems of increasing unit cost and manufacturing cycle time, reducing reliability, reducing parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

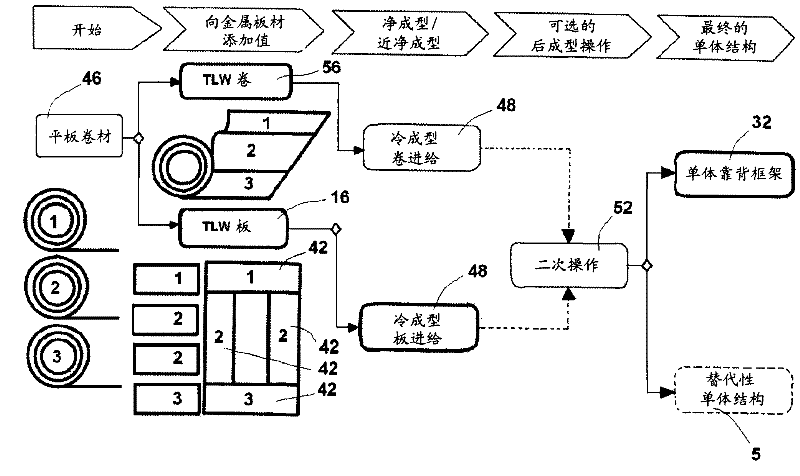

Method used

Image

Examples

Embodiment approach

[0048] refer to Figure 14 , which shows another exemplary embodiment of a conventional seat back structure 117 supporting multiple occupants, which includes: at least one formed tube 116; at least one back panel 118; a plurality of brackets 120 to attach seat belt rolls Retractor assembly 122; super high strength tower (tower) 124, to transfer the load from retractor 122; Multiple mounting brackets 120, to connect to recliner mechanism 24; And, multiple brackets 120, to attach Joint pillow assembly 22. This embodiment offers considerable opportunities for weight and cost savings by integrating multiple components into a single-piece seat back structure 32 or multiple single-piece seat structures 5 to be joined by a secondary operation.

[0049] refer to Figure 15 , which illustrates another exemplary embodiment of a conventional pivotable seat cushion structure 126 supporting multiple passengers, comprising: at least one shaped tube 128; at least one dolly 130; a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com