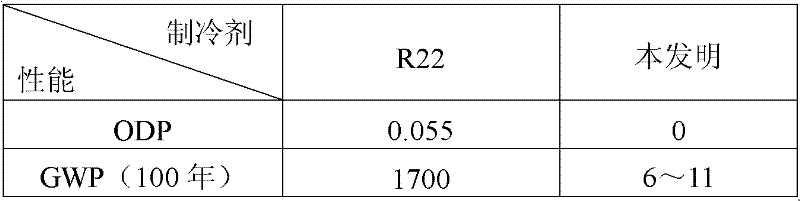

Refrigerant composition with low GWP (Global Warming Potential) value

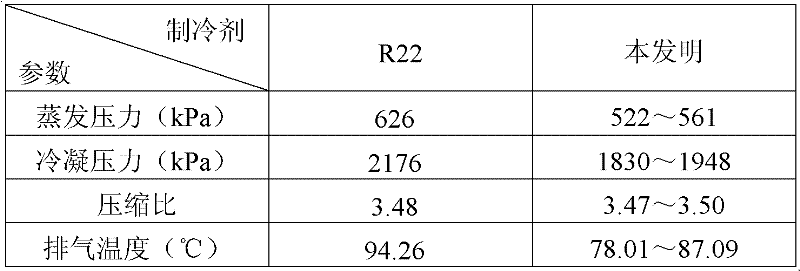

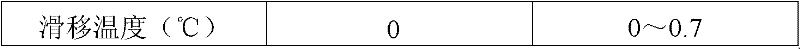

A composition and refrigerant technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high slip temperature, high exhaust temperature, low performance, etc., and achieve the effect of reducing the charging amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: A low-GWP refrigerant composition consisting of 30% fluoroethane and 70% 2,3,3,3-tetrafluoropropene.

[0046] Preparation method: Physically mix fluoroethane and 2,3,3,3-tetrafluoropropene in the liquid phase according to the corresponding mass ratio to obtain the refrigerant.

Embodiment 2

[0047] Example 2: A low-GWP refrigerant composition consisting of 40% fluoroethane and 60% 2,3,3,3-tetrafluoropropene.

[0048] The preparation method is the same as in Example 1.

Embodiment 3

[0049] Example 3: A low-GWP refrigerant composition consisting of 50% fluoroethane and 50% 2,3,3,3-tetrafluoropropene.

[0050] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com