Bar-shaped composite insulator

A composite insulator and rod-shaped technology, applied in the direction of insulators, supporting insulators, suspension/strain insulators, etc., can solve the problems of concentration and accelerated decline in the mechanical strength of composite insulators, and achieve high-strength sealing, best pollution flashover characteristics, and prevent The effect of brittle accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

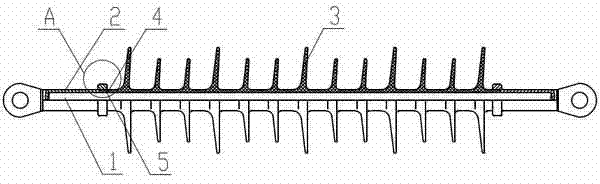

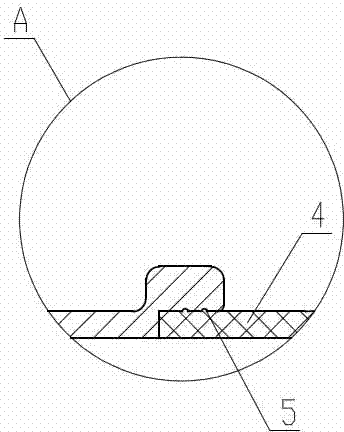

[0023] Such as figure 1 , figure 2 As shown, the rod-shaped composite insulator of the present invention is a suspended rod-shaped composite insulator, including a mandrel 1, metal fittings 2 provided at both ends of the mandrel, and a sheath 4 with an umbrella shed structure 3 covered by the mandrel 1 , two annular grooves 5 are provided on the inner wall of the fitting 2 at the interface between the fitting 2 and the sheath 4; the uptilt angle of the shed structure 3 is 8°, and the downtilt angle is 0°; wherein the shed structure 3 It is a large umbrella with the same diameter arranged coaxially with the mandrel 1 and two small umbrellas with the same diameter between each adjacent large umbrella. The distance between the two adjacent umbrellas is 90mm-120mm. The extension ratio is 1.35 to 1.40, and the extension of the large umbrella is 55mm to 60mm.

Embodiment 2

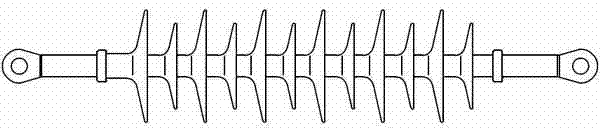

[0025] Such as image 3 As shown, the rod-shaped composite insulator of the present invention is a suspended rod-shaped composite insulator, including a mandrel 1, metal fittings 2 provided at both ends of the mandrel, and a sheath 4 with an umbrella shed structure 3 covered by the mandrel 1 , two annular grooves 5 are provided on the inner wall of the fitting 2 at the interface between the fitting 2 and the sheath 4; the uptilt angle of the shed structure 3 is 8°, and the downtilt angle is 0°; wherein the shed structure 3 It is a large umbrella with the same diameter set coaxially with the mandrel 1 and a small umbrella with the same diameter between each adjacent large umbrella. The distance between the two adjacent umbrellas is 50mm-60mm. The extension of the large umbrella and the extension of the small umbrella The output ratio is 1.60-1.85, and the extension of the large umbrella is 32mm-40mm.

Embodiment 3

[0027] Such as Figure 4 , Figure 5 As shown, the rod-shaped composite insulator of the present invention is a suspended rod-shaped composite insulator, including a mandrel 1, metal fittings 2 provided at both ends of the mandrel, and a sheath 4 with an umbrella shed structure 3 covered by the mandrel 1 , two annular grooves 5 are provided on the inner wall of the fitting 2 at the interface between the fitting 2 and the sheath 4; the uptilt angle of the shed structure 3 is 8°, and the downtilt angle is 0°; wherein the shed structure 3 It is a large umbrella with the same diameter arranged coaxially with the mandrel 1 and two small umbrellas with the same diameter between each adjacent large umbrella. The distance between the two adjacent umbrellas is 80mm-90mm. The extension ratio is 1.40-1.45, and the extension of the large umbrella is 50mm-55mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com