Bar-shaped composite insulator for electronic railway connecting net plane

A composite insulator, rod-shaped technology, applied in the direction of circuits, insulators, electrical components, etc., can solve the problems of concentration and accelerated decline in the mechanical strength of composite insulators, achieve high-strength sealing, best pollution flashover characteristics, and prevent brittle fracture accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

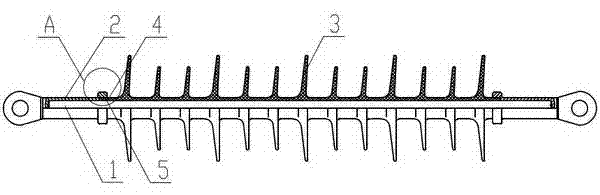

[0023] like figure 1 , figure 2 As shown, the rod-shaped composite insulator for electrified railway catenary according to the present invention is a suspended rod-shaped composite insulator, including a mandrel 1, metal fittings 2 provided at both ends of the mandrel, and an umbrella skirt structure covered by the mandrel 1 The sheath 4 of 3 is provided with two annular grooves 5 on the inner wall of the metal fitting 2 at the interface position of the fitting 2 and the sheath 4; the up inclination angle of the shed structure 3 is 8°, and the down inclination angle is 0°; The umbrella skirt structure 3 is a large umbrella with the same diameter coaxial with the core rod 1 and two small umbrellas with the same diameter between each adjacent large umbrellas. The distance between the two adjacent umbrellas is 90mm to 120mm. The ratio of the extension to the small umbrella is 1.35 to 1.40, and the extension of the large umbrella is 55mm to 60mm.

Embodiment 2

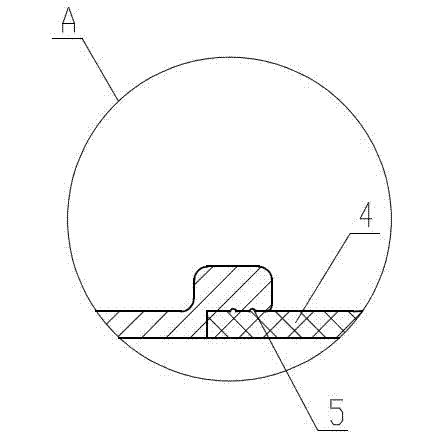

[0025] like image 3 As shown, the rod-shaped composite insulator for electrified railway catenary according to the present invention is a suspended rod-shaped composite insulator, including a mandrel 1, metal fittings 2 provided at both ends of the mandrel, and an umbrella skirt structure covered by the mandrel 1 The sheath 4 of 3 is provided with two annular grooves 5 on the inner wall of the metal fitting 2 at the interface position of the fitting 2 and the sheath 4; the up inclination angle of the shed structure 3 is 8°, and the down inclination angle is 0°; The umbrella skirt structure 3 is a large umbrella with the same diameter coaxial with the core rod 1 and a small umbrella with the same diameter between each adjacent large umbrella, the distance between the two adjacent umbrellas is 50mm to 60mm, and the large umbrella extends out. The ratio of the extension to the small umbrella is 1.60 to 1.85, and the extension of the large umbrella is 32mm to 40mm.

Embodiment 3

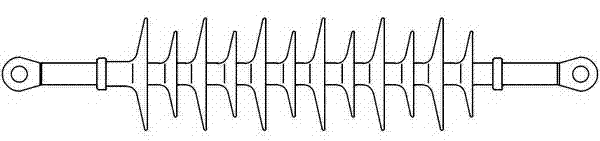

[0027] like Figure 4 , Figure 5 As shown, the rod-shaped composite insulator for electrified railway catenary according to the present invention is a suspended rod-shaped composite insulator, including a mandrel 1, metal fittings 2 provided at both ends of the mandrel, and an umbrella skirt structure covered by the mandrel 1 The sheath 4 of 3 is provided with two annular grooves 5 on the inner wall of the metal fitting 2 at the interface position of the fitting 2 and the sheath 4; the up inclination angle of the shed structure 3 is 8°, and the down inclination angle is 0°; The umbrella skirt structure 3 is a large umbrella with the same diameter coaxial with the core rod 1 and two small umbrellas with the same diameter between each adjacent large umbrella. The distance between the two adjacent umbrellas is 80mm to 90mm. The ratio of the extension to the small umbrella is 1.40 to 1.45, and the extension of the large umbrella is 50mm to 55mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com