Ferroelectric-antiferroelectric (FE-AFE) phase change pyroelectric ceramic material, ceramic element thereof and preparation methods thereof

A technology of pyroelectric ceramics and ceramic materials, which is applied to ferroelectric-antiferroelectric phase change pyroelectric ceramic materials and ceramic components, and the field of phase change pyroelectric ceramics, which can solve the problems of limited practical application and large thermal hysteresis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

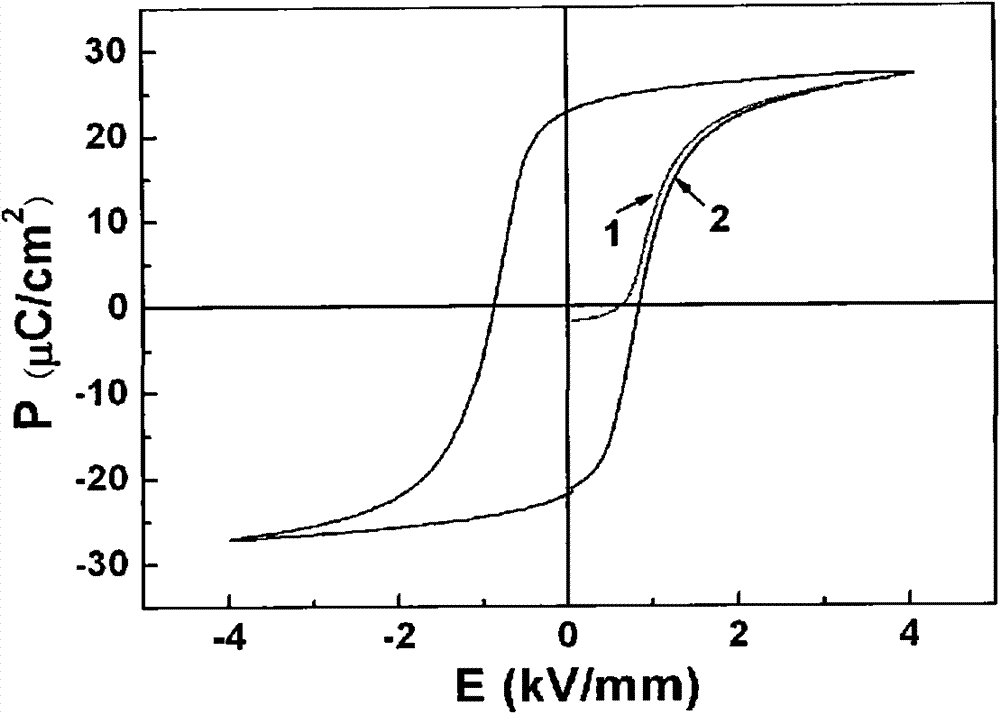

[0051] The chemical formula of ferroelectric-antiferroelectric pyroelectric ceramic material is:

[0052] Pb 0.97 La 0.02 (Zr 0.42 Ti 0.18 sn 0.40 )O 3

[0053] (1) Calculate the composition Pb in the powder raw material according to the composition of the above chemical formula 3 o 4 , ZrO 2 、TiO 2 , SnO 2 and La 2 o 3 The mass and according to the composition ratio preparation, mixed by wet ball milling, according to the mass ratio of raw material: ball: water = 1: 1.6: 0.8 and mixed for 6 hours, so that each component was mixed evenly. After drying, add 10wt.% deionized water of the powder raw material, briquette in the air atmosphere, raise the temperature to 850°C at a rate of less than 2°C / min, and keep it warm for 2 hours to synthesize Pb 0.97 La 0.02 (Zr 0.42 Ti 0.18 sn 0.40 )O 3 of ceramic powder.

[0054] (2) smash the ceramic powder obtained in step (1), pass through a 30-mesh sieve, and finely grind for 24 hours by wet ball milling, dry the ceram...

Embodiment 2

[0066] The chemical formula of ferroelectric-antiferroelectric pyroelectric ceramic material is:

[0067] Pb 0.9625 La 0.025 (Zr 0.42 Ti 0.18 sn 0.40 )O 3

[0068] By repeating the preparation method of Example 1 according to the above chemical formula, a high pyroelectric response can be obtained at a lower temperature.

[0069] The pyroelectric performance after polarization treatment was tested for the ceramic element of this embodiment, and the test results are shown in Table 1.

[0070] The pyroelectric performance and thermal hysteresis of temperature rise and fall were tested for the ceramic element in this embodiment, and the test results are shown in Table 2.

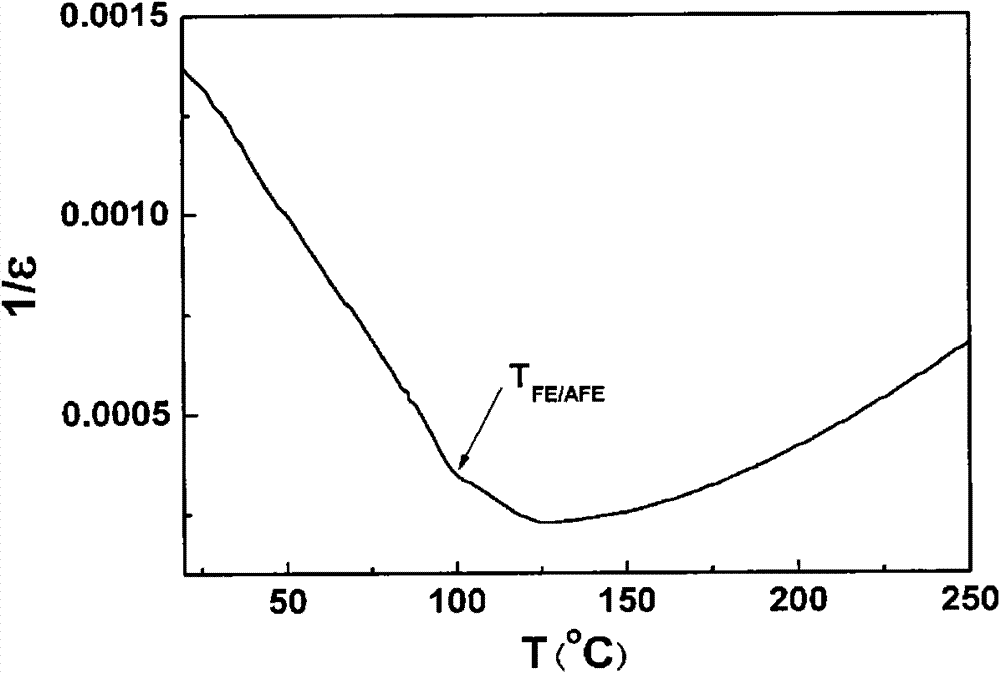

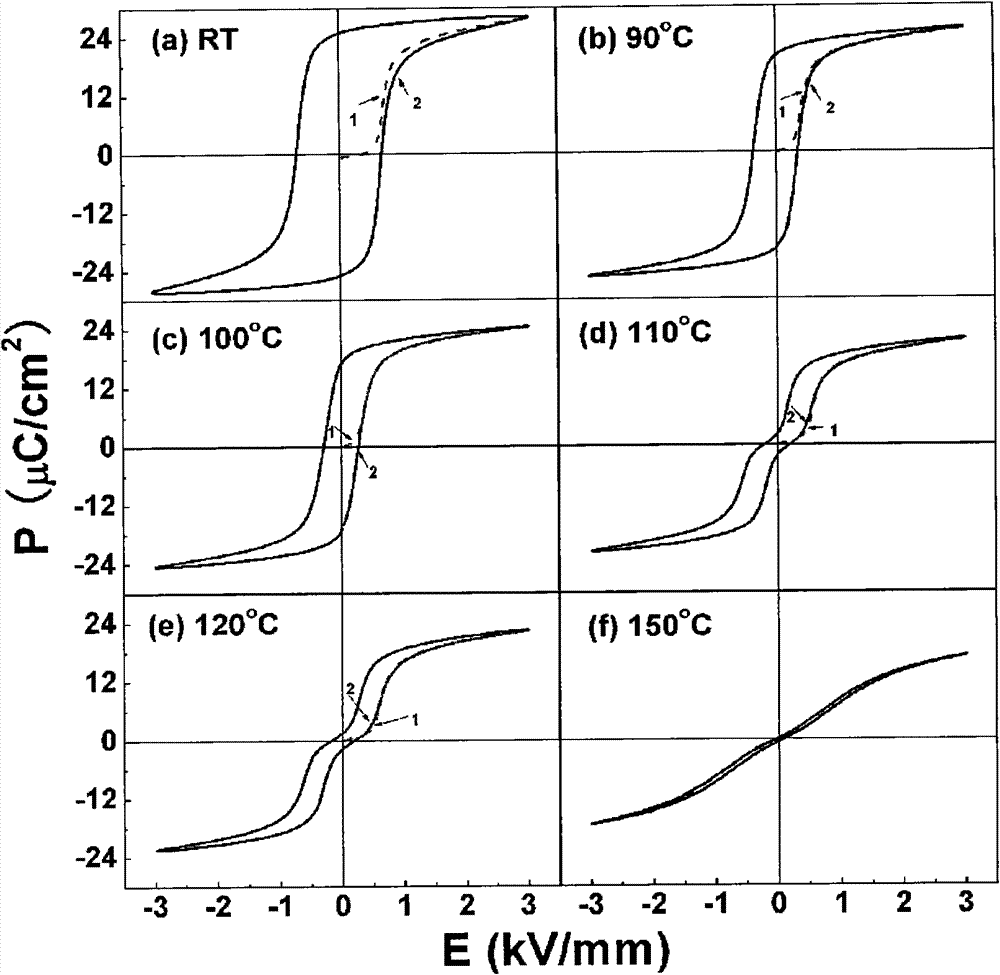

[0071] It has been detected that the obtained ceramic element is in the FE phase at room temperature, and the phase transition of the ceramic element will only occur under temperature induction, and the phase transition that occurs is FE-AFE phase transition.

Embodiment 3

[0073] The chemical formula of ferroelectric-antiferroelectric pyroelectric ceramic material is:

[0074] Pb 0.9775 La 0.015 (Zr 0.42 Ti 0.18 sn 0.40 )O 3

[0075] The preparation method of Example 1 was repeated according to the above chemical formula, and the product was tested.

[0076] It has been detected that the obtained ceramic element is in the FE phase at room temperature, and the phase transition of the ceramic element will only occur under temperature induction, and the phase transition that occurs is FE-AFE phase transition.

[0077] The ceramic element of this embodiment was tested for the pyroelectric performance after the polarization treatment, and the test results are shown in Table 1, and the pyroelectric peak value p max More than 450×10 -8 C·cm -2 ·K -1 , for 458×10 -8 C·cm -2 ·K -1 .

[0078] The ceramic element of this embodiment has been tested on the pyroelectric performance and thermal hysteresis of temperature rise and fall under the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com