Novel ceramic material having electric-field enhancement pyroelectric property and wide temperature range electrocaloric effect and preparation method thereof

A technology of ceramic materials and electric card effect, which is applied in the field of electric card ceramic materials and its preparation, and field-enhanced pyroelectricity, can solve problems such as application limitations, and achieve large pyroelectric response and field-enhanced pyroelectricity Great performance and pyroelectric response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

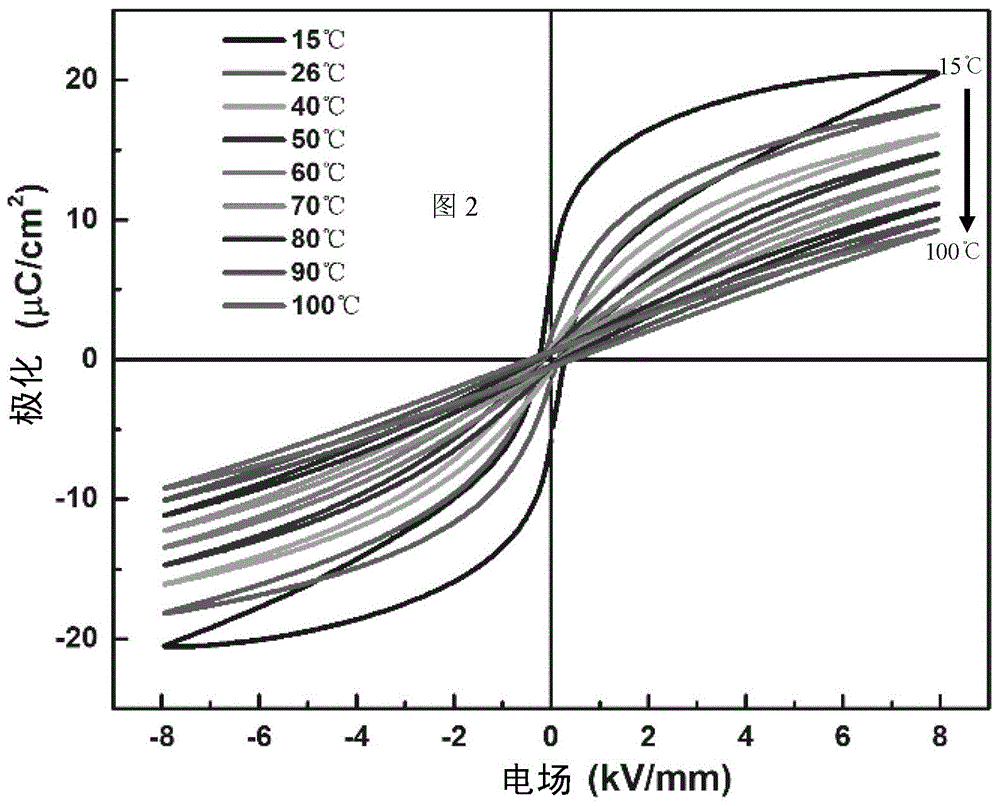

[0054] A new type of ceramic material with both field-enhanced pyroelectric performance and wide temperature zone electric card effect is composed of:

[0055] Pb 0.3 Ca 0.05 Sr 0.65 TiO 3

[0056] (1) Calculate the composition Pb in the raw material according to the above chemical formula 3 o 4 , CaCO 3 , SrCO 3 and TiO 2 The mass is prepared according to the composition ratio, mixed by wet ball milling, and mixed for 24 hours according to the mass ratio of raw materials: ball: water = 1:1.7:1.2, so that the components are mixed evenly. After drying, pass through a 30-mesh sieve, briquette in an air atmosphere, raise the temperature to 900°C at a rate of 2°C / min, and keep the temperature for 2 hours for synthesis.

[0057] (2) smash the ceramic block obtained in step (1), pass through a 40-mesh sieve, and then finely grind for 48 hours by wet ball milling, dry the finely ground ceramic powder, and then add 8wt.% of the powder weight PVA binder, granulated, aged for 24...

Embodiment 2

[0069] The composition of new ceramic materials with both field-enhanced pyroelectric performance and wide temperature zone electric card effect is as follows:

[0070] Pb 0.3 Ca 0.15 Sr 0.55 TiO 3

[0071] The preparation method of Example 1 was repeated according to the above formula, except that the temperature was raised to 1260° C. for sintering at a rate of 2° C. / min during the sintering process.

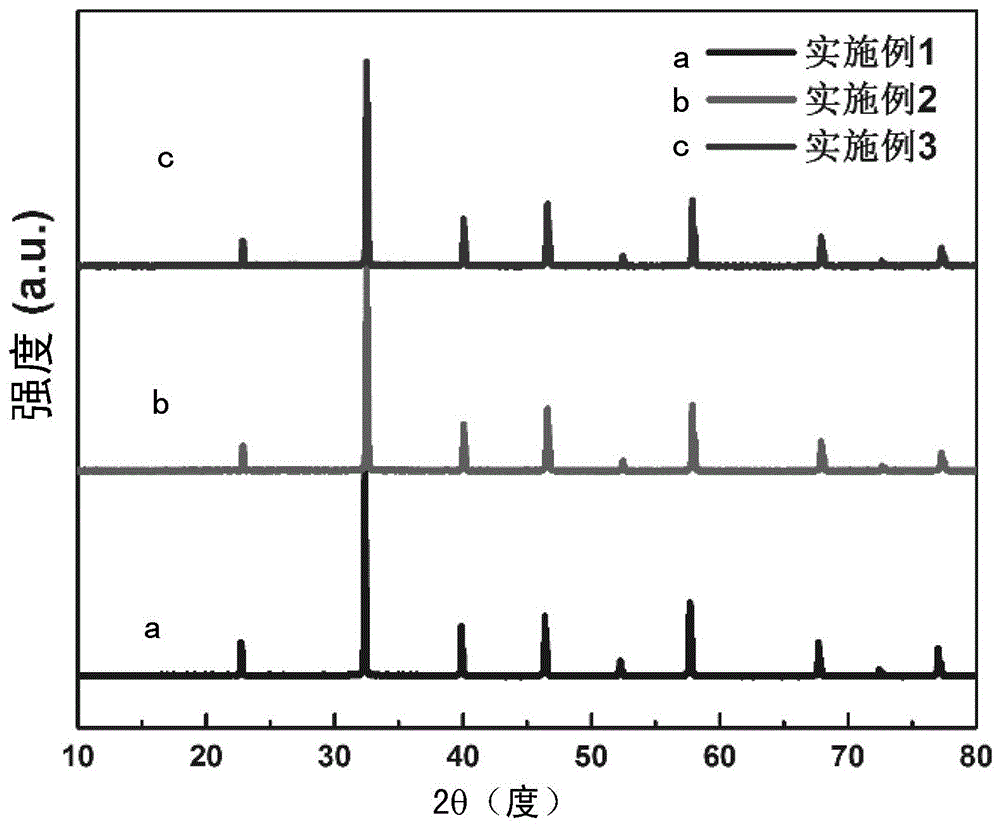

[0072] Carry out room temperature XRD test to the ceramic sample of present embodiment, the result sees Figure 10 , which is a standard ternary solid solution of perovskite structure without other impurity phases.

[0073] Dielectric thermograms and off-field pyroelectric coefficients were measured for the ceramic samples of this example, and the results are shown in Fig. 4(a) and Fig. 4(b). According to its dielectric spectrum, the Curie temperature of the sample is 5°C, which is close to room temperature. By component preference, under an electric field of 200V / mm, P...

Embodiment 3

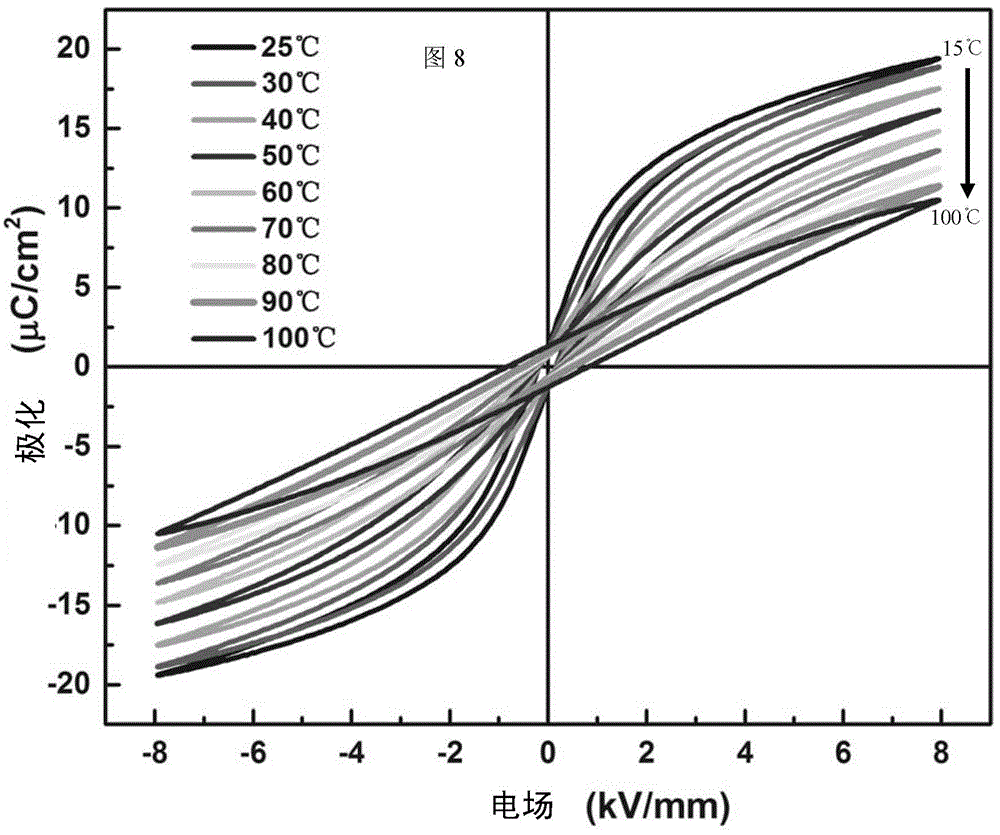

[0076] The composition of new ceramic materials with both field-enhanced pyroelectric performance and wide temperature zone electric card effect is as follows:

[0077] Pb 0.325 Ca 0.15 Sr 0.525 TiO 3

[0078] The preparation method of Example 1 was repeated according to the above formula, except that the temperature was raised to 1300° C. at a rate of 2° C. / min during the sintering process.

[0079] Carry out room temperature XRD test to the ceramic sample of present embodiment, the result sees Figure 10 , which is a standard ternary solid solution of perovskite structure without other impurity phases.

[0080] Dielectric thermograms and off-field pyroelectric coefficients were measured for the ceramic samples of this example, and the results are shown in Fig. 7(a) and Fig. 7(b). From Figure 7(a) and Figure 7(b), it can be seen that the Curie temperature of the sample is 21°C, and the pyroelectric coefficient of the sample is 72×10 under a bias electric field of 200V / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com