Thin film material with high electrocaloric effect near room temperature and preparation method thereof

A technology of thin film materials and electric card effect, applied in the direction of machines using electric/magnetic effects, manufacturing/processing of electromagnetic devices, material selection, etc., can solve problems such as hazards and inability to meet the practical application of electric card effect, and achieve a wide range Application prospects, widening the working temperature range, and the effect of high power card temperature change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

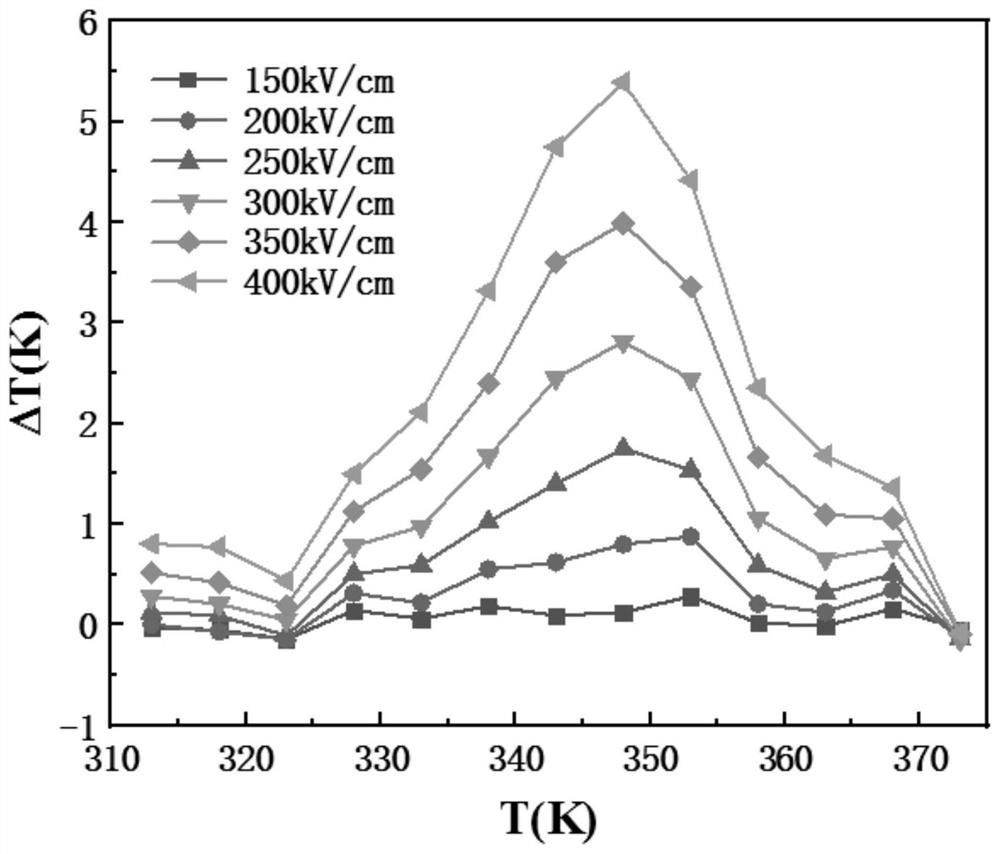

[0028] A (1-x)Ba(Ti 0.8 Zr 0.2 )O 3 -x(Ba 0.7 Ca 0.3 )TiO 3 Thin film, x takes the value of 0.32,0.5 respectively, and its preparation method comprises the following steps:

[0029] 1) Using barium acetate, calcium acetate, zirconium n-propoxide, and tetrabutyl titanate as raw materials, according to the x value of 0.32 and 0.5 (1-x)Ba(Ti 0.8 Zr 0.2 )O 3 -x(Ba 0.7 Ca 0.3 )TiO 3 The stoichiometric ratio, calculate and weigh the corresponding raw materials;

[0030]2) Dissolve the weighed barium acetate and calcium acetate in acetic acid, stir at 50-60°C until completely dissolved to obtain solution A, dissolve zirconium n-propoxide in ethylene glycol methyl ether, stir at room temperature until completely dissolved , and then mix the obtained zirconium n-propoxide solution with solution A, stir at 50°C for 1 hour and then cool to room temperature to obtain solution B, add tetrabutyl titanate to solution B and mix well, dilute with ethylene glycol methyl ether to (1-...

Embodiment 3~6

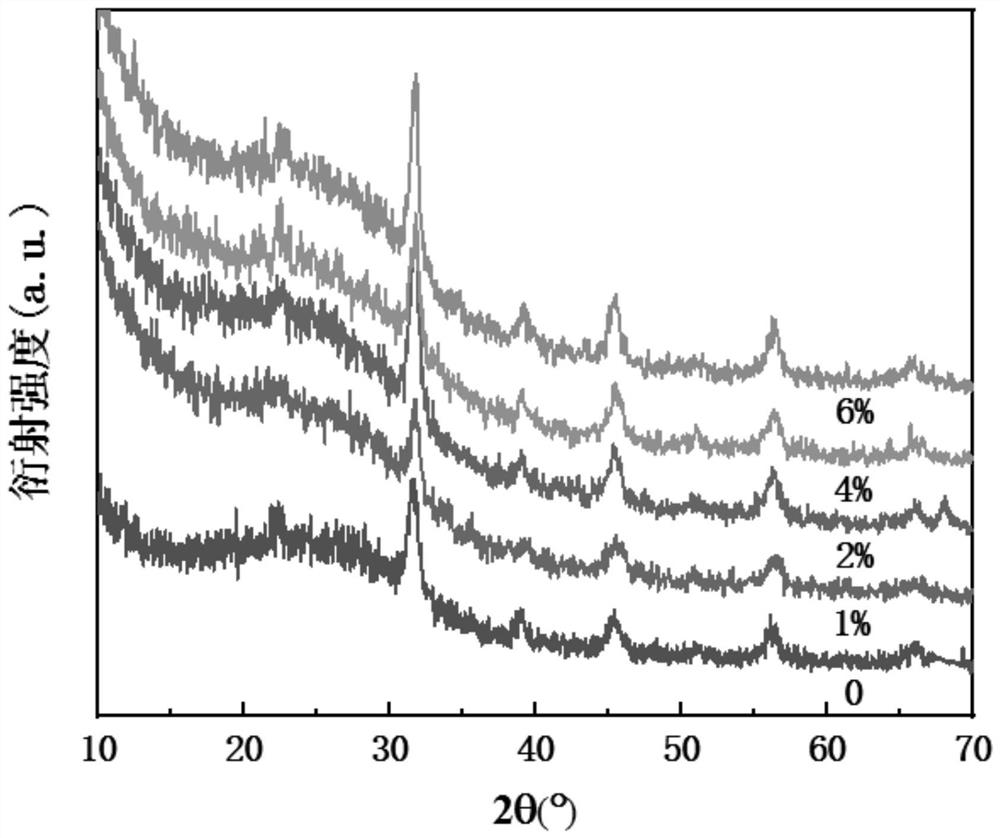

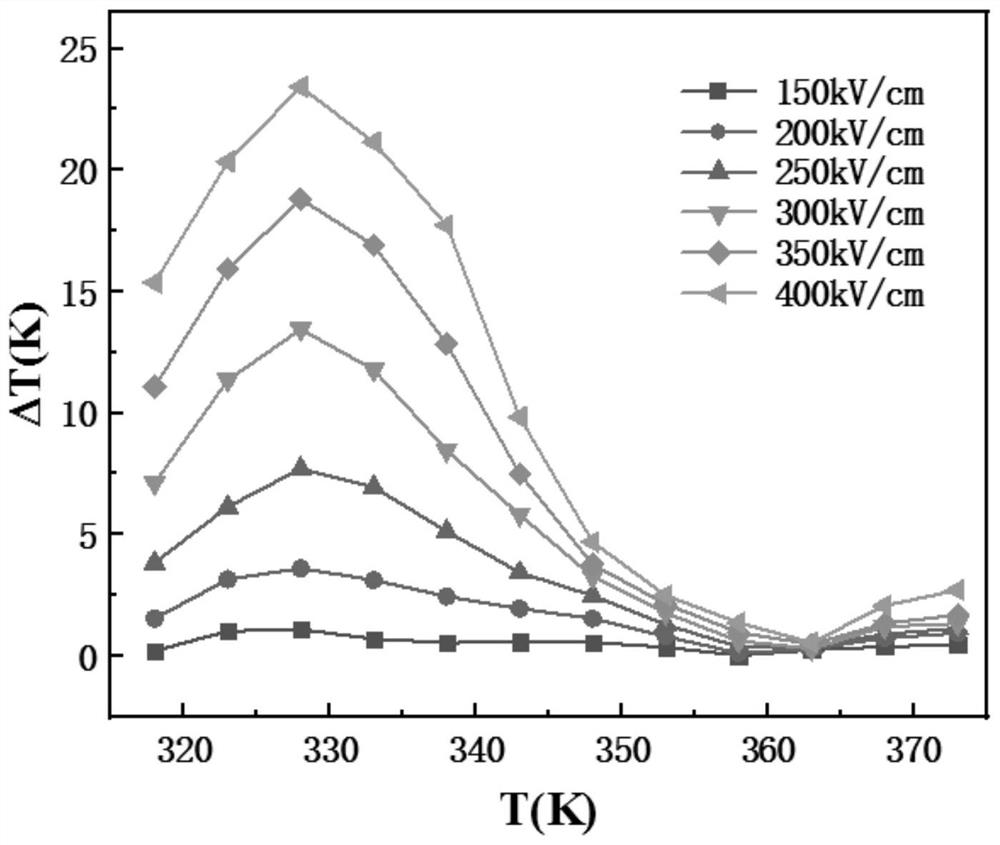

[0042] A 0.68Ba(Ti 0.8 Zr 0.2 )O 3 -0.32 (Ba 0.7 Ca 0.3 )TiO 3 -ySn film, the value of y is respectively 0.01, 0.02, 0.04, 0.06, and its preparation method comprises the following steps:

[0043] 1) Using barium acetate, calcium acetate, zirconium n-propoxide, tin acetate, and tetrabutyl titanate as raw materials, according to y values of 0.01, 0.02, 0.04, and 0.06, 0.68Ba(Ti 0.8 Zr 0.2 )O 3 -0.32 (Ba 0.7 Ca 0.3 )TiO 3 - The stoichiometric ratio of ySn, calculate and weigh the corresponding raw materials;

[0044] 2) Dissolve the weighed tin acetate in acetic acid, stir at 70-80°C for 30-60min, then add barium acetate and calcium acetate and stir at 40-50°C until clear to obtain solution A, add zirconium n-propoxide Dissolve in ethylene glycol methyl ether, stir at room temperature until completely dissolved, then mix the obtained zirconium n-propoxide solution with solution A, stir at 50°C for 1 hour and cool to room temperature to obtain solution B, tetrabutyl t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com