BaTiO3-based electrocaloric material with good temperature stability near room temperature as well as preparation method and application of BaTiO3-based electrocaloric material

A stable, room temperature technology, applied in the field of BaTiO3-based electric card materials and its preparation, can solve the problems of weak electric card response, high response temperature of ferroelectric ceramic electric card, poor temperature stability near room temperature, etc., to avoid pollution, The effect of improving the response intensity and the preparation method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

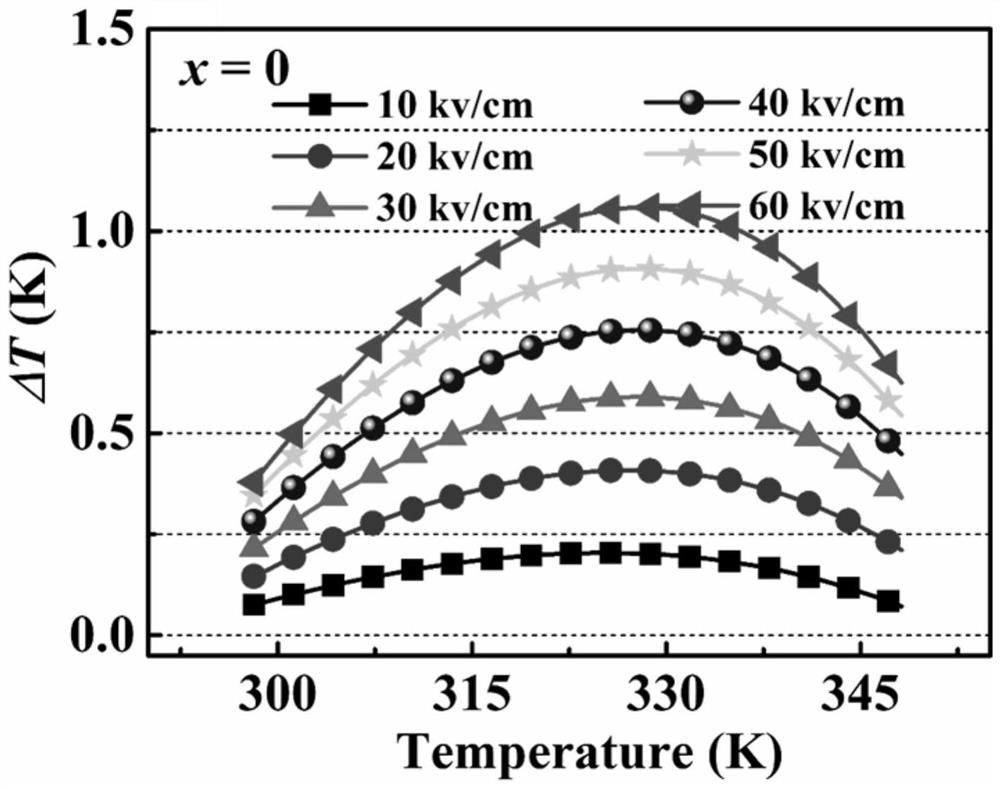

Embodiment 1

[0034] a Ba 1-x La x Ti 0.9 sn 0.1 o 3 Electric card material, the value of x is 0, that is, the chemical formula is BaTi 0.9 sn 0.1 o 3 , its preparation method comprises the following steps:

[0035] 1) BaCO 3 , La 2 o 3 、TiO 2 and SnO 2 Raw material according to Ba 1-x La x Ti 0.9 sn 0.1 o 3 Stoichiometric weighing, using a planetary ball mill for mixed ball milling, and ball milling at a speed of 300r / min for 8 hours to obtain uniformly mixed raw material powder;

[0036] 2) The raw material powder obtained in step 1) is dried and then calcined to obtain a calcined block, wherein the calcining is carried out in a box furnace from room temperature to 1200°C at a heating rate of 5°C / min, and after holding for 2 hours, the The temperature rate was 5°C / min to cool down to 500°C, and then naturally cooled to room temperature.

[0037] 3) The calcined block obtained in step 2) is ball milled again, the ball milling process is the same as step 1), and then dried...

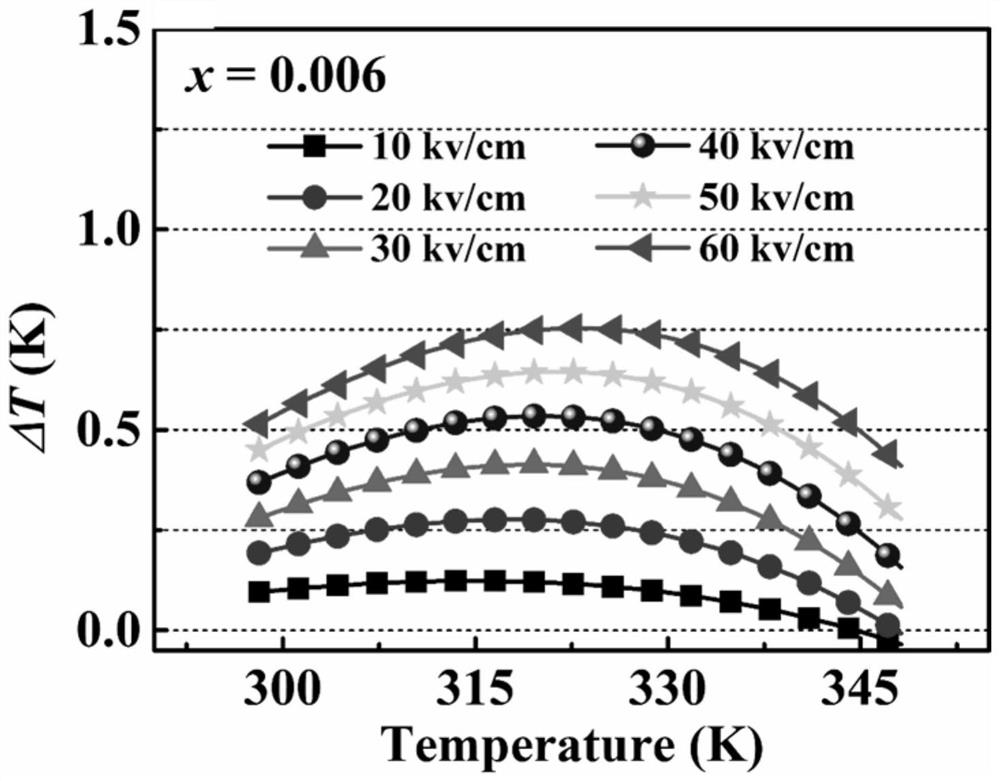

Embodiment 2

[0041] a Ba 1-x La x Ti 0.9 sn 0.1 o 3 Electric card material, the value of x is 0.006, that is, the chemical formula is Ba 0.994 La 0.006 Ti 0.9 sn 0.1 o 3 , its preparation method comprises the following steps:

[0042] 1) BaCO 3 , La 2 o 3 、TiO 2 and SnO 2 Raw material according to Ba 1-x La x Ti 0.9 sn 0.1 o 3 Stoichiometric weighing, using a planetary ball mill for mixed ball milling, and ball milling at a speed of 300r / min for 8 hours to obtain uniformly mixed raw material powder;

[0043] 2) The raw material powder obtained in step 1) is dried and then calcined to obtain a calcined block, wherein the calcining is carried out in a box furnace from room temperature to 1200°C at a heating rate of 5°C / min, and after holding for 2 hours, the The temperature rate was 5°C / min to cool down to 500°C, and then naturally cooled to room temperature.

[0044] 3) The calcined block obtained in step 2) is ball milled again, the ball milling process is the same as s...

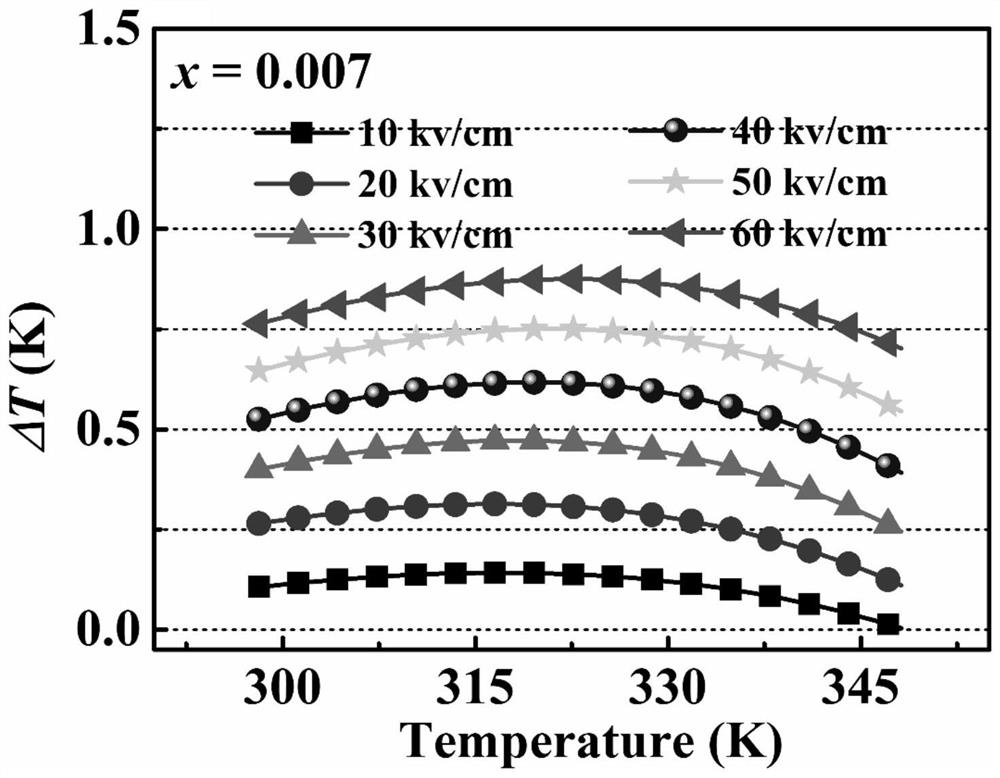

Embodiment 3

[0048] a Ba 1-x La x Ti 0.9 sn 0.1 o 3 Electric card material, the value of x is 0.007, that is, the chemical formula is Ba 0.993 La 0.007 Ti 0.9 sn 0.1 o 3 , its preparation method comprises the following steps:

[0049] 1) BaCO 3 , La 2 o 3 、TiO 2 and SnO 2 Raw material according to Ba 1-x La x Ti 0.9 sn 0.1 o 3 Stoichiometric weighing, using a planetary ball mill for mixed ball milling, and ball milling at a speed of 300r / min for 8 hours to obtain uniformly mixed raw material powder;

[0050] 2) The raw material powder obtained in step 1) is dried and then calcined to obtain a calcined block, wherein the calcining is carried out in a box furnace from room temperature to 1200°C at a heating rate of 5°C / min, and after holding for 2 hours, the The temperature rate was 5°C / min to cool down to 500°C, and then naturally cooled to room temperature.

[0051] 3) The calcined block obtained in step 2) is ball milled again, the ball milling process is the same as s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com