Spring lock without spring

A marble lock and marble technology, applied in the field of marble locks, can solve the problems that the spring is easy to rust, cannot be used, and cannot be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

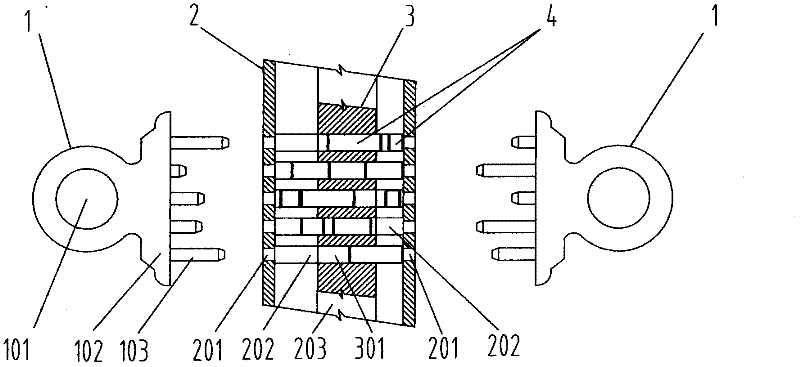

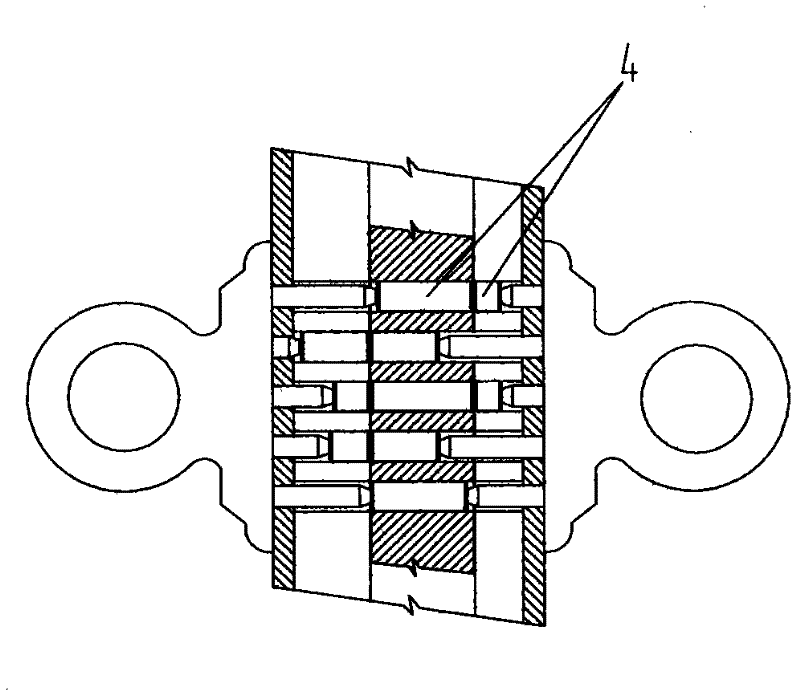

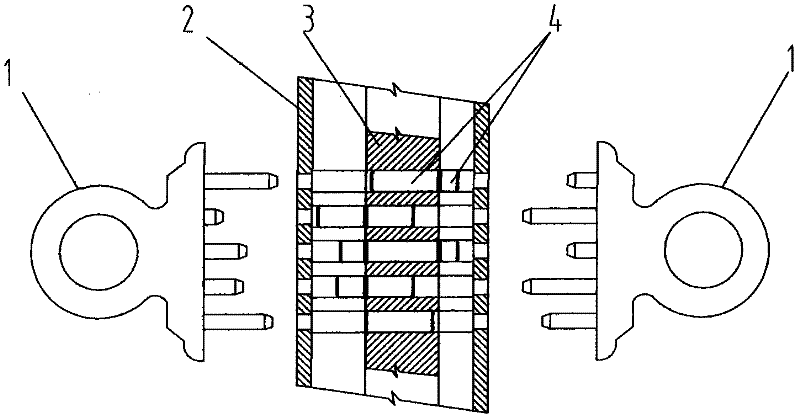

[0058] Such as Figure 1-5 As shown, a springless pin lock composed of a lock body, a lock cylinder, a pin and a paired key is characterized in that there is a lock cylinder groove (203) in the lock body (2), and at least one Concentric corresponding pin hole (202), lock body (2) two outsides have (key) post tooth hole (201) concentric corresponding with pin pin hole (202), the diameter of (key) post tooth hole (201) is less than Pin (4) diameter; the lock cylinder (3) is drilled horizontally with a pin hole (301) with the same diameter as the pin hole (202) of the lock body (2) and concentrically corresponding; each lock is equipped with a pin hole (301) corresponding to Two keys (1), the post teeth (103) of one key (1) are unlocking teeth, the corresponding post teeth (103) of the other key (1) are thrust teeth, and the corresponding post teeth (103) of the two keys (1) are The lengths of the teeth (103) are complementary, so that the interface between the pins (4) in the s...

Embodiment 2

[0060] Such as Figure 4 , 10 As shown, the lock core that the present invention relates to is characterized in that the lock core (3) is a slider structure, there is a push handle (303) on the lock core (3), and the lock core (3) is drilled with a lock body (2) horizontally. The concentric pinholes (301) corresponding to the pinhole holes (202) with the same diameter; the lock core (3) can slide left and right in the lock core groove (203).

Embodiment 3

[0062] Such as Figure 6-11 Shown, according to embodiment 1, 2, a kind of lock body and (lock cylinder) bottom box, slider lock cylinder, belt tray, marble, paired key are made up of lock belt springless pin lock, It is characterized in that the lock cylinder (3) is a slider structure, there is a push handle (303) on the lock cylinder (3) and a lock pin (302) at the end, and the lock cylinder (3) is sealed and clamped between the lock body (2) and the lock body (2). Between the lock cylinder grooves (203) on the inside of the bottom box (207); the top surface of the lock body (2) has a push handle (303) hollow chute (204), and the left end inside of the lock body (2) has a lock groove ( 206), there is a lock body (2) respin (205) in the lower side of the right end; ) is concentrically corresponding to the lock cylinder (3) marble hole (301); the left end of the belt (6) tray (5) has a lock (501), and at least one tooth post (502) is arranged on the tray (5), and the tray ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com