Monitoring method of strip mine excavator loading process based on images and apparatus thereof

A technology for excavators and open-pit mines, applied in the field of monitoring the loading process of open-pit mine excavators, can solve problems such as miscalculation, unbalanced loading and unloading quantities, and automatic statistical assessment of loading time, etc., to improve Process efficiency, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

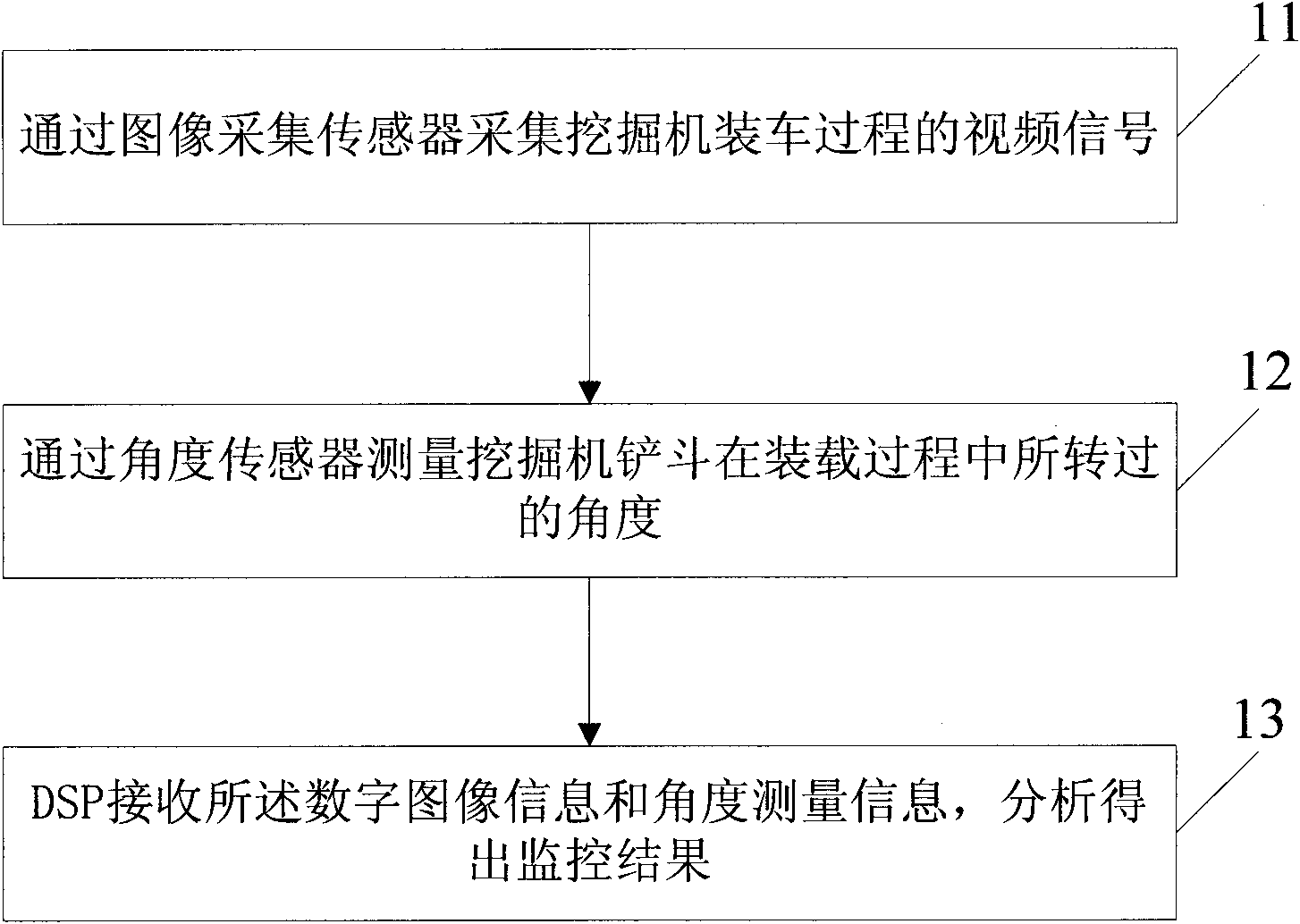

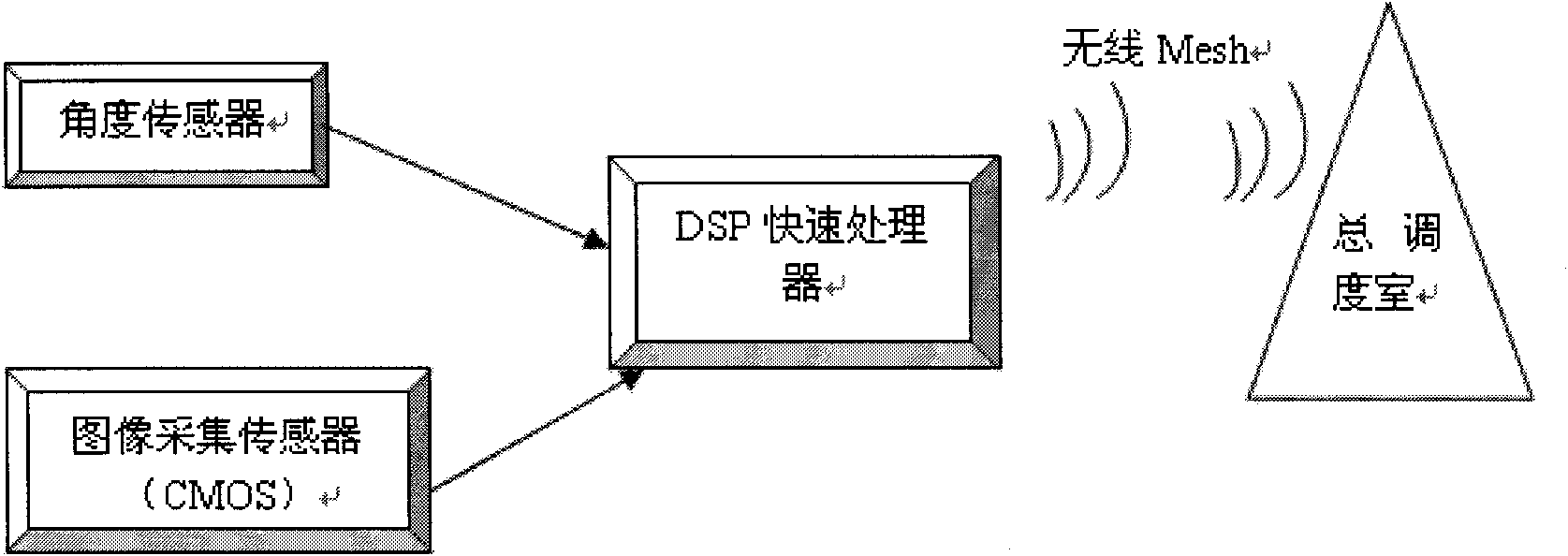

[0022] The embodiment of the present invention provides an image-based monitoring method and device for the loading process of an excavator in an open-pit mine, using machine vision recognition technology and the technology of measuring the rotation angle of the excavator bucket to realize the excavation position of the bucket during the loading process , the full load of the bucket, the moving angle of the bucket, the identification of the truck number, the number of loading buckets, and the fullness of the truck (loading volume) and the loading time of the excavator for effective image process analysis, according to The mining process completes machine vision recognition, thereby realizing the automatic supervision of the excavator loading process in the open-pit mine, saving the corresponding manpower and material resources, and improving the efficiency of the shovel loading process in the open-pit mine.

[0023] In order to better describe the embodiments of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com