Enamelling machine with mechanism for exciting and purifying tail gas physically and chemically

A technology of physical chemistry and enamelling machine, applied in the direction of conductor/cable insulation, etc., can solve stringent environmental protection problems, achieve the effect of solving exhaust gas fine purification technology problems, and completely eliminating trace organic pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

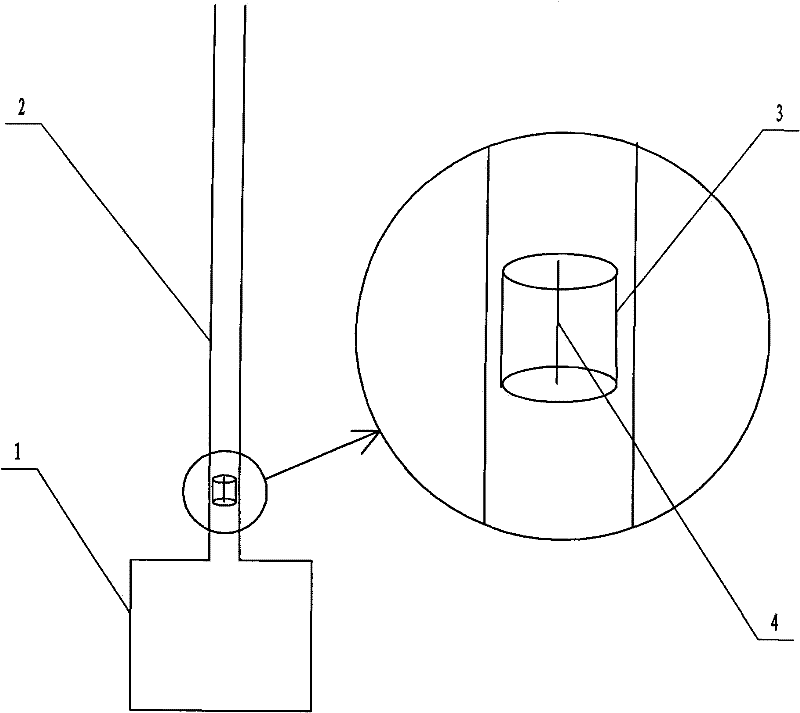

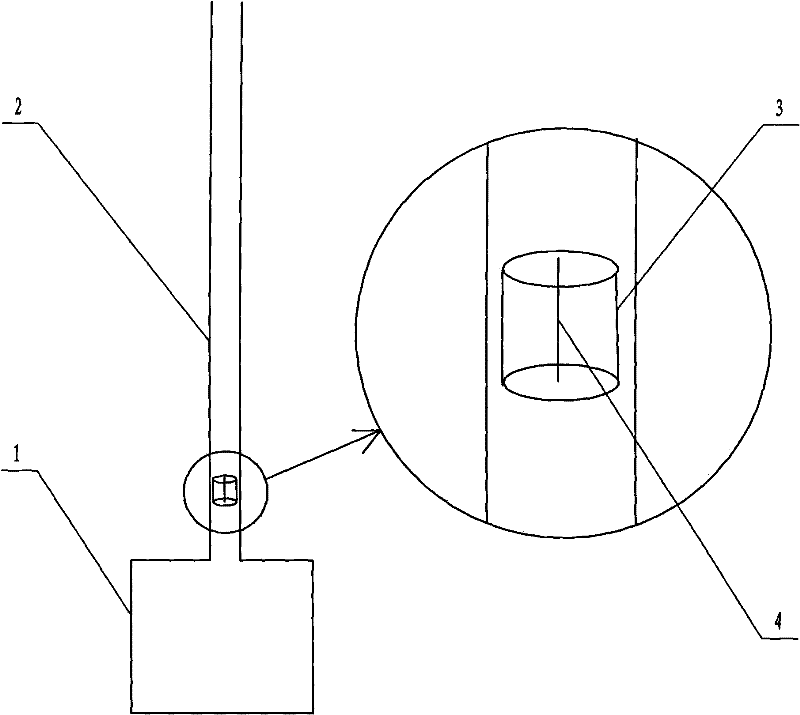

[0011] exist figure 1 In the embodiment of the case shown schematically, the structure of the enamelling machine 1 includes an exhaust gas discharge pipe 2. The point is that the structure of the enamelling machine 1 also includes corona electrodes 3, 4, and the installation positions of the corona electrodes 3, 4 are in The interior of the exhaust gas discharge pipe 2. The structure of this embodiment can of course also include the spray cooling device installed at the final release port position of the exhaust gas discharge pipeline of the enamelling machine that is not drawn in the figure, and the final release port position of the exhaust gas discharge pipeline of the enamelling machine is installed Organic concentration monitoring alarm, and other accessories. The spray cooling device is not necessary. The organic concentration monitoring alarm is also not necessary.

[0012] The form of the corona electrode is not limited to the style in the legend, and can be any oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com