Enamelling machine cluster having a package of fine processing mechanisms of tail gas

An enameling machine, a package of technologies, applied in electrical components, circuits, and conductor/cable insulation, etc., to avoid secondary pollution, completely eliminate trace organic pollutants, and solve the technical problems of fine purification of exhaust gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

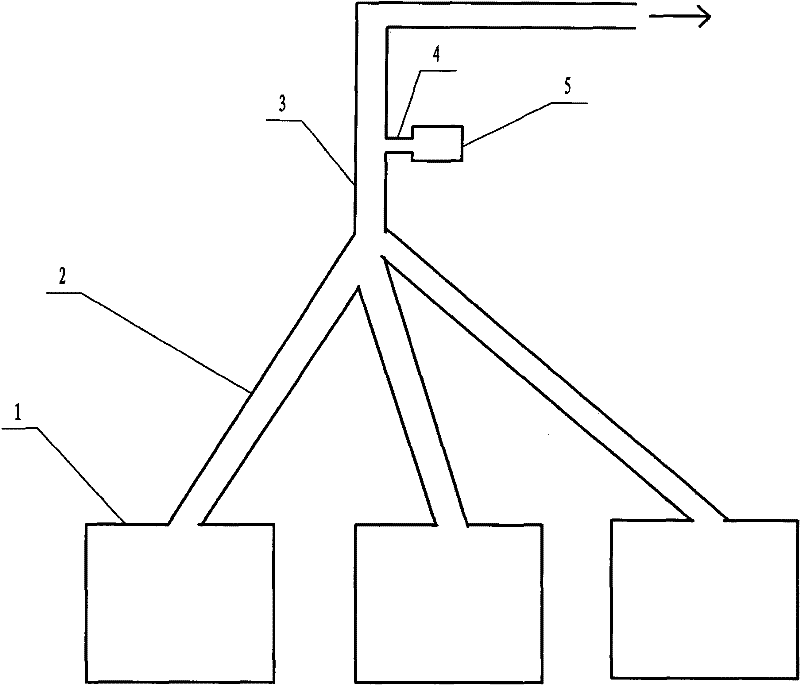

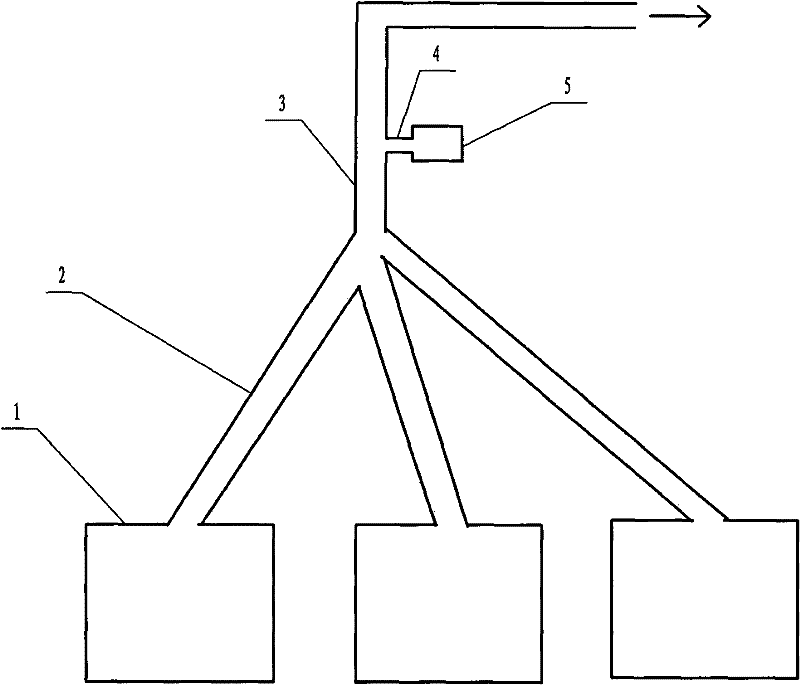

[0017] exist figure 1 In the example of the case shown schematically, the enamelling machine cluster contains three enameled wire ovens such as the enameled wire oven 1, and the tail gas discharge pipe 2 of each enameled wire oven 1 in the enamelling machine cluster is connected to the enamelled wire oven. The tail gas collection pipeline 3 of the charter machine cluster is connected, and the tail gas collection pipeline 3 is used to collect and discharge the tail gas of all enameled wire ovens 1 in the enamelling machine cluster. The point is that the structure of the enamelling machine cluster also includes an ozone machine 5, and the ozone The machine 5 is an ozone generating device, and the ozone discharge channel 4 of the ozone machine 5 communicates with the tail gas collecting pipeline 3 of the enamelling machine cluster. The structure of this embodiment can of course also include the spray cooling device installed at the final release port position of the exhaust gas d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com