Method for synchronously measuring structural rigidity in guy cable structure construction

A technology for structural stiffness and construction, which is applied in the field of stiffness measurement of cable structures, and can solve problems such as the stiffness measurement technology of large-scale cable structures that have not yet been seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] A method for synchronously measuring structural stiffness in cable structure construction, the method comprising the following steps:

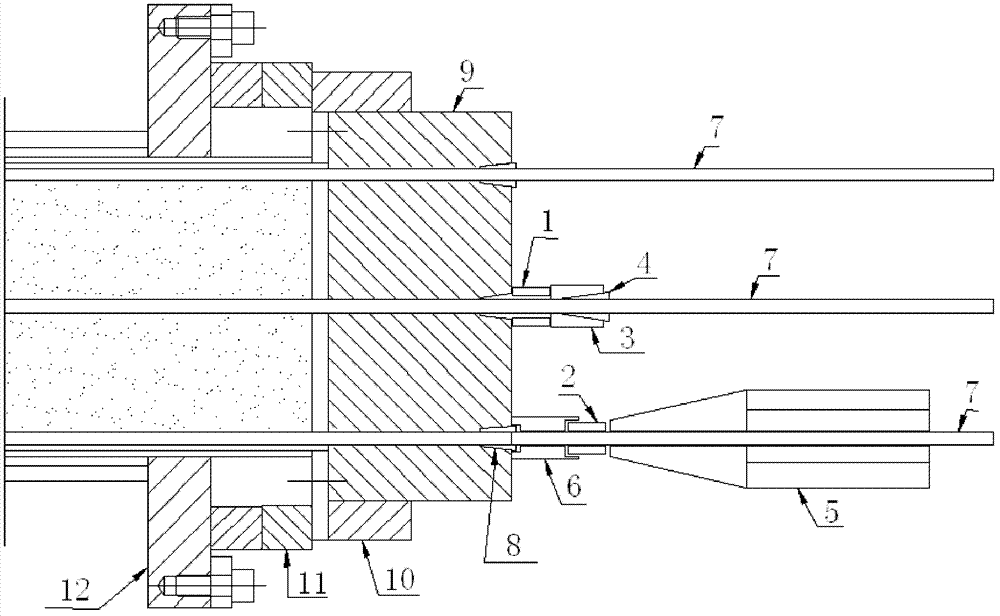

[0027] Such as figure 1 As shown, select two pressure sensors ( figure 1 "1" and "2"), a single-hole clip tool anchor (by figure 1 "3" and "4") and a hand jack ( figure 1 middle "5"), using high-strength steel to make a tool presser ( figure 1 middle "6"), wherein the pressure sensor can be a vibration-type or fiber grating type anchor cable dynamometer (such as the BGK-4900 vibration-type anchor cable dynamometer or BGK-FBG produced by Beijing Jikang Technology Co., Ltd. -4900 fiber grating type anchor cable dynamometer), the production of the tool jacking device can be made by the manufacturer of the hand-held jack (for example, the YDQ type front clamping jack produced by Liuzhou Wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com