Ball spinning forming tooling device and reverse ball spinning forming method thereof

A ball and shape technology, applied in the field of ball spinning forming tooling device and its reverse ball spinning forming, to achieve the effect of simple tooling, light equipment and small deformation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in more detail below in conjunction with accompanying drawing example:

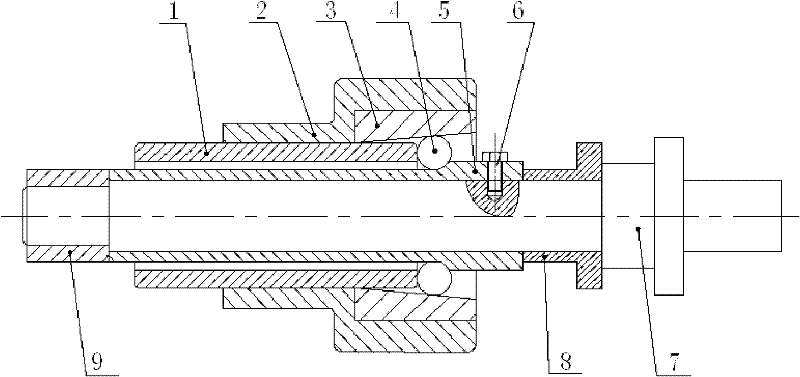

[0029] combine Figure 1-7 , Ball spinning forming process scheme Ball spinning is carried out on a common lathe, the spinning head in the ball spinning tooling is clamped on the main shaft of the lathe, and the mandrel with the blank is installed on the tail top of the lathe, The spinning head rotates at high speed with the spindle of the lathe, and the core mold with the blank is fed axially with the tail top of the lathe, and the axial flow of the blank on the core mold is restricted, which is conducive to filling the inner ribs.

[0030] Ball spinning tooling structure The tooling includes three parts: spinning head, mandrel and restraint device, such as figure 1 shown.

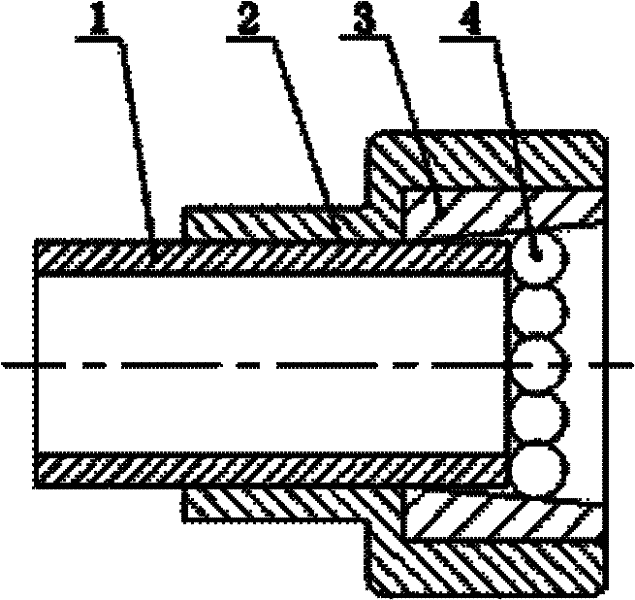

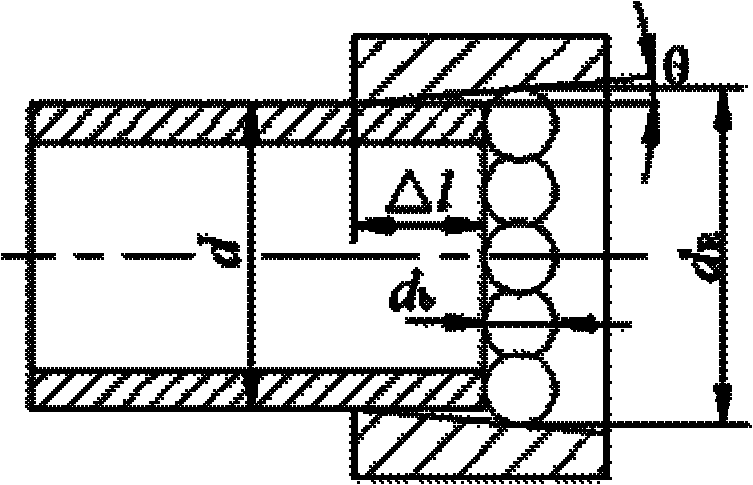

[0031] The spinning head part is composed of threaded support tube 1, outer support ring 2, conical die ring 3 and ball 4, such as figure 2 . The outer surface of the threaded support pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com