Ball hot spinning forming device and method for nickel titanium shape memory alloy thin-walled pipe

A technology of memory alloy and thin-walled tubes, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unfavorable manufacturing of extremely thin-walled nickel-titanium shape memory tubes, tube fractures, etc., to save the number of tooling, reduce deformation resistance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

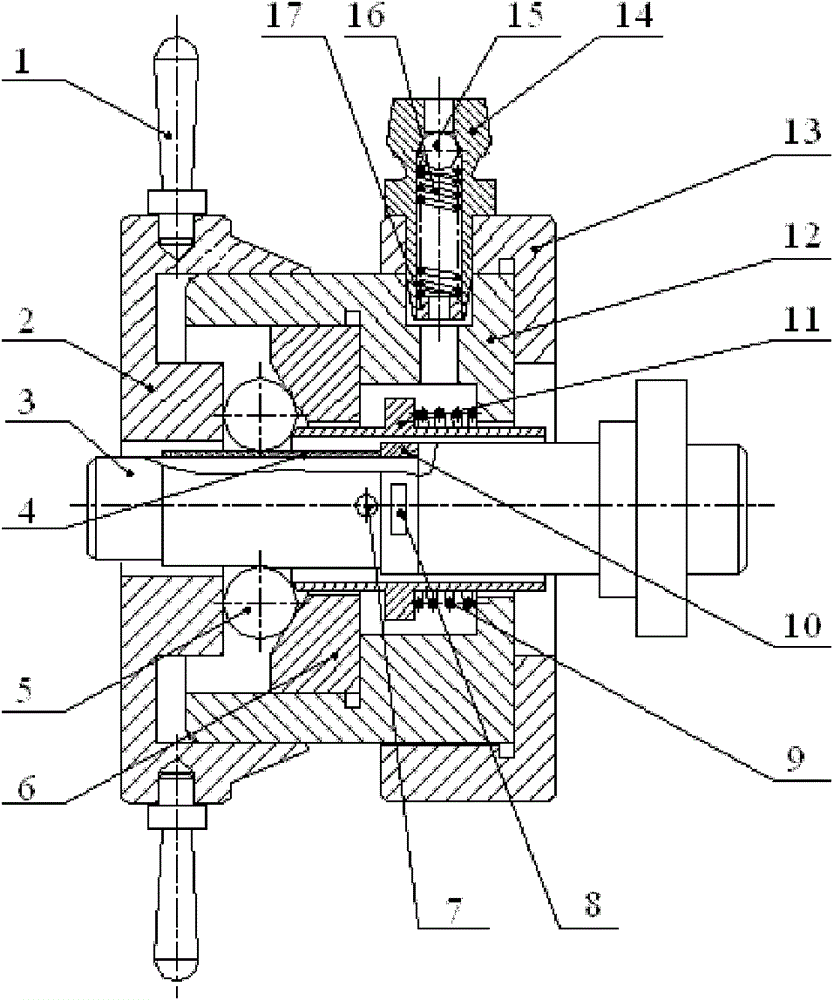

[0026] to combine figure 1 , Nickel-titanium shape memory alloy thin-walled tube ball hot spinning device includes three parts: spinning head, core mold and unloading device.

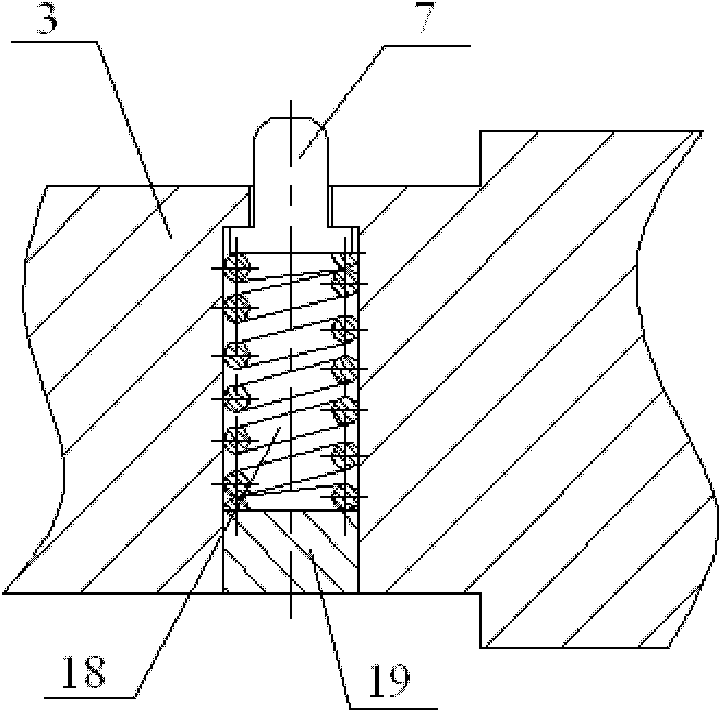

[0027] The spinning head part is composed of handle 1, knob 2, ball 5, mold ring 6, spring 9, cage 11, bracket 12, housing 13, nozzle 14, ball valve 15, spring 16 and retaining ring 17. There are two handles 1, which are connected with the knob 2 by threads; two threaded holes are opened on the outer surface of the knob 2 for screwing in the two handles, the inner surface is connected with the bracket 12 by threads, and the outer tapered surface of the knob 2 is marked Corresponding to the marked line on the outer surface of the bracket 12, the radial adjustment amount of the ball can be read; the mold ring 6 and the bracket 12 are interference fit; the balls 5 are evenly distributed along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com