Thin type lock

A lock, thin technology, applied in the direction of building locks, lock shells, cylinder pin locks, etc., can solve the problem that the width of the lock is difficult to be further reduced, and the thin door panel cannot be applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

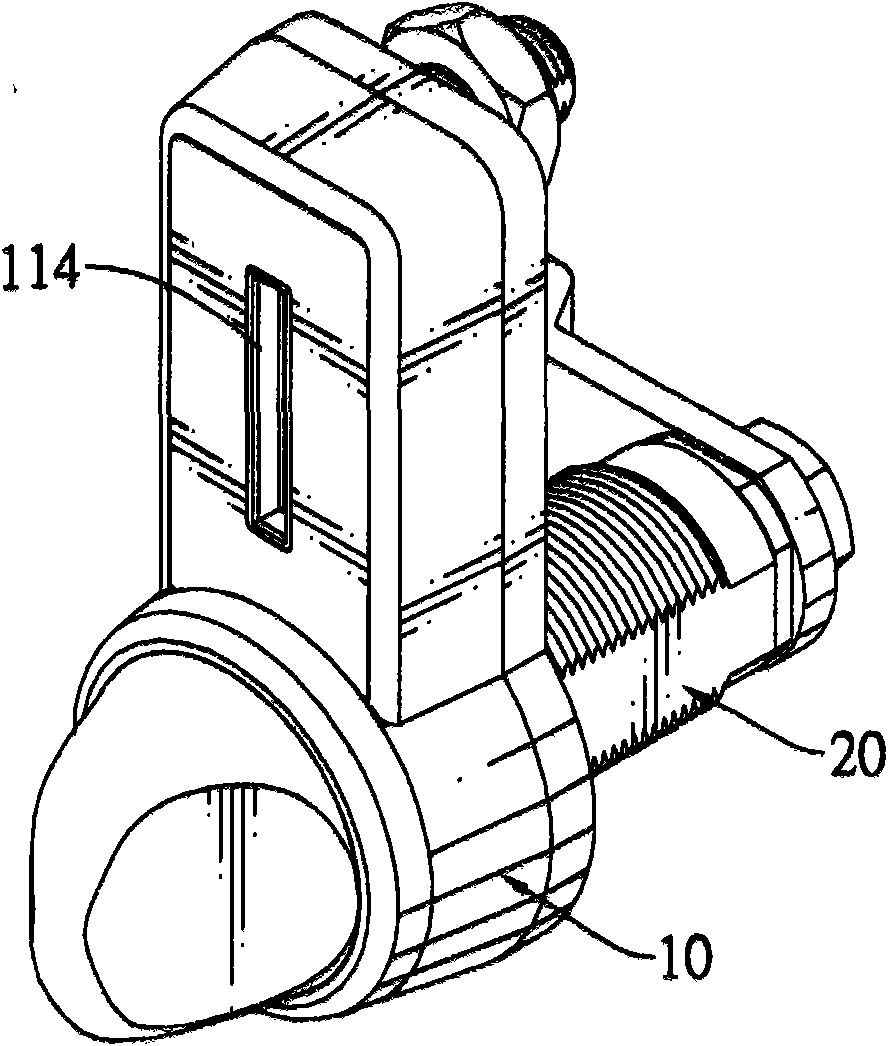

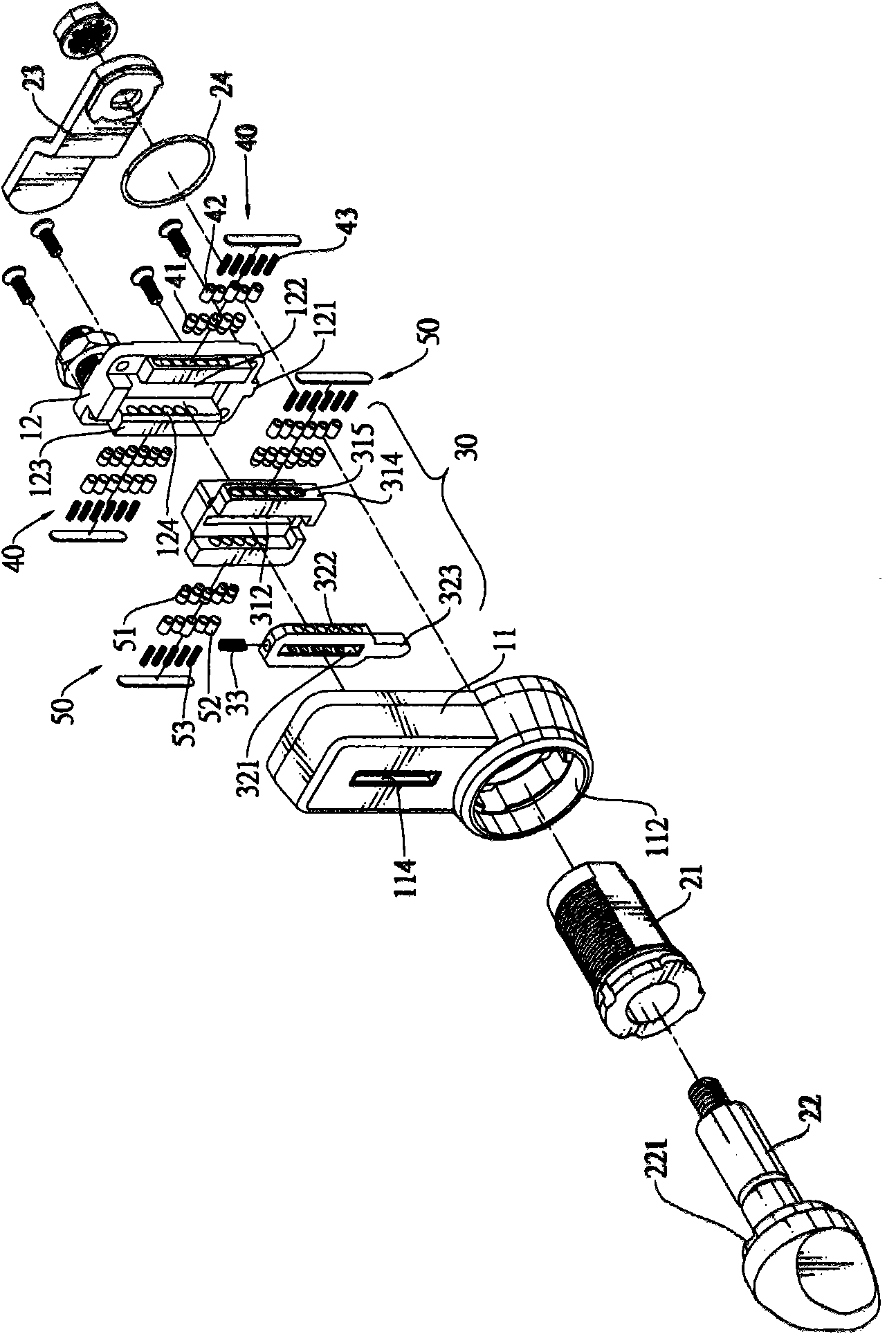

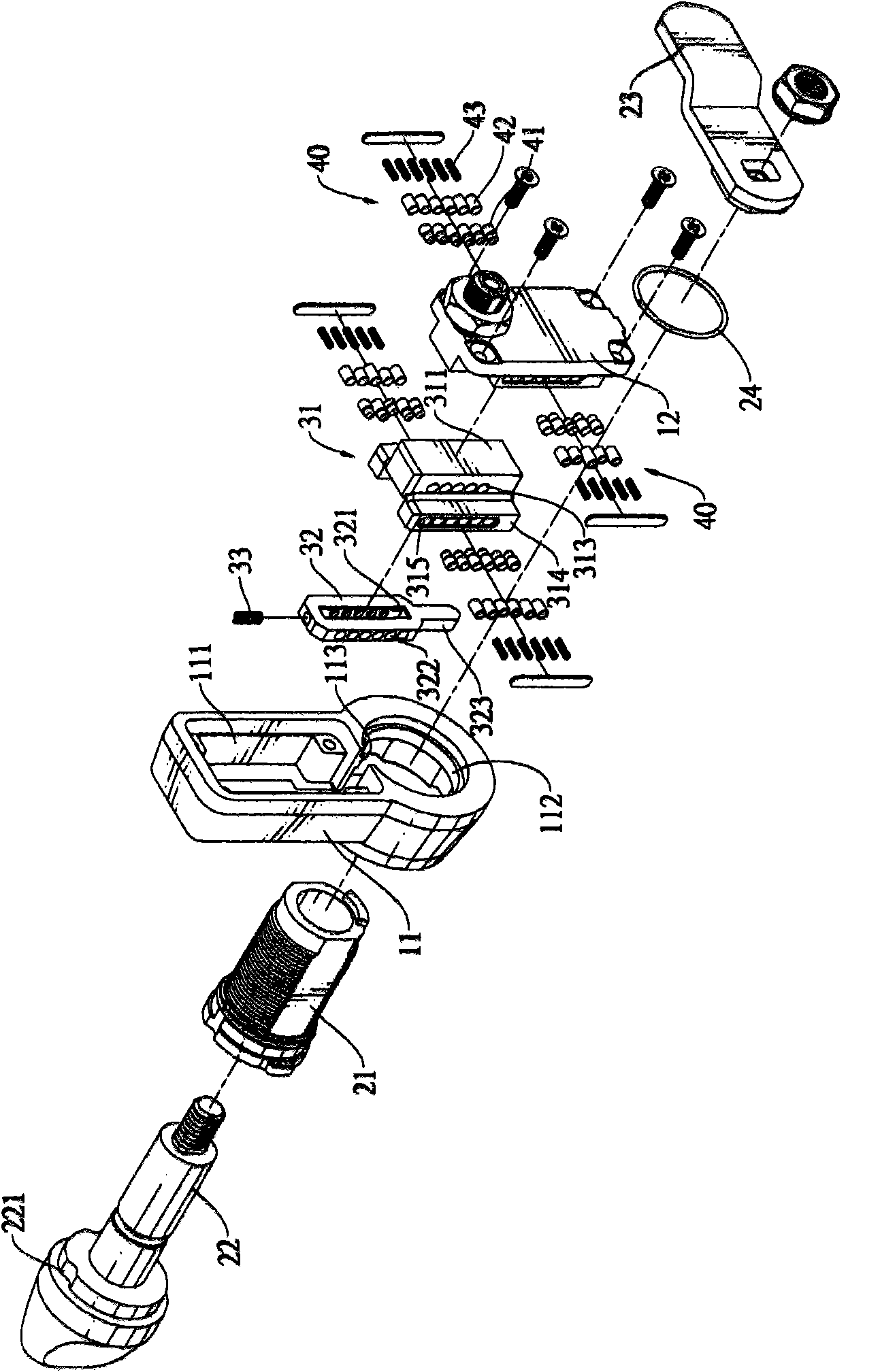

[0057] see figure 1 and figure 2The first embodiment of the thin lockset of the present invention is shown, which comprises a hollow lock case 10, a lock bolt assembly 20, a bead seat assembly 30, a main elastic member 33, a plurality of first lock cylinder assemblies 40 and a plurality of The second lock cylinder assembly 50, wherein:

[0058] The lock case 10 includes a front case 11 and a rear case 12;

[0059] Cooperate see image 3 As shown, a lock core groove 111, a lock bolt hole 112 and a key insertion hole 114 are formed on the front shell 11, the lock core groove 111 is formed on a rear side of the front shell 11, and the lock bolt hole 112 Through-molding is formed between a front side and a rear side of the front housing 11, and communicates with the lock core groove 111 through a through hole 113. The key insertion hole 114 is formed through the front side of the front housing 11 and correspondingly The lock core groove 111, and communicate with the lock core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com