Method and device for detecting power battery insulation resistance of electric automobile

A technology of insulation resistance and power battery, applied in measuring devices, measuring resistance/reactance/impedance, measuring electricity, etc., can solve the problem of inability to locate the leakage position, and achieve the effect of eliminating inaccurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

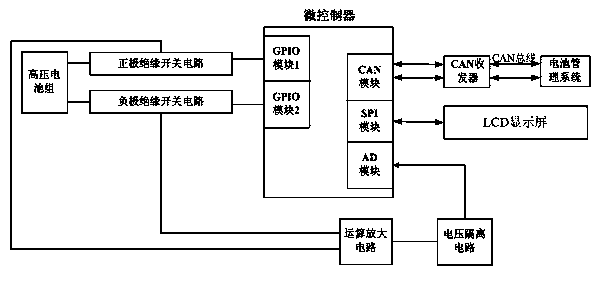

[0034] Such as figure 1 Shown: The power battery insulation resistance detection device is mainly composed of a microcontroller (MCU-Micro Control Unit), a positive insulation switch circuit, a negative insulation switch circuit, an operational amplifier circuit, a voltage isolation circuit, and a CAN-Controller Area Network. ) Transceiver and LCD display. Among them, the GPIO-General Purpose Input Output (GPIO-General Purpose Input Output) module 1 of the MCU is externally connected to the control terminal of the positive insulated optocoupler relay, and the GPIO module 2 of the MCU is connected to the control terminal of the negative insulated optocoupler relay. Select the conduction logic to output the insulation resistance sampling voltage. After the insulation resistance sampling voltage is processed by the operational amplifier circuit, it enters the voltage isolation circuit for voltage isolation processing. Finally, input to the analog-to-digital conversion (AD-Anal...

Embodiment 2

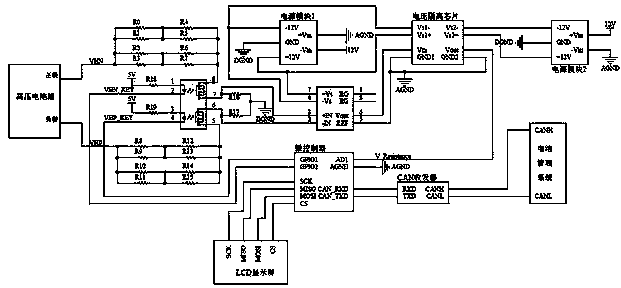

[0036] Such as figure 2As shown: the positive insulation switch circuit is mainly composed of a positive voltage divider circuit and a positive insulation optocoupler relay. When the control terminal VHP_KEY of the positive insulation optocoupler relay outputs a low level, a path is formed between pin 1 and pin 2 of the relay, so that pin 7 and pin 8 of the relay are turned on, and resistors R0~R7 and R16 form a positive voltage divider circuit. Pin 7 outputs a positive insulation resistance sampling voltage value.

[0037] The negative pole insulation switch circuit is mainly composed of a negative pole voltage divider circuit and a negative pole insulation optocoupler relay. When the control terminal VHN_KEY of the negative insulation optocoupler relay outputs a low level, a path is formed between pin 3 and pin 4 of the relay, so that pin 5 and pin 6 of the relay are turned on, and resistors R8~R15 and R17 form a negative voltage divider circuit. Pin 6 outputs a negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com