Negative pressure scraping device for photosensitive curing forming machine

A molding machine and negative pressure technology, which is applied in the field of light-curing rapid prototyping machines, can solve the problems of reduced production efficiency, long auxiliary working time, and reduced success rate of parts, so as to reduce equipment operating costs, short auxiliary working time, and achieve successful production. rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

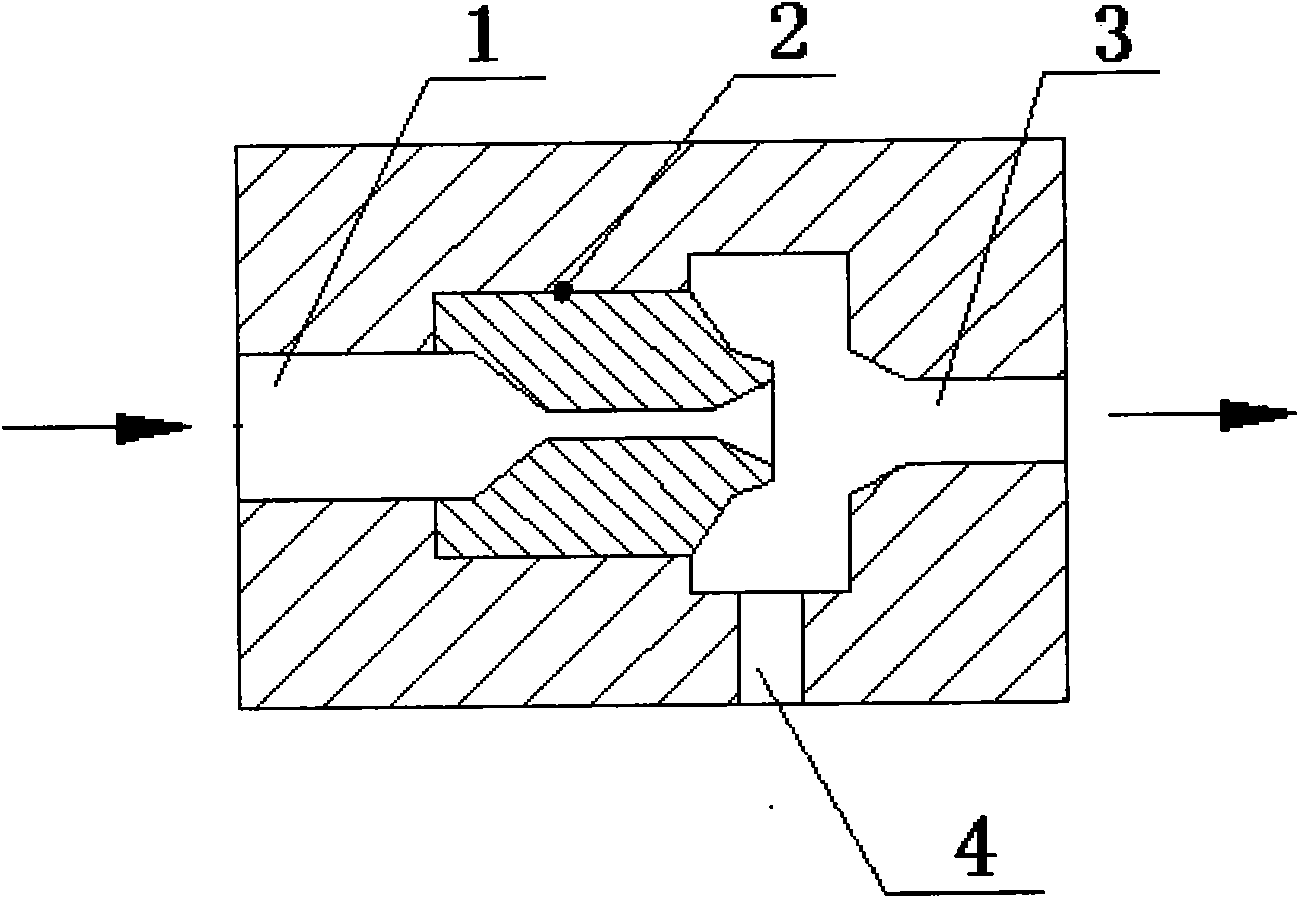

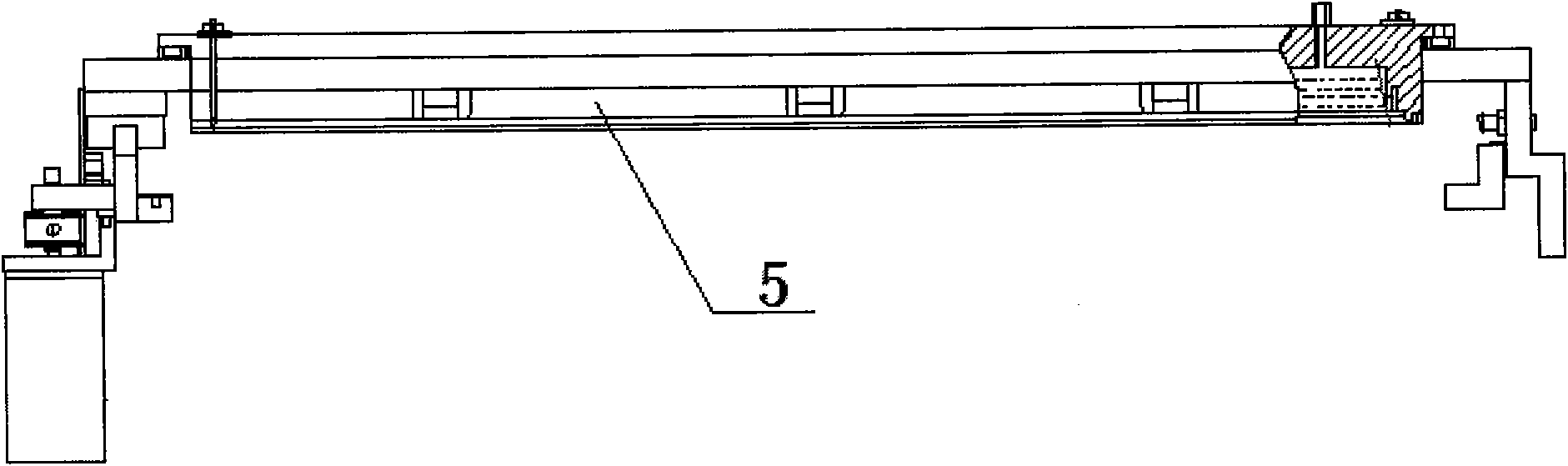

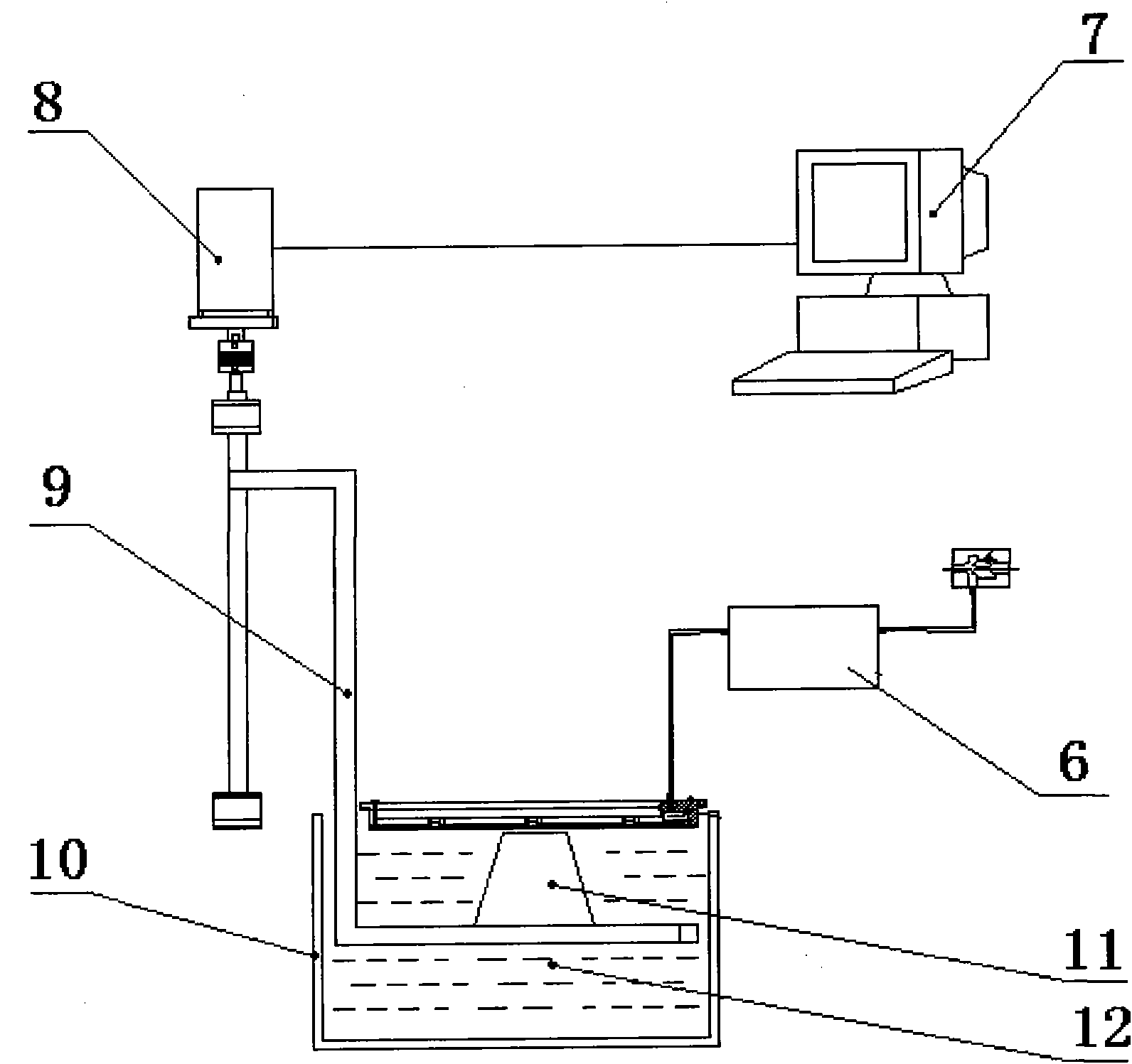

[0030] Figure 1-2 It is a schematic diagram of an embodiment of the present invention. It can be seen from the figure that the negative pressure leveling device of the photosensitive curing molding machine includes a positive pressure air source, negative pressure equipment, and a leveler. The leveler has a cavity 5, and the negative pressure equipment includes Intake pipe 1, nozzle 2, air outlet pipe 3, air suction pipe 4, the air inlet pipe 1, nozzle 2, air outlet pipe 3 are connected in sequence, one end of air suction pipe 4 is vertically connected with air outlet pipe 3, and the other end is connected with cavity 5 The positive pressure air source is connected to the intake pipe 1 . The positive pressure air source is a small air compressor, which reduces equipment operating costs.

[0031] When the device is working, negative pressure will be generated in the cavity 5 to absorb a certain amount of photosensitive resin, and the photosensitive resin stored in the cavity ...

Embodiment 2

[0038] The negative pressure scraping device of the photosensitive curing molding machine includes a positive pressure air source, negative pressure equipment, and a scraper, and the scraper has a cavity 5,

[0039] The negative pressure equipment includes an air inlet pipe 1, a nozzle 2, an air outlet pipe 3, and an air suction pipe 4. The air inlet pipe 1, the nozzle 2, and the air outlet pipe 3 are connected in sequence, and one end of the air suction pipe 4 is vertically connected with the air outlet pipe 3. The other end is connected with the cavity 5 , and the positive pressure air source is connected with the air intake pipe 1 .

[0040] When the device is working, negative pressure will be generated in the cavity 5 to absorb a certain amount of photosensitive resin, and the photosensitive resin stored in the cavity 5 will be used to supplement the recessed part, which can effectively improve the effect of photosensitive curing and recoating. There is a distance of 0.2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com