Swing testing machine for metal hose

A metal hose and testing machine technology, which is applied in the direction of testing the strength of materials by applying a stable bending force, can solve the problems of not being able to adapt to special testing machines, and achieve the effect of high-precision control of displacement and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

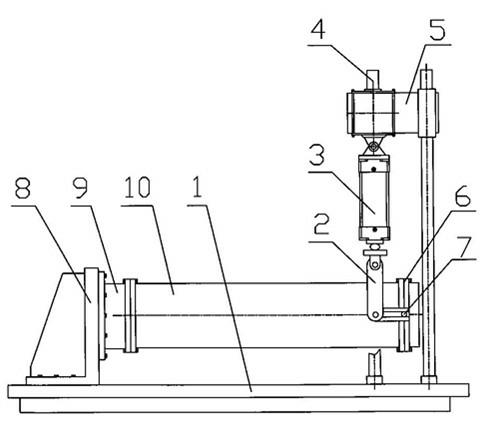

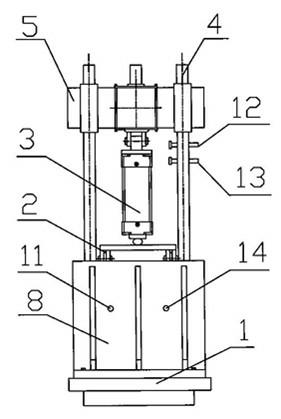

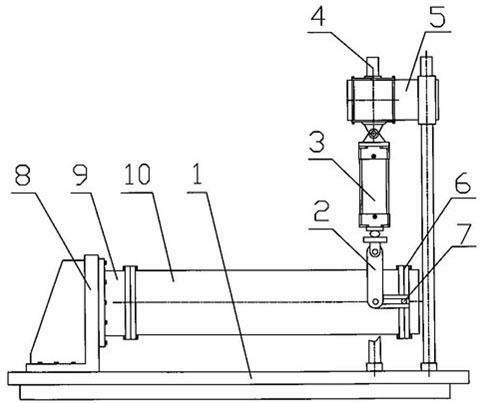

[0018] Such as figure 1 , figure 2 As shown, the main structure of the present invention includes a bottom platform 1 with a chute, a reaction force support 8 that can move on the bottom platform along the chute, and a triangular shape that is fixed on the bottom platform at the swing end side of the metal hose test piece. Three columns 4 are distributed, and the reaction support 8 is connected to the fixed end of the metal hose test piece 10. The fixed end of the metal hose test piece 10 is sealed by the fixed end tooling flange 9. A beam 5 is arranged on the upper part of the three columns, and the middle part of the beam is hinged The servo cylinder 3 with built-in displacement sensor is connected to the hydraulic air-cooled pump station with a temperature sensor. The lower part of the servo cylinder is also connected to the swing end of the metal hose test piece 10 through the connection fixture 2. The swing end is sealed by the swing end tooling flange 6; the displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com