Pipeline connection device for preventing sludge

An access device and pipeline technology, which is applied to indoor sanitary pipeline devices, water supply devices, buildings, etc., can solve the problems of occupying indoor space, unsatisfactory, leakage, etc., and achieve the effects of reliable performance, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

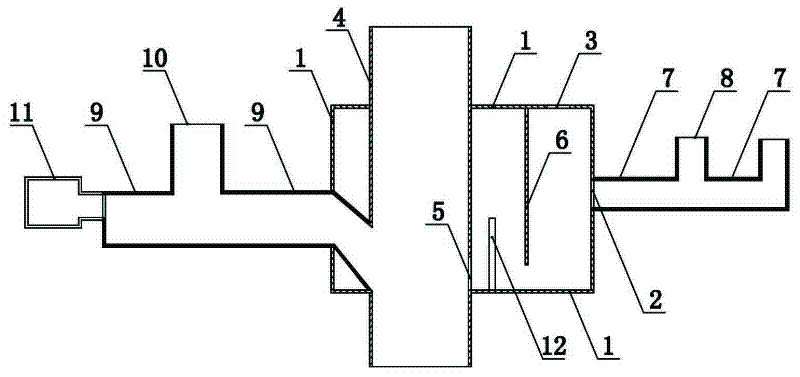

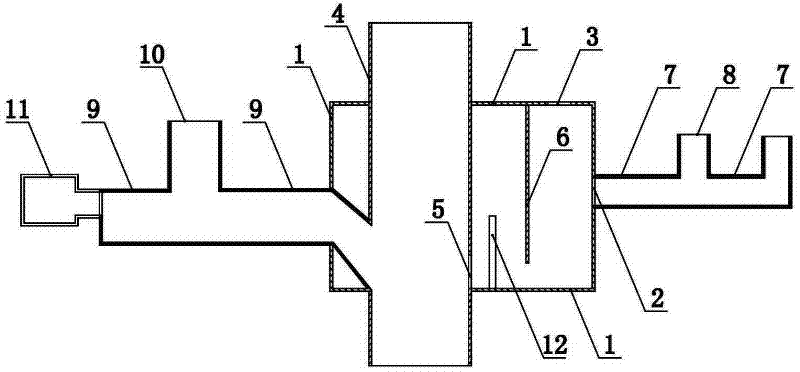

[0020] Such as figure 1 Shown, a kind of anti-silt pipeline access device, it comprises standpipe connecting pipe 4, has the sewage discharge pipe 9 of water-sealed sewage discharge inlet 10, has the waste water discharge pipe 7 of waste water discharge inlet 8, air pressure regulating box 11, The water-sealed box 1 and the water-sealed split hanging plate 6 arranged in the water-sealed box 1, wherein, the top and both sides of the water-sealed split hanging plate 6 are respectively sealed and connected to the inside of the water-sealed box 1 wall, so The standpipe connection pipe 4 is arranged through the water seal box 1, and the standpipe connection pipe 4 is provided with a drain outlet 5; the drain outlet 5 is located in the water seal box 1, and the water seal box 1 The wall of the tank is provided with a water inlet 2, and the water outlet 5 and the water inlet 2 are respectively arranged on both sides of the water-sealed partition hanging plate 6; the bottom of the wat...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that one end of the sewage drainage pipe passes through the top wall of the water-sealed tank and communicates with the riser connecting pipe, so as to adapt to different drainage methods or structures.

Embodiment 3

[0027] The main difference between this embodiment and Embodiment 1 is that the sewage drainage pipe is arranged above the water-sealed box, that is, one end of the sewage drainage pipe is directly connected with the riser connecting pipe, so as to adapt to different drainage methods or drainage structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com