Riser connecting member for draining at same layer

A technology of same-layer drainage and connecting parts, which is applied in the direction of drainage structures, waterway systems, water supply devices, etc., can solve problems such as inability to drain and clear, unsightly, inconvenient decoration, etc., to avoid the hidden danger of water accumulation and leakage, and avoid indoor The effect of back odor and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

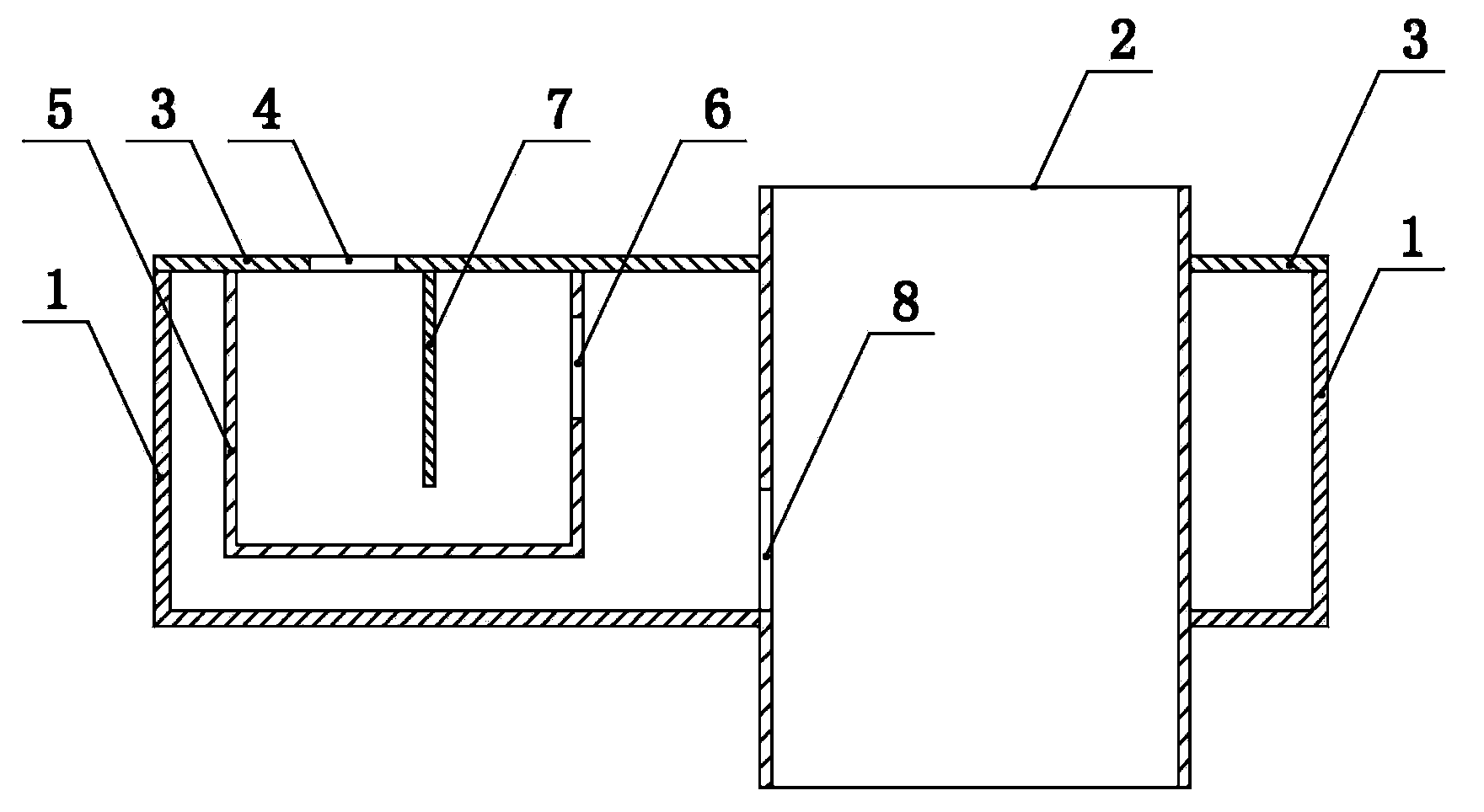

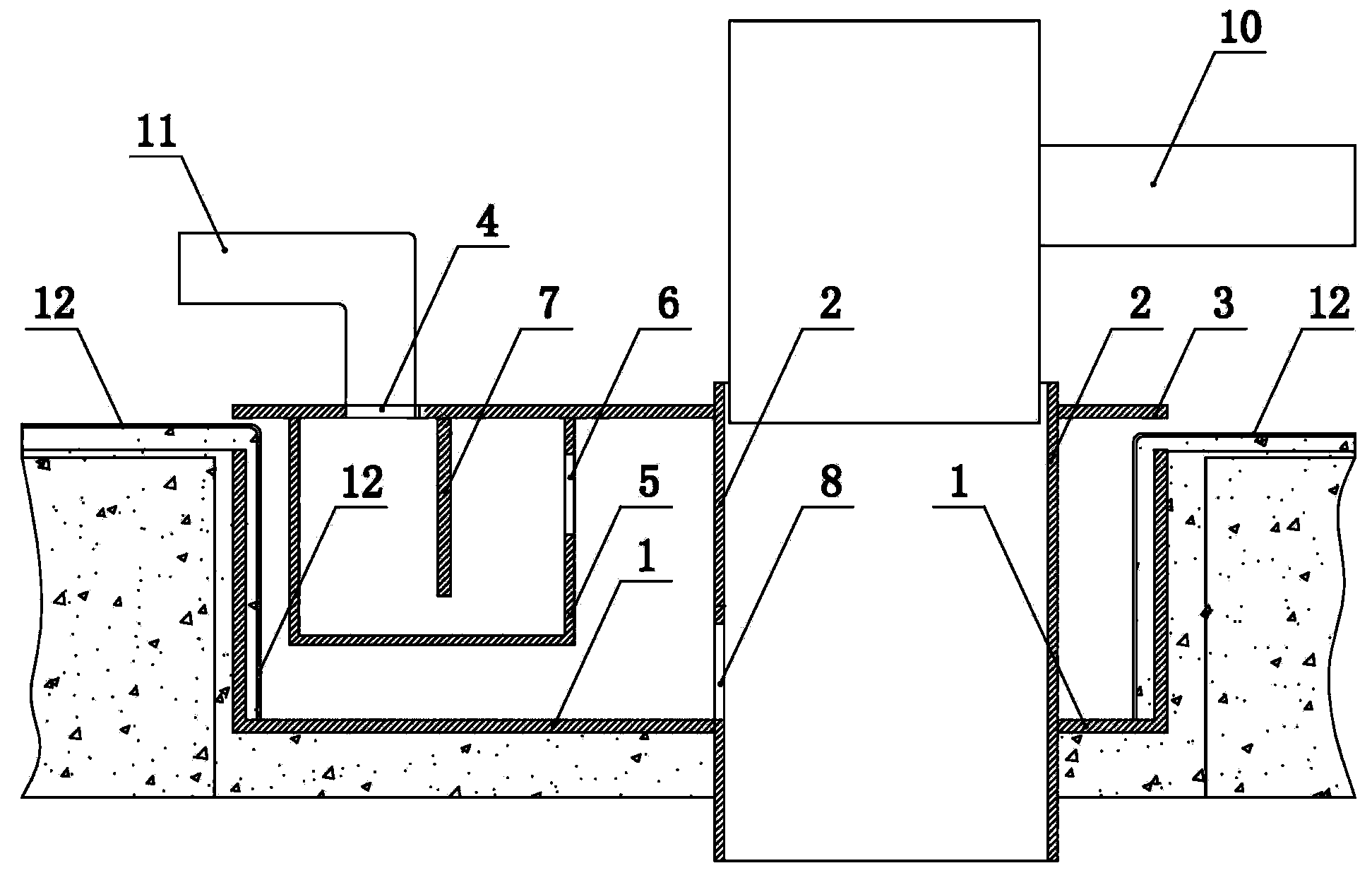

[0023] Such as figure 1 with figure 2 As shown, a same-layer drainage standpipe connector, which includes a water collection box 1, a riser connecting pipe 2 set through the water collection box 1, a top cover 3 constituting the top of the water collection box 1 and a water tank installed in the water collection box 1 Sealing device, wherein the water sealing device includes a water sealing box 5, a box body water sealing partition 7 arranged in the water sealing box 5, and a water inlet arranged on the wall of the water sealing box 5 4 and drain 6; the water seal box 5 is arranged on the lower end surface of the top cover 3, that is, the part of the top cover 3 constitutes the top wall of the water seal box 5, and the top cover 3 is provided with Drainage inlet, the drainage inlet is the water inlet 4, the top and both sides of the water-sealed partition plate 7 of the box are respectively sealed and connected with the box wall of the water-sealed box 5, and the water-seale...

Embodiment 2

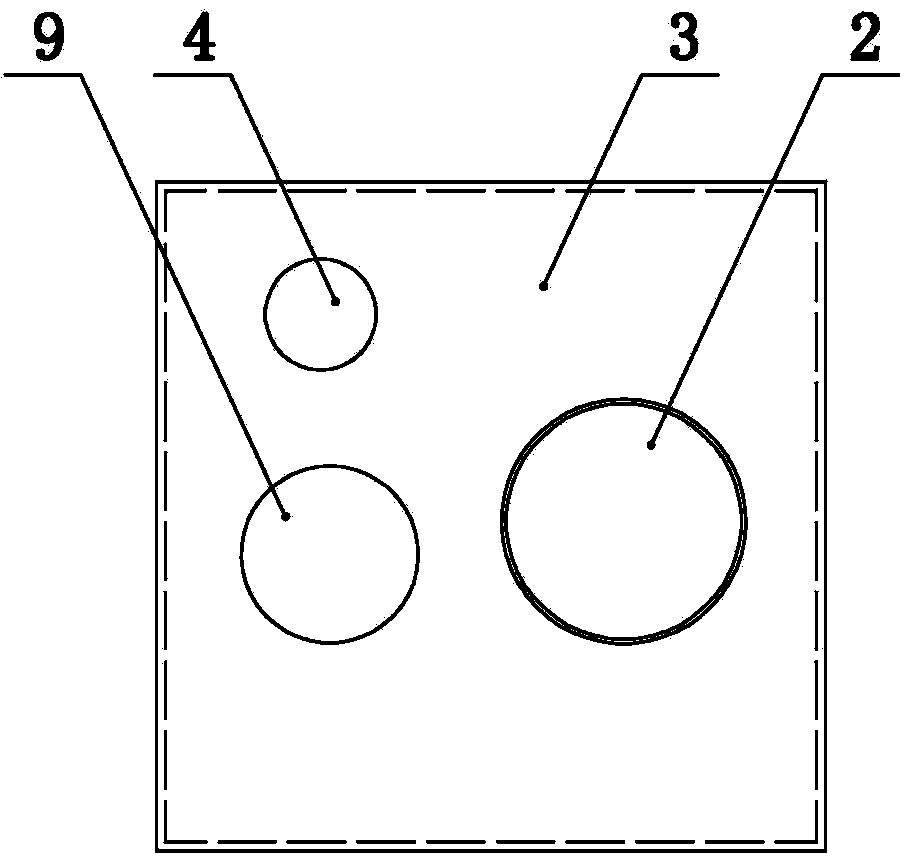

[0028] The difference between this embodiment and embodiment 1 mainly lies in: as Figure 4 As shown, the water sealing device includes a water sealing box 5, a water sealing cylinder 7 arranged in the water sealing box 5, a water inlet 4 and a water outlet 6 arranged on the wall of the water sealing box 5, so The top cover 3 constitutes the top tank wall of the water seal box 5, the top of the water seal tube 7 is arranged on the top tank wall of the water seal box 5, and the bottom end of the water seal tube 7 is higher than the water seal box 5, the water inlet 4 is set corresponding to the top inlet of the water seal cylinder 7, and the lowest point of the drain port 6 is not lower than the bottom outlet of the water seal cylinder 7.

Embodiment 3

[0030] The main difference between this embodiment and embodiment 1 is that the water sealing device is a U-shaped water sealing tube or an S-shaped water sealing tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com