Spring clamp element and terminal

A spring clip and component technology, applied in the field of spring clip components, can solve the problems of increasing the structure height, bulkiness, large space, etc., and achieve the effect of reducing the structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

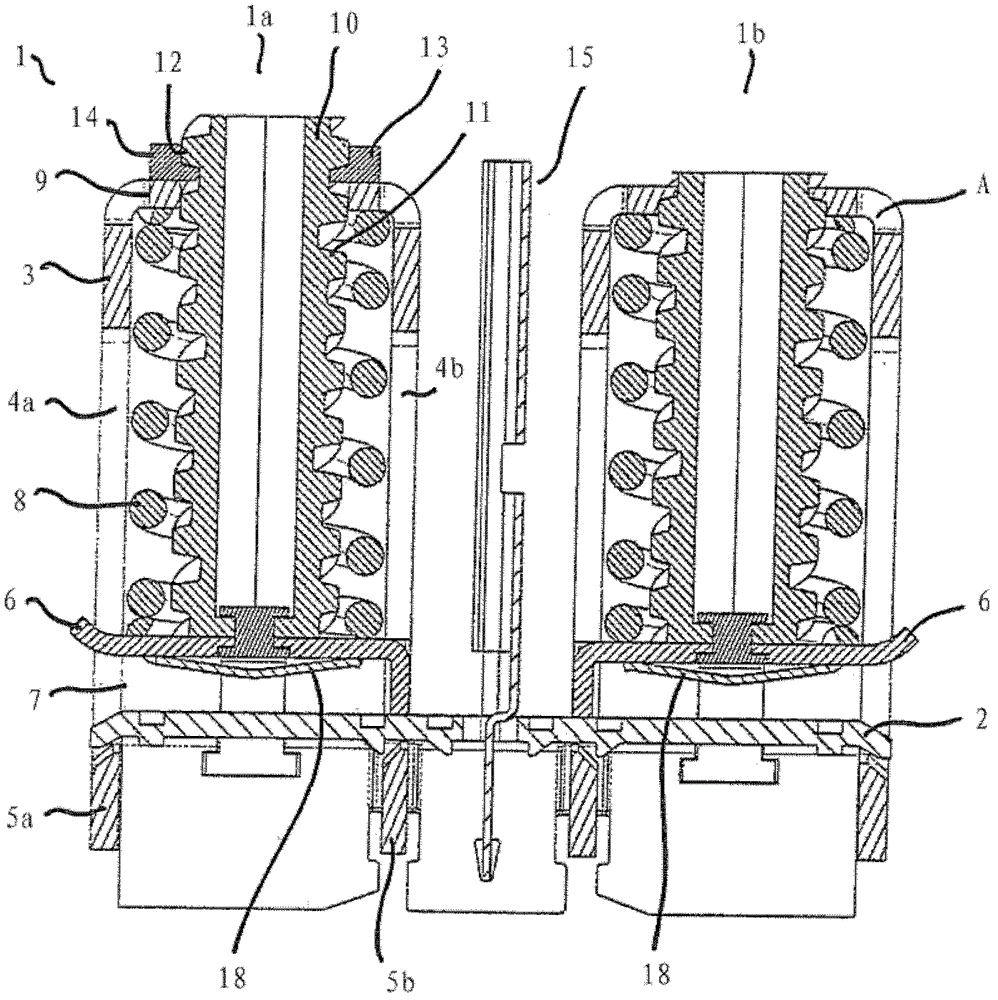

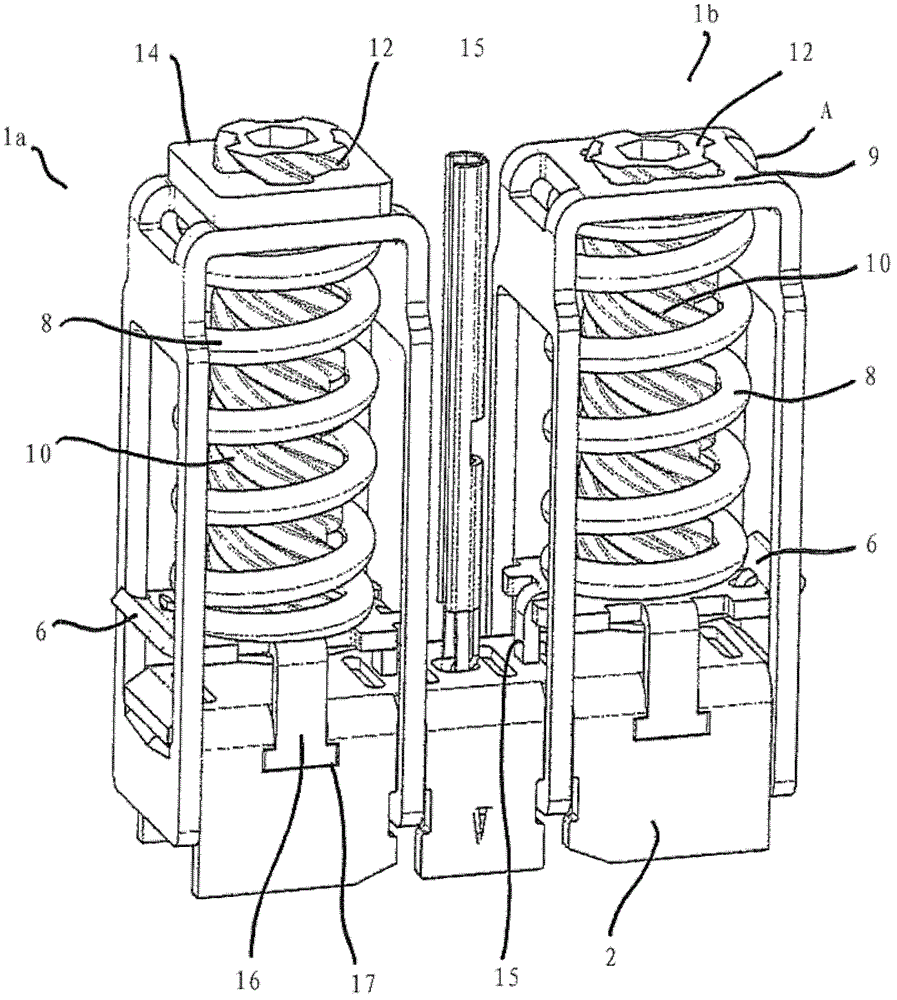

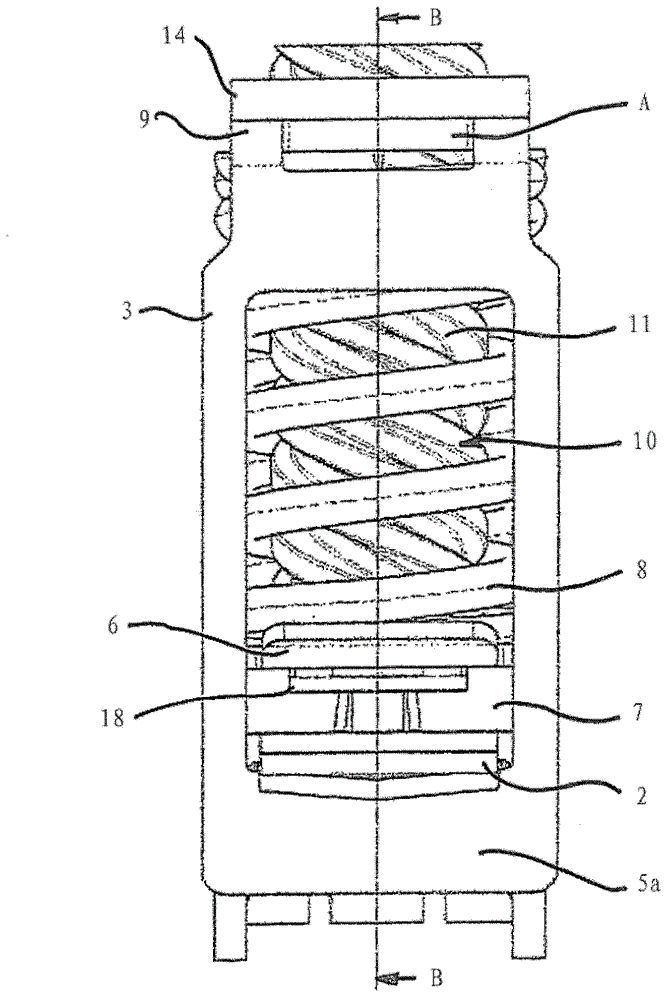

[0042] Depend on figure 1 A first embodiment of the spring clip element 1 can be seen. In the exemplary embodiment shown, two spring clip elements 1 a , 1 b are realized on a common busbar part 2 .

[0043] The spring clip elements 1a, 1b each utilize a section of the busbar part 2 in which the tensioning bar 3 is displaceably mounted. For this purpose, the tensioning strip 3 has, for example, on its opposite side walls openings 4 a , 4 b through which the busbar 2 passes. The openings 4 a , 4 b are each delimited by a clamping edge 5 a , 5 b arranged below the busbar 2 .

[0044] In this exemplary embodiment, the busbar part 2 has a tunnel plate 6 which, starting from the busbar part 2 , is bent into a section extending parallel to the busbar part 2 , so that a tunnel between the busbar part 2 and the tunnel plate 6 is formed. The connecting cavity 7 between the inner walls. Arranged above the tunnel plate 6 is a helical spring 8 in the form of a helical compression sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com