Device and method for preventing rotary mechanism from automatically rotating

A slewing mechanism and automatic rotation technology, applied in the direction of cranes, etc., can solve the problems of difficulty in installing workpieces, safety accidents, and difficulty in installing and positioning of hoisted objects, and achieve the effect of improving convenience and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

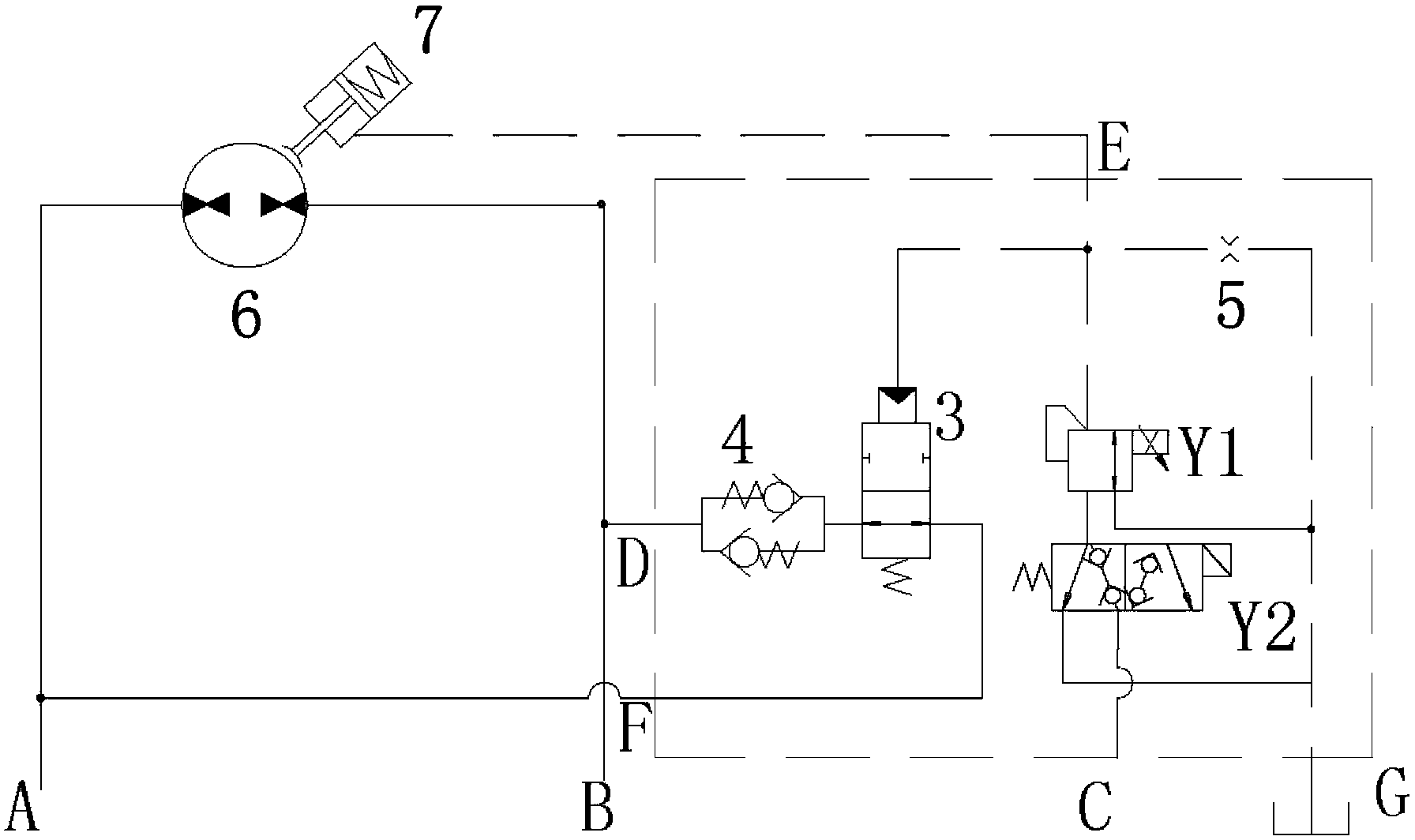

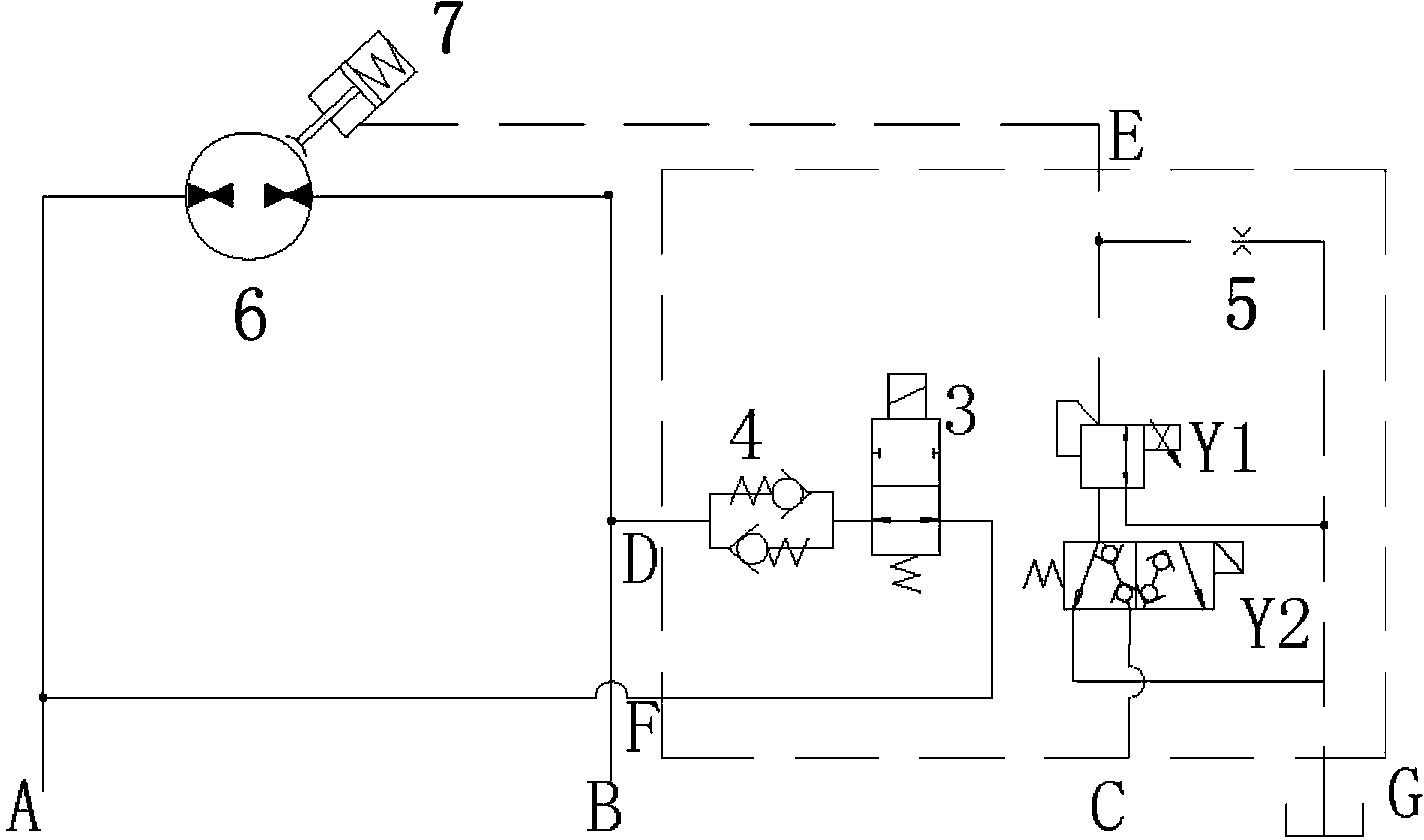

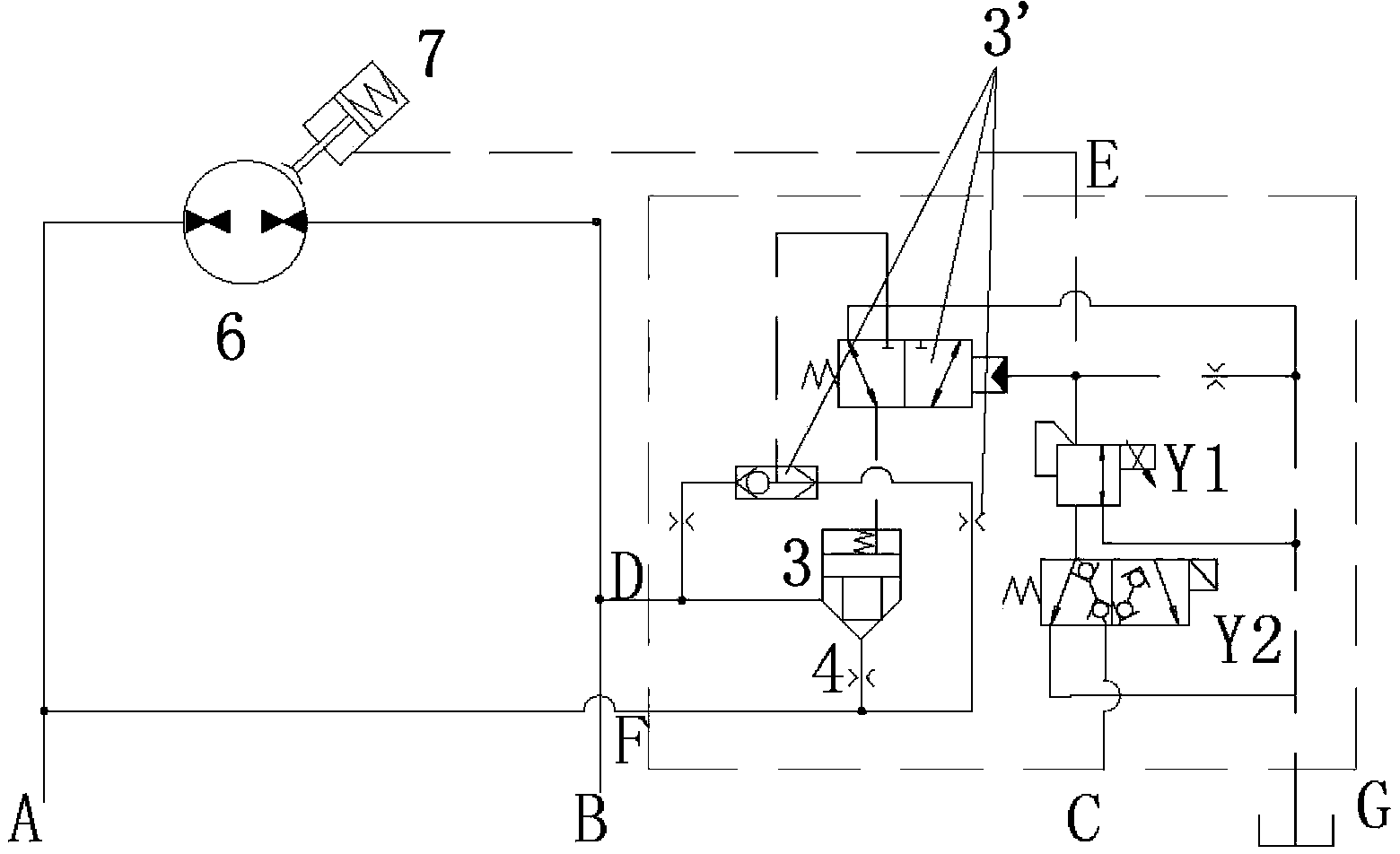

[0046] figure 1It shows the device and its hydraulic principle for preventing the automatic rotation of the slewing mechanism of the crane according to the present invention. The slewing mechanism of the crane usually includes a slewing handle, an oil tank, a slewing brake 7 and a slewing motor 6, etc. The components of the device are connected in a known manner to form an oil circuit (for example, the oil circuit of a slewing mechanism in existing cranes). According to this principle, the device to prevent the automatic rotation of the slewing mechanism of the crane includes the electric proportional pressure reducing valve Y1, the switch valve Y2 and the first hydraulic control part 3, etc., and the electric proportional pressure reducing valve Y1 set in the device is used to realize the control The opening time of the slewing brake 7 prevents the slewing mechanism from automatically rotating. The specific working principle is as follows:

[0047] The device for preventing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com