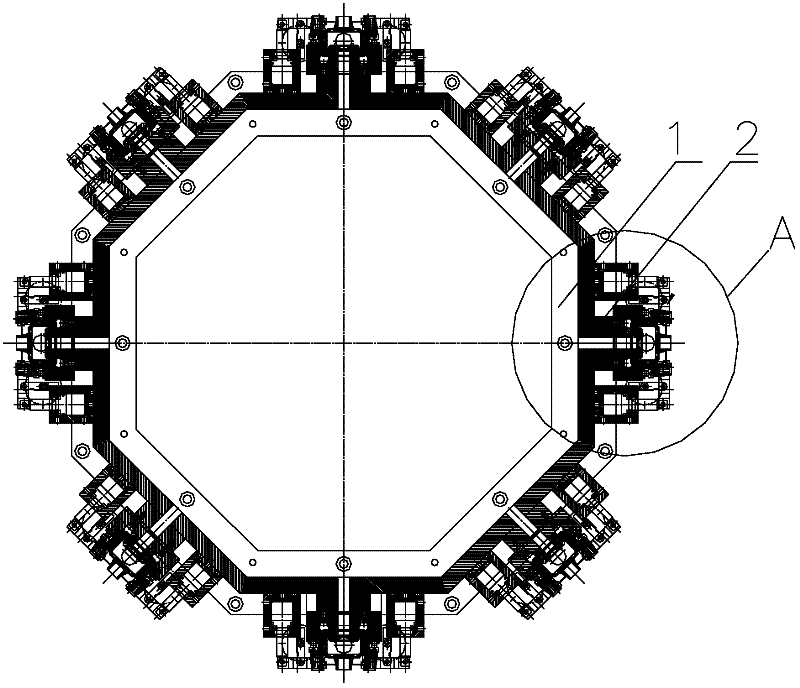

Octahedron clamping device

A clamping device and octahedron technology, applied in the field of mechanical processing, can solve problems such as not easy to ensure product size, large physical expenditure of operators, unfavorable mass production, etc., to shorten clamping time, reduce labor intensity, and improve product quality. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

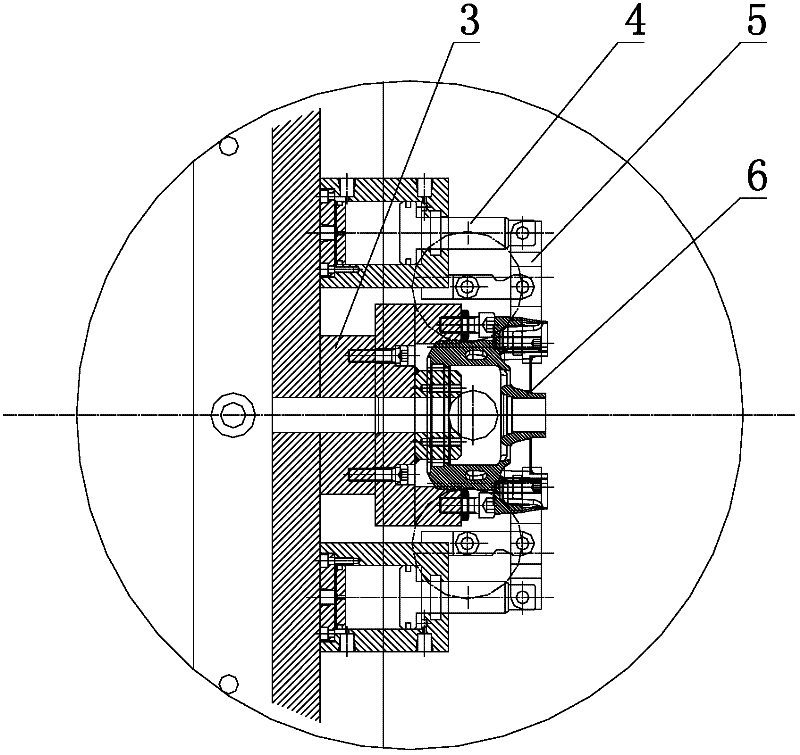

[0014] An octahedron clamping device, which is composed of a mounting base 1 and a clamp unit 2, the mounting base is a regular octagonal mounting base, each side of the regular octagonal mounting base is respectively equipped with clamping units, and the clamping units are composed of clamping units The main body 3, the hydraulic cylinder 4 and the pressure plate 5 are composed. The main body of the fixture is fixed on the outer surface of each side of the regular octagonal mounting seat. The hydraulic cylinders are symmetrically installed on both sides of the main body of the fixture, and the pressure plates are respectively fixed on the top of the cylinder rod of the hydraulic cylinder. , to fasten the workpiece.

[0015] During operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com