Direct push type safety chuck

A safety chuck and shaft technology, applied in the field of direct-push safety chucks, can solve problems such as difficult operation, poor safety, and complex structure of safety chucks, and achieve the effects of ensuring safety and reliability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

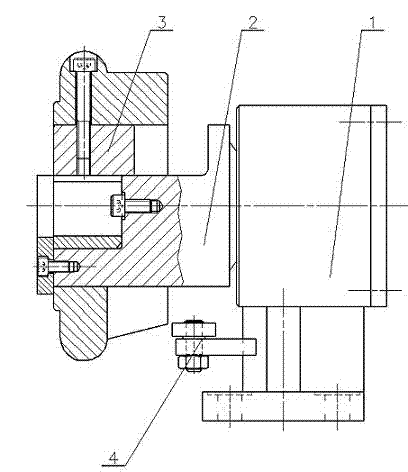

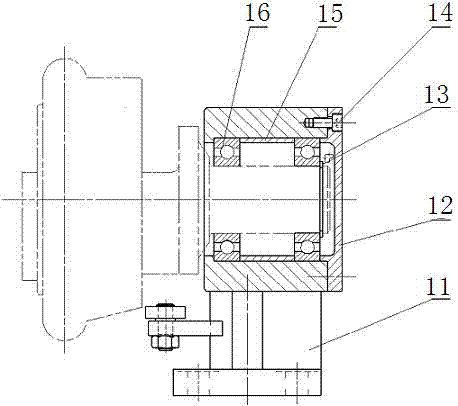

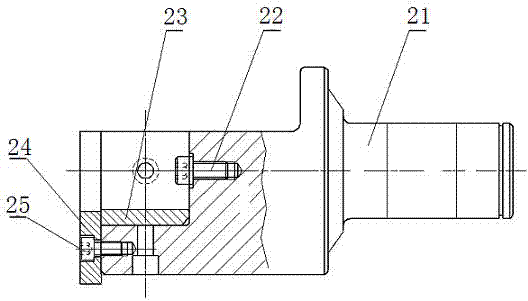

[0020] Such as Figure 1-Figure 8 As shown, the direct push type safety chuck consists of a supporting part 1, a shaft part 2, a sliding part 3 and a locking part 4. The supporting part 1 is connected to the shaft part 2, the sliding part 3 is connected to the shaft part 2, and the locking part 4 is connected to the support part 1. The support part 1 includes a support 11, an end cover 12, a retaining ring 13, a positioning sleeve 15 and a bearing 16. The end cover 12 is fixed on the support 11 by a screw 14, and the bearing 16 is arranged on the rotating shaft. The positioning sleeve 15 is installed between the bearings 16 and the retaining ring 13 is arranged at the front end of the bearing 16. The rotating shaft part 2 includes a rotating shaft 21, a liner 23 and a baffle 24. The liner 23 is connected to the three sides of the shaft 21 and the baffle 24 The end surface of the rotating shaft 21 is connected by a screw 25. A screw 22 is provided at the center of the rotating s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap