Screw, rocking block guide rod and trough-type cam combined space mechanism of sliding plug door

A technology that combines space and groove shape, applied in the direction of power control mechanism, wing control mechanism, door device, etc., can solve the problems of affecting the dynamic stability of the door leaf, occupying a large space, poor stability of the main shaft, etc., and achieve good dynamic stability. resistance, small friction and wear, and the effect of improving load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

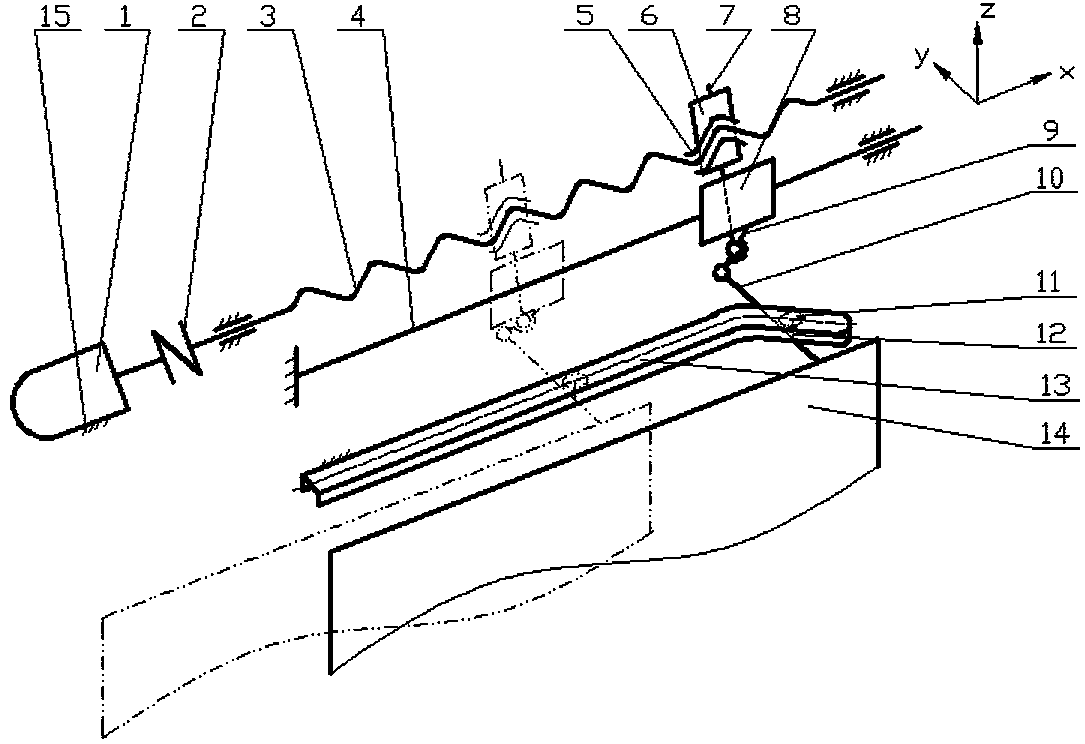

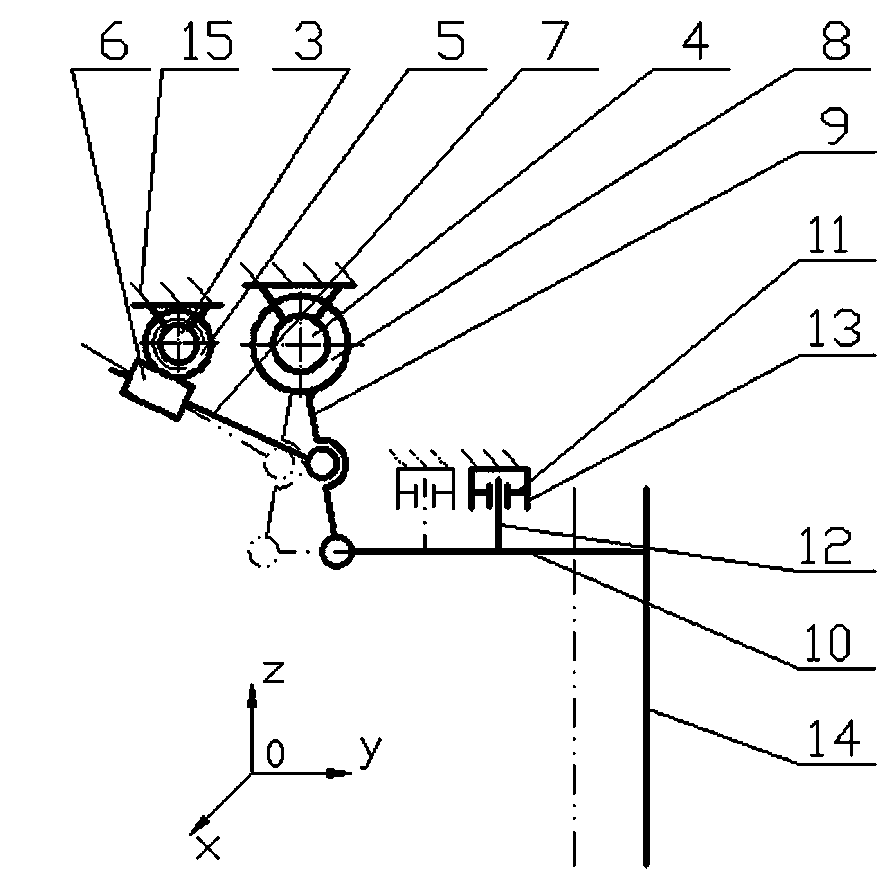

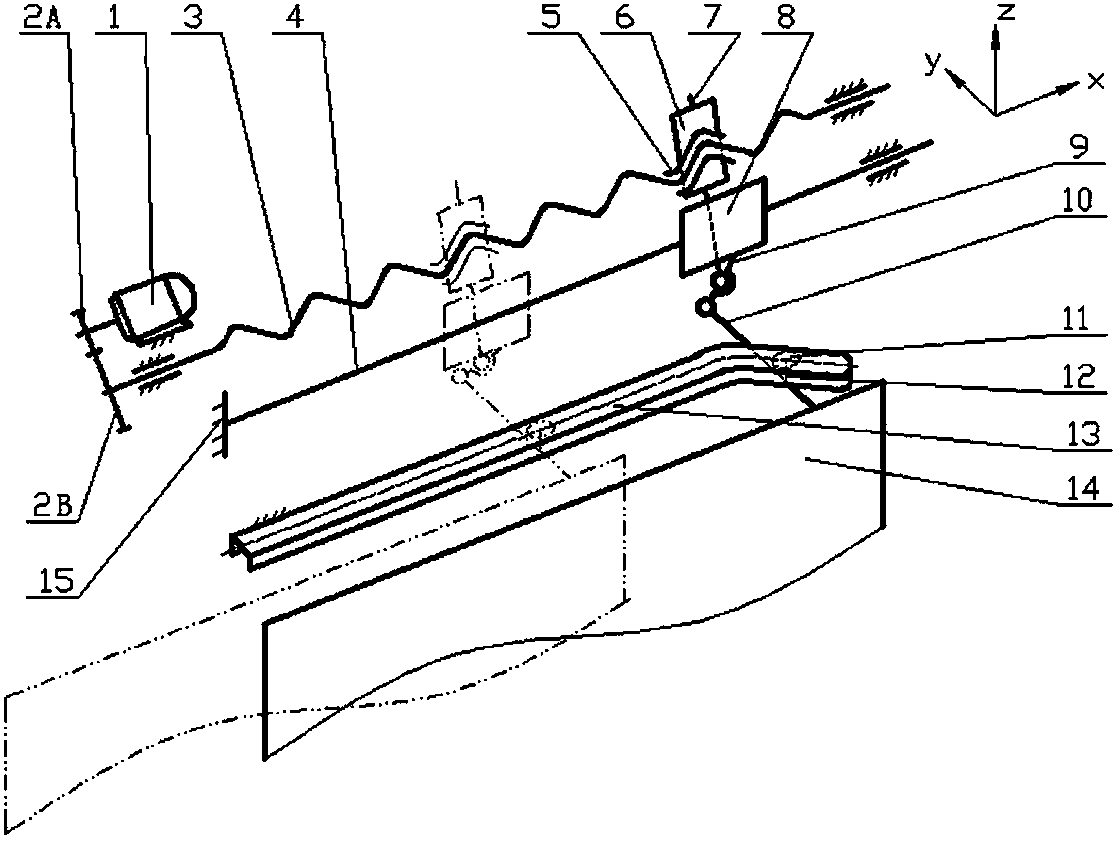

[0025] Refer to attached Figure 1~4 , a sliding door spiral rocker guide rod grooved cam combination space mechanism of the present invention includes a motor 1, a coupling 2, a screw rod 3, a bearing shaft 4, a nut 5, a rocker 6, a guide rod 7, a bushing 8, Rocker 9, door handle 10, roller 11, roller shaft 12, grooved cam 13, door leaf 14, door frame 15, etc., wherein screw rod 3 and nut 5 form a screw mechanism; rocker 6, guide rod 7, rocker Rod 9, bearing shaft 4, and shaft sleeve 8 form a rocker guide rod mechanism; roller 11, roller shaft 12, grooved cam 13, door handle 10, door leaf 14, and door frame 15 form a grooved cam mechanism. The combination of mechanism, rocker guide rod mechanism and grooved cam mechanism forms a spiral rocker guide rod grooved cam combined space mechanism.

[0026] The door frame 15 is fixed with the car body, the motor 1 fixed on the door frame 15 is connected with the screw rod 3 through the coupling 2, the other end of the screw rod 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com