Motorcycle tire for running on rough terrain

A motorcycle and tire technology, applied to motorcycle tires, motorcycles, off-road vehicle tires, etc., can solve the problems of unexpectable turning performance and improvement, and achieve the effect of improving turning performance and maintaining traction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

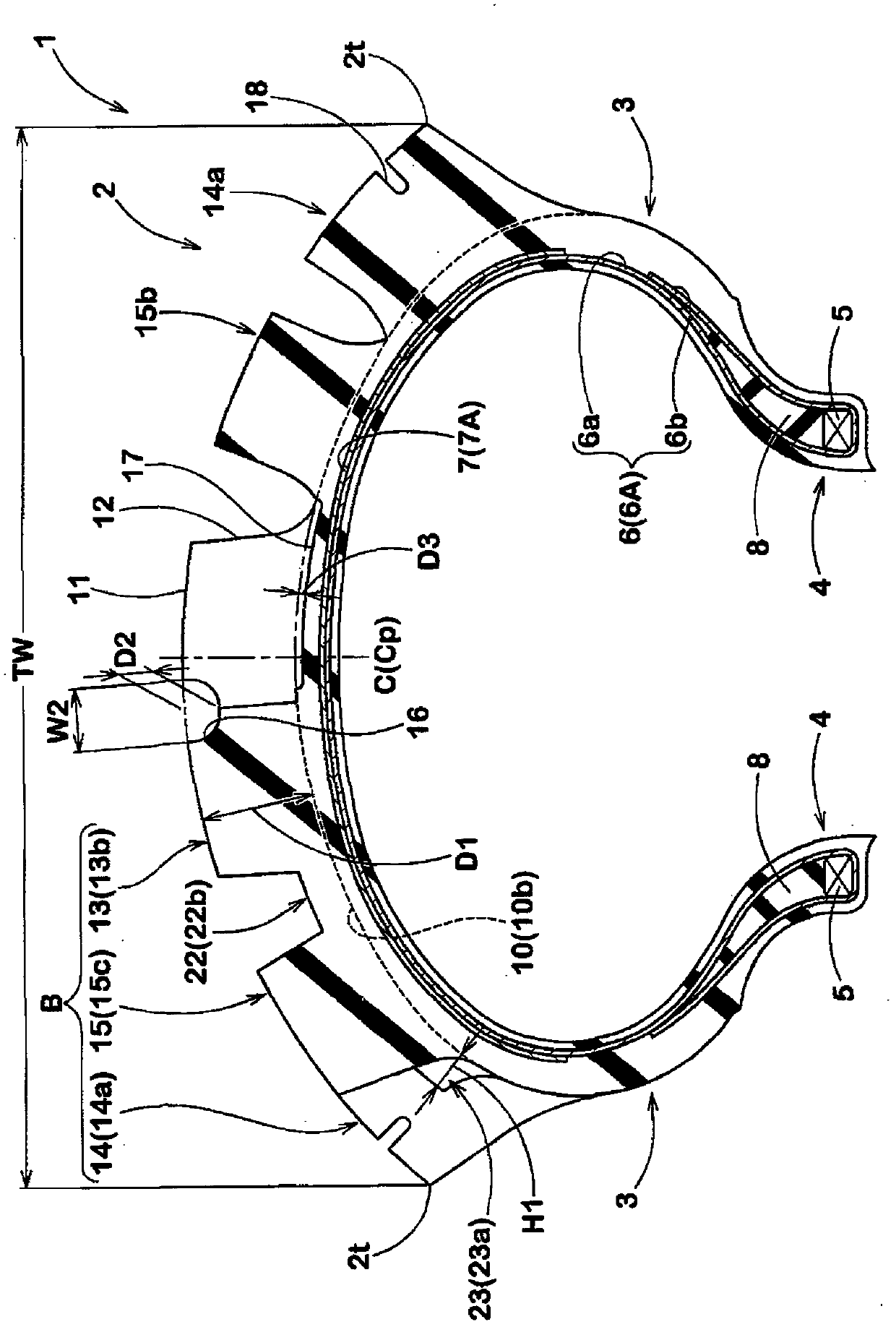

[0082] Prototype has figure 1 The basic structure shown in Table 1 and the front wheel and rear wheel of motorcycle tires for driving on uneven ground with inclined grooves shown in Table 1, and their performances were tested. In addition, the common specifications are as follows.

[0083] tire size

[0084] Front wheel: 90 / 100-21

[0085] Rear wheel: 120 / 80-19

[0086] Rim size

[0087] Front wheel: 1.60×21

[0088] Rear wheel: 2.15×19

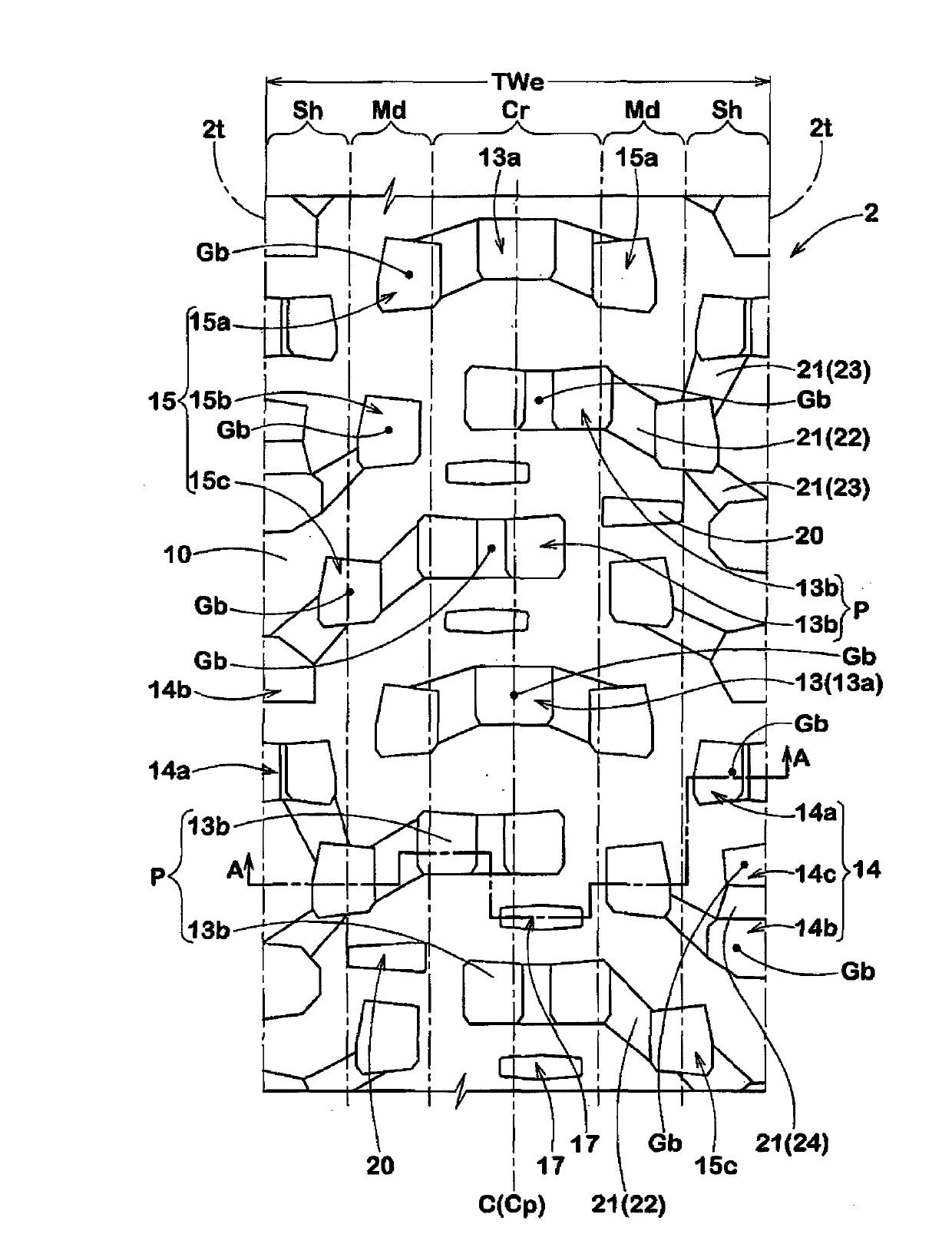

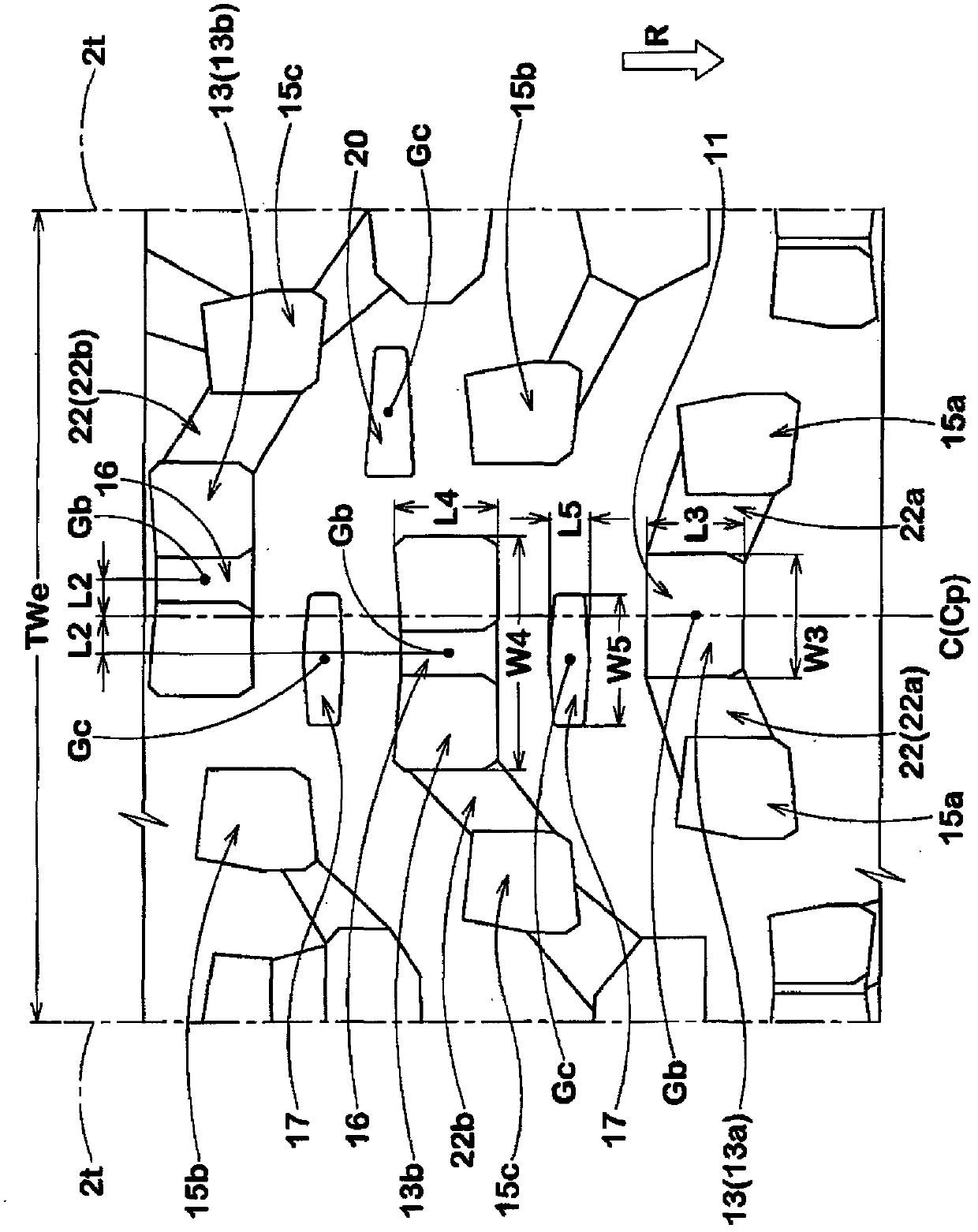

[0089] Tread width TW: 150.0mm

[0090] Tread expansion width TWe: 169.5mm

[0091] Land ratio (Sb / S): 20.5%

[0092] The maximum length L3 of the center crown block in the tire circumferential direction: 20.0mm

[0093] The maximum length L4 of the side crown block in the tire circumferential direction: 21.5mm

[0094] Block height D1: 16.0mm

[0095] Recess, side recess:

[0096] Maximum width W5: 30.0mm

[0097] Maximum length L5: 10.0mm

[0098] Depth D3: 0.5mm

[0099] Ratio (W5 / TWe): 17.7%

[0100] Ratio (L5 / W5): 33.3% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com