Radial tire for use in two-wheeled vehicle

A radial tire and vehicle technology, applied in motorcycle tires, special tires, vehicle parts, etc., can solve the problems of increased tread temperature, insufficient use of grip, excessive tread temperature increase, etc., to reduce excessive deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

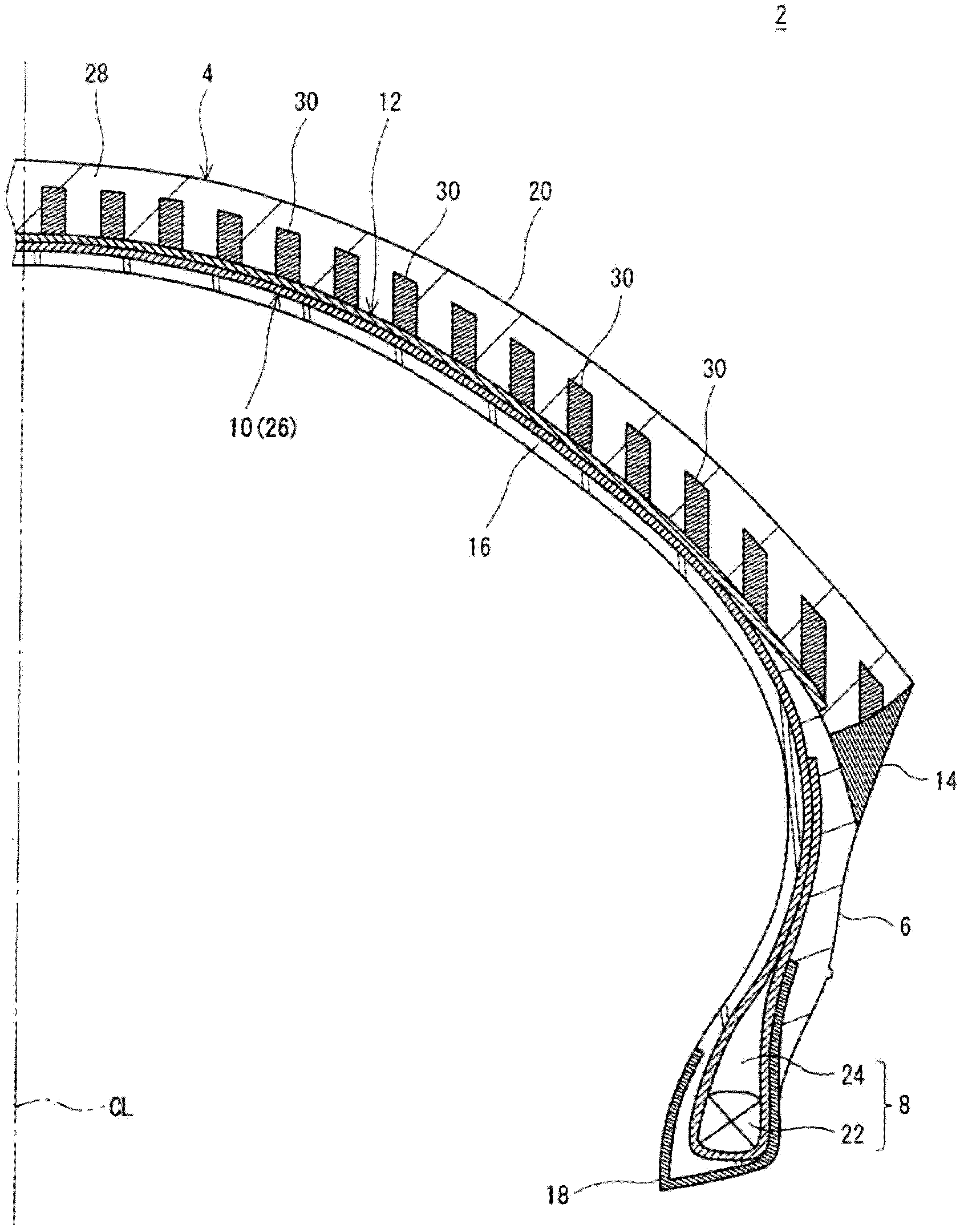

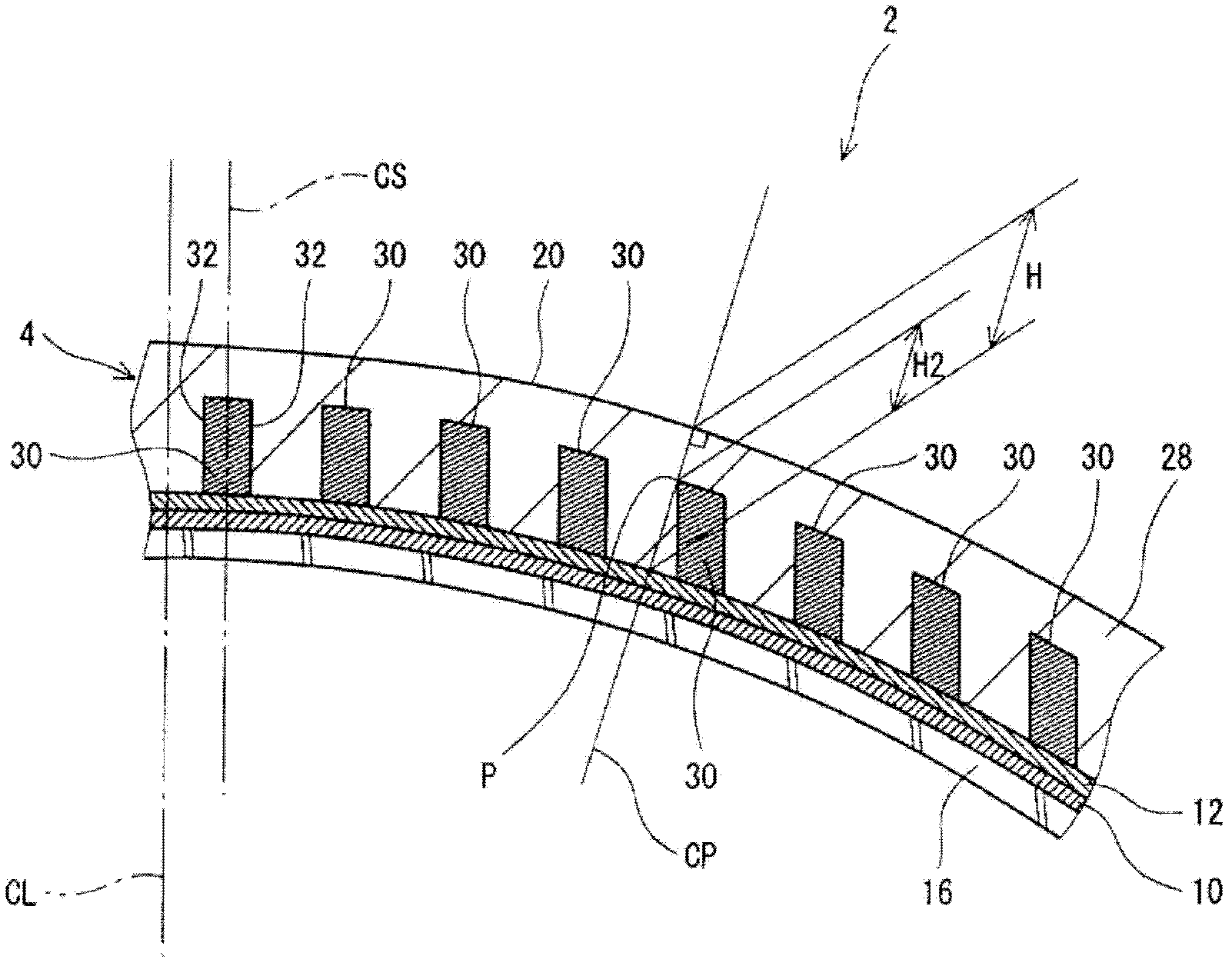

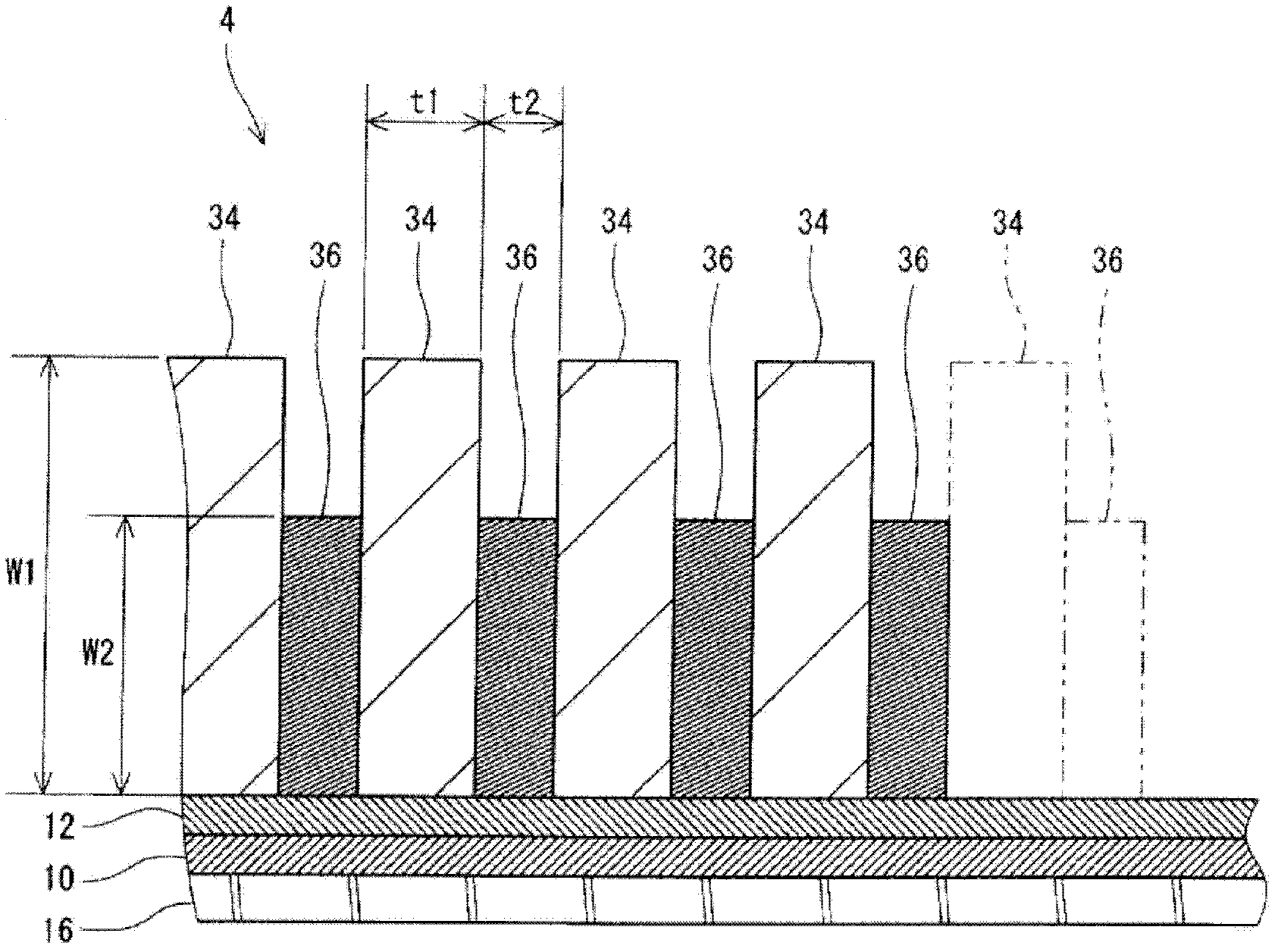

Embodiment 1

[0085] A radial tire (size: 180 / 55ZR17) for two-wheeled vehicles was obtained, having Figure 5 The basic structure shown in and a detailed description shown in Table 1 below. In the production of tires, a first strip formed of a first rubber composition to form the main body and a second strip are helically wound alternately to form the tread Formed from a second rubber composition so as to form the support portion. The thickness t1 of the first strip is 2.0 mm and the thickness t2 of the second strip is 1.5 mm. Therefore, the ratio t2 / t1 of the thickness t2 to the thickness t1 is 0.75. The tread thus formed comprises a main body and a plurality of supports arranged axially relative to each other. Each support portion is inclined axially outward and radially from the inner side toward the outer side. This state is indicated by an "X" in the cell for the tilt direction in the table. The inclination angle α of each support portion is 20 degrees. The supporting portion is ...

Embodiment 2-7

[0087] Tires were each obtained so as to have the same structure as the tire in Example 1 except that the thickness t1 and thickness t2 were different from those in Example 1, and the ratio t2 / t1 was shown in Table 1 and Table 2 below.

Embodiment 8-13 and comparative example 2

[0089] Tires were each obtained so as to have the same structure as the tire in Example 1, except that the complex elastic modulus E2* of the support portion was different from that in Example 1, and the ratios E2* / E1* were shown in Table 2 and Table 3 below middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com