Drainage pipeline hot melting installation system

A technology for installing systems and drainage pipes, which is applied in the direction of pipe connection layout, pipe/pipe joints/pipe fittings, mechanical equipment, etc. It can solve the problems of uncontrollable deformation of plastic polyethylene pipes, and achieve controllable heating range, easy connection and uniformity. heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

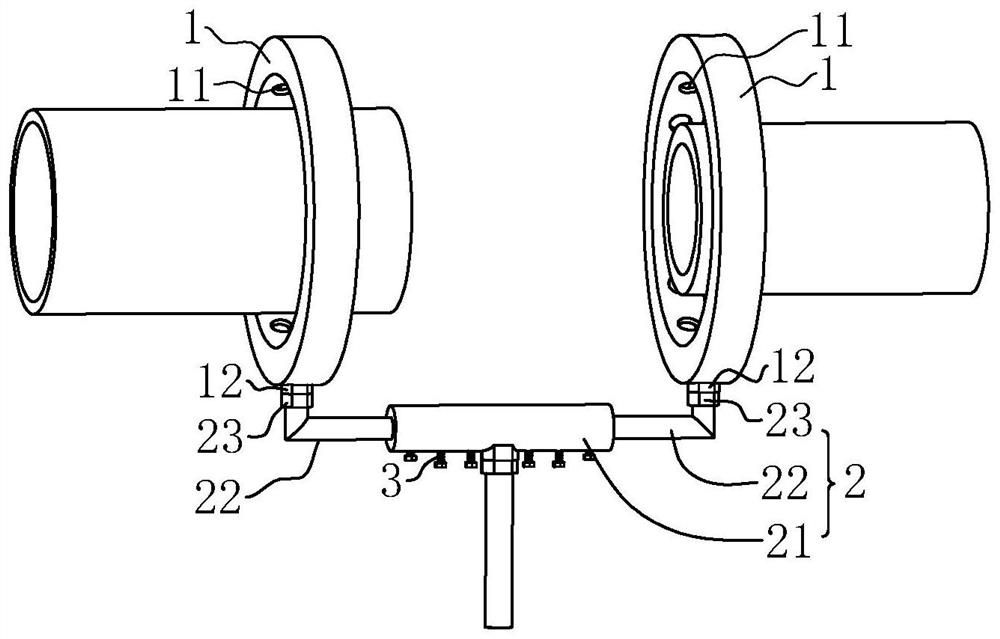

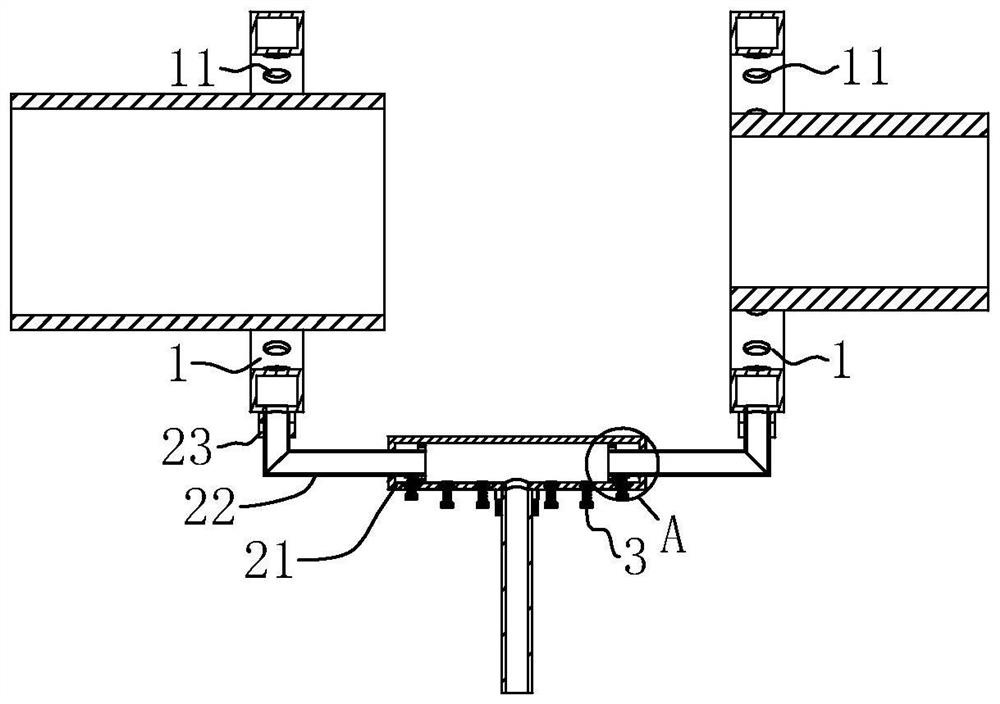

[0039] refer to figure 1 , the hot-melt installation system for drainage pipes includes two heating rings 1 for heating plastic polyethylene pipes and iron pipes respectively. It is arranged coaxially, and the distance between the two heating rings 1 along its axis is adjustable, so that when one heating ring 1 heats the fixed area of the iron pipe, the other heating ring 1 heats the heating area of the plastic polyethylene pipe. Adjustment.

[0040] In this embodiment, a rigid communication pipe 2 is connected between the two heating rings 1, and the communication pipe 2 realizes the coaxial connection between the two heating rings 1. The inner cavity is connected, and the connecting pipe 2 is connected with the gas pipeline. After the gas pipeline sends gas into the connecting pipe 2, the connecting pipe 2 sends the gas into the two heating rings 1 respectively.

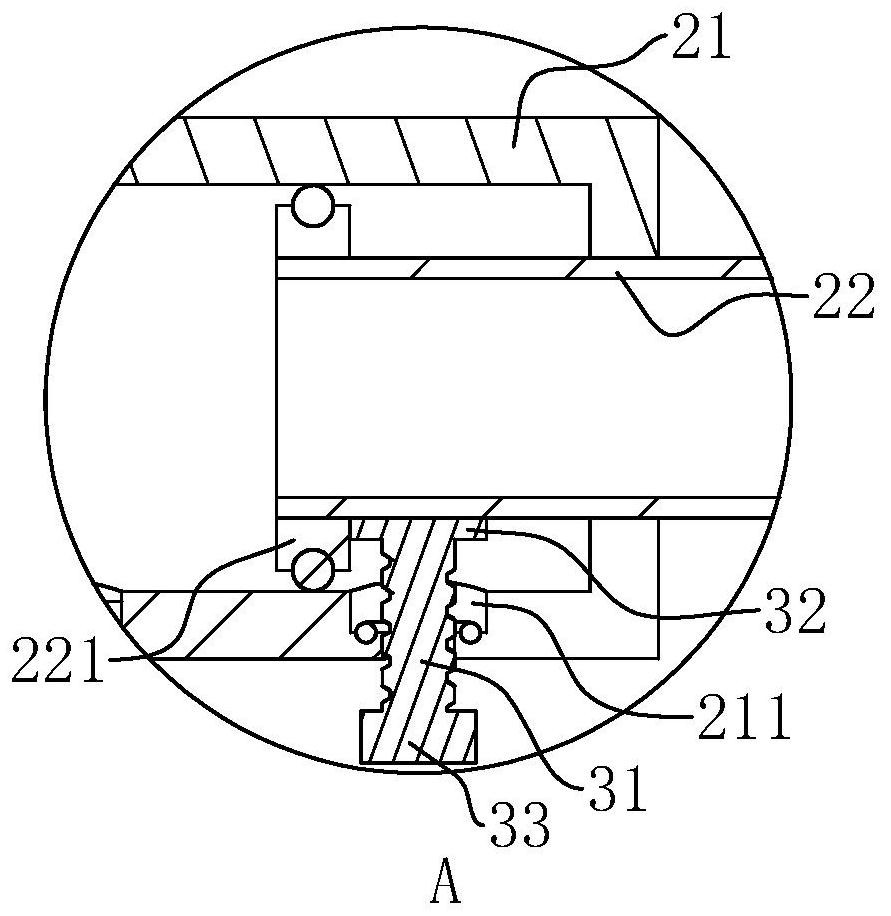

[0041] The inner cavity of the heating ring 1 is provided with a fluid channel communicating with the inne...

Embodiment 2

[0058] refer to Figure 4 , The difference between this embodiment and Embodiment 1 is that the drainage pipe hot-melt installation system includes a communication pipe 2, which is a flexible pipe, and the two ends of the communication pipe 2 are respectively connected with the two heating rings 1 through joints, and communicated with each other. Pipe 2 communicates with the gas pipeline. Between the two heating rings 1 is connected a support rod 4 connected to the heating ring 1 with adjustable length at both ends. The support rod 4 includes an inner rod and an outer rod that can slide mutually, and the inner rod and the outer rod slide mutually to realize two heating Adjustment of ring 1 axial distance.

[0059] As an optional solution, a flow regulating valve 5 is provided between the communication pipe 2 and the heating ring 1 , and in this embodiment, one flow regulating valve 5 is provided to control the amount of gas entering one of the heating rings 1 . In another em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com