Seat framework for vehicle use

A seat frame and vehicle technology, applied to vehicle seats, seat frames, vehicle components, etc., can solve the problems of reduced side frame strength and low section coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

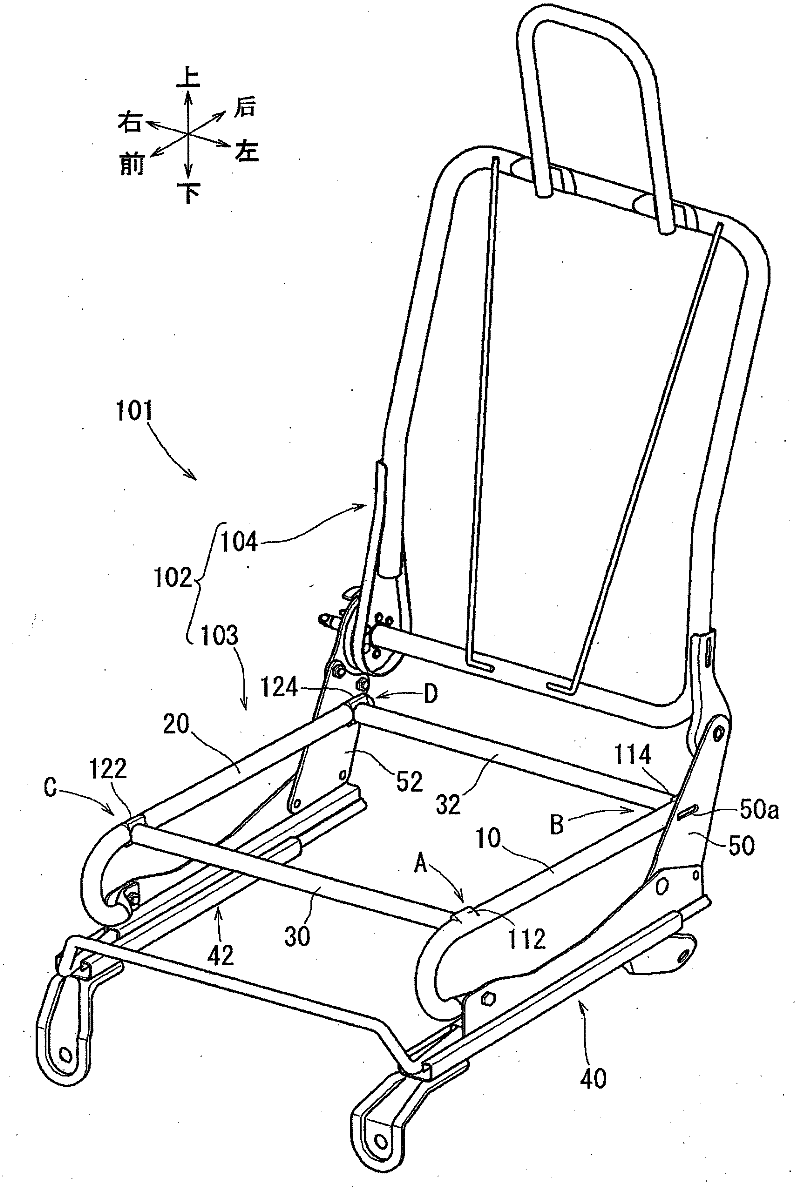

[0049] Next, refer to Figure 5-6 Embodiment 3 of the present invention will be described. This Example 3 is an aspect which can more easily assemble a seat cushion (not shown) to the seat cushion frame 203 than the Example 2 already described.

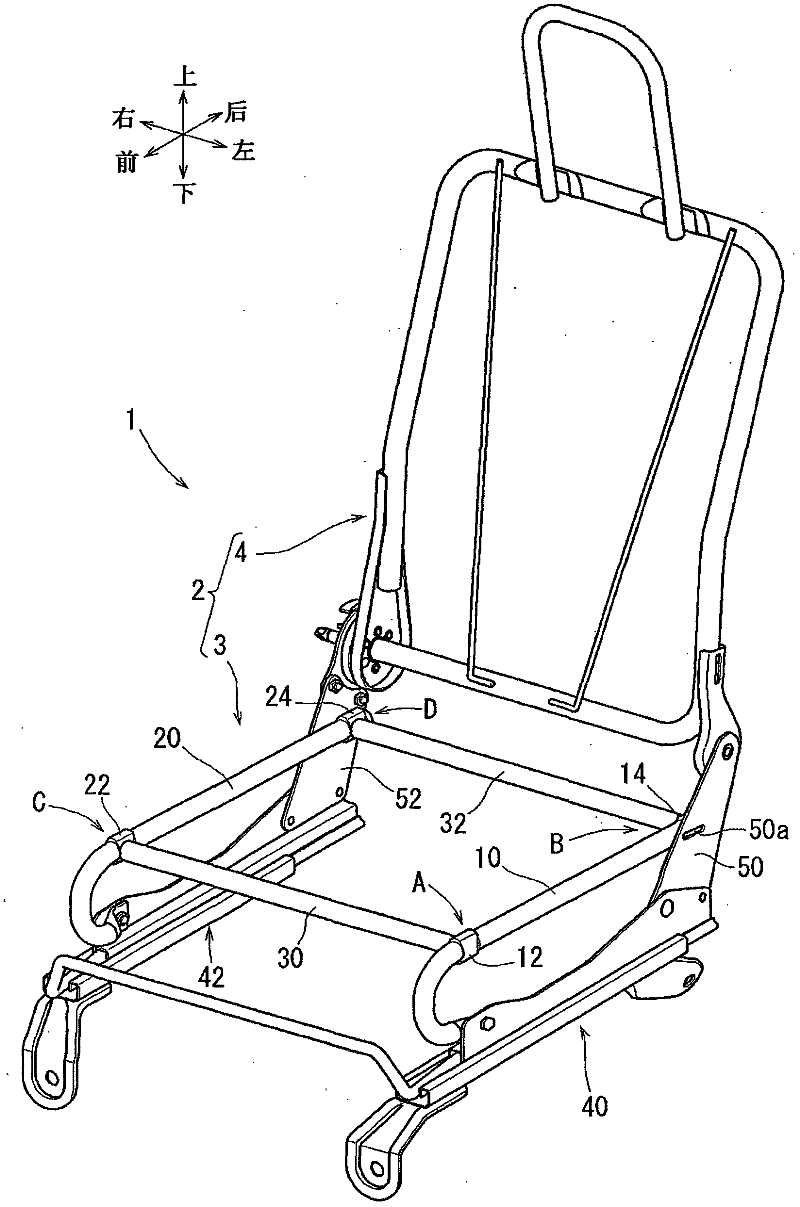

[0050] like Figure 5 As shown, the seat cushion frame 203 of the driver's seat 201 in this embodiment 3 is also composed of the left and right side frames 10, 20 and the front bar 30, The rear rod 32 is formed by butt welding and has a substantially rectangular frame shape.

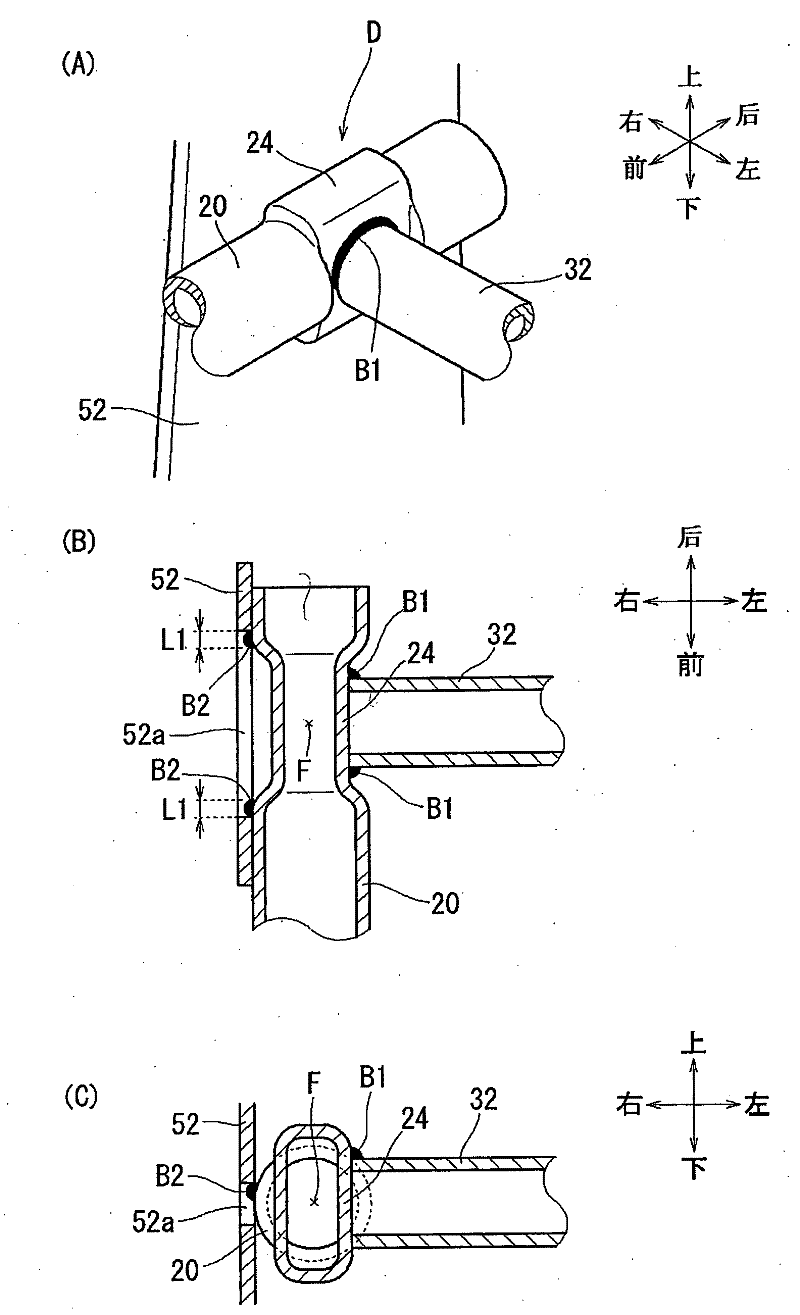

[0051] Here, the joining will be described in detail. In this third embodiment, the right rear part D among the four parts is described, and the description of the remaining three parts A, B, and C joined in the same manner as the right rear part D is omitted. In addition, for convenience of explanation, in the left and right side frames 10 and 20 , the places where the front bar 30 and the rear bar 32 are joined are referred to as joining parts 212 , 214 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com