Multi-mode steering hydraulic control system and wheeled crane using same

A steering hydraulic and control system technology, applied in the direction of fluid steering mechanism, etc., can solve the problems that the accuracy, sensitivity and reliability of the wheel angle are too dependent on precision and reliability, high cost, complex structure, etc., to achieve control of manufacturing costs, avoid The impact of faults and the effect of ensuring driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

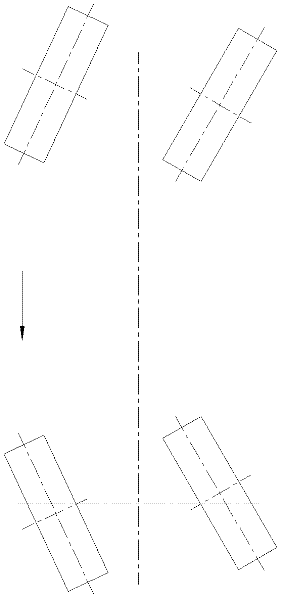

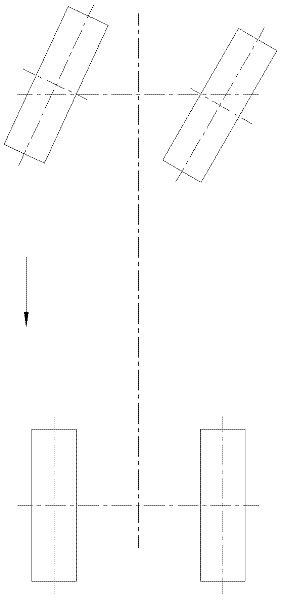

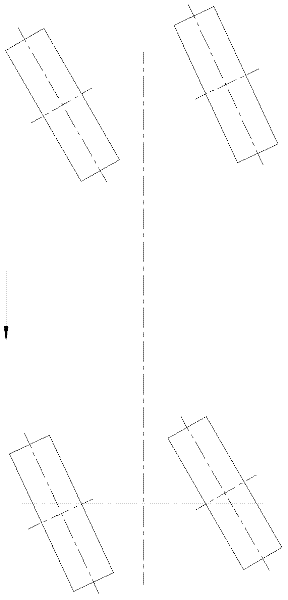

[0030] The core of the present invention is to provide a multi-mode steering hydraulic control system applied to wheeled construction machinery, which can ensure the safety and stability of related operations on the basis of meeting the basic operation requirements, and can effectively control the manufacturing cost of the whole machine. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0031] See Figure 4 , which shows the working principle diagram of the multi-mode steering hydraulic control system in this embodiment.

[0032]As shown in the figure, the multi-mode steering hydraulic control system uses the oil cylinder as the actuator of the steering operation to drive the front wheel 1 or the rear wheel 2 for adaptive rotation, so as to realize the steering function in different modes. In this embodiment, the front axle steering oil cylinders are specifically the left front steering oil cylinder 31 and the right fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com