Plugged box with distribution automation

A technology of power distribution automation and plug-in box, which is applied in the direction of electrical components, substation/switch layout details, etc., can solve the problems of poor overall rigidity, inability to install the motherboard quickly and conveniently, and inconvenient installation and use, so as to achieve structural transformation and plug-in , Easy replacement and assembly, simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

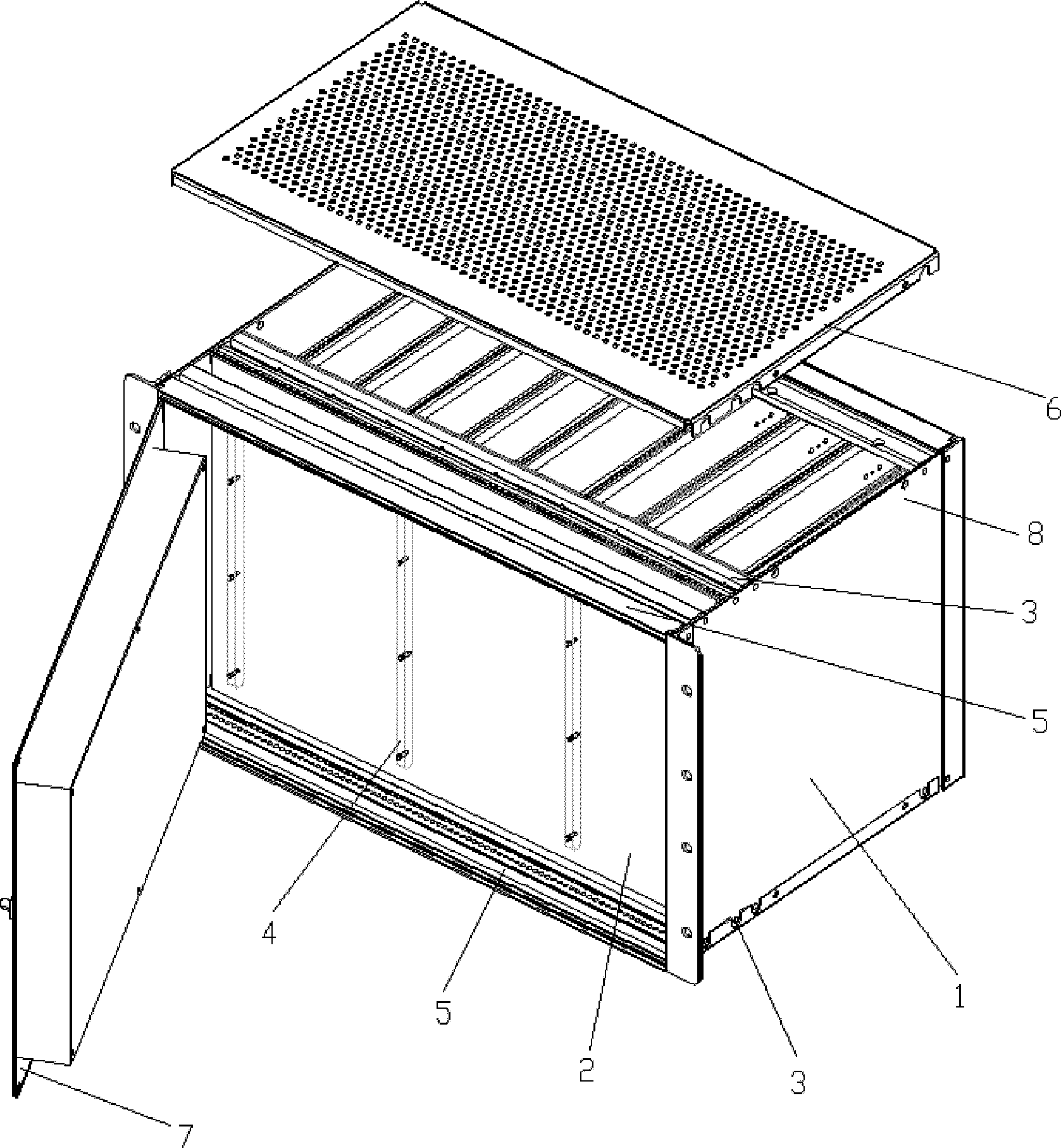

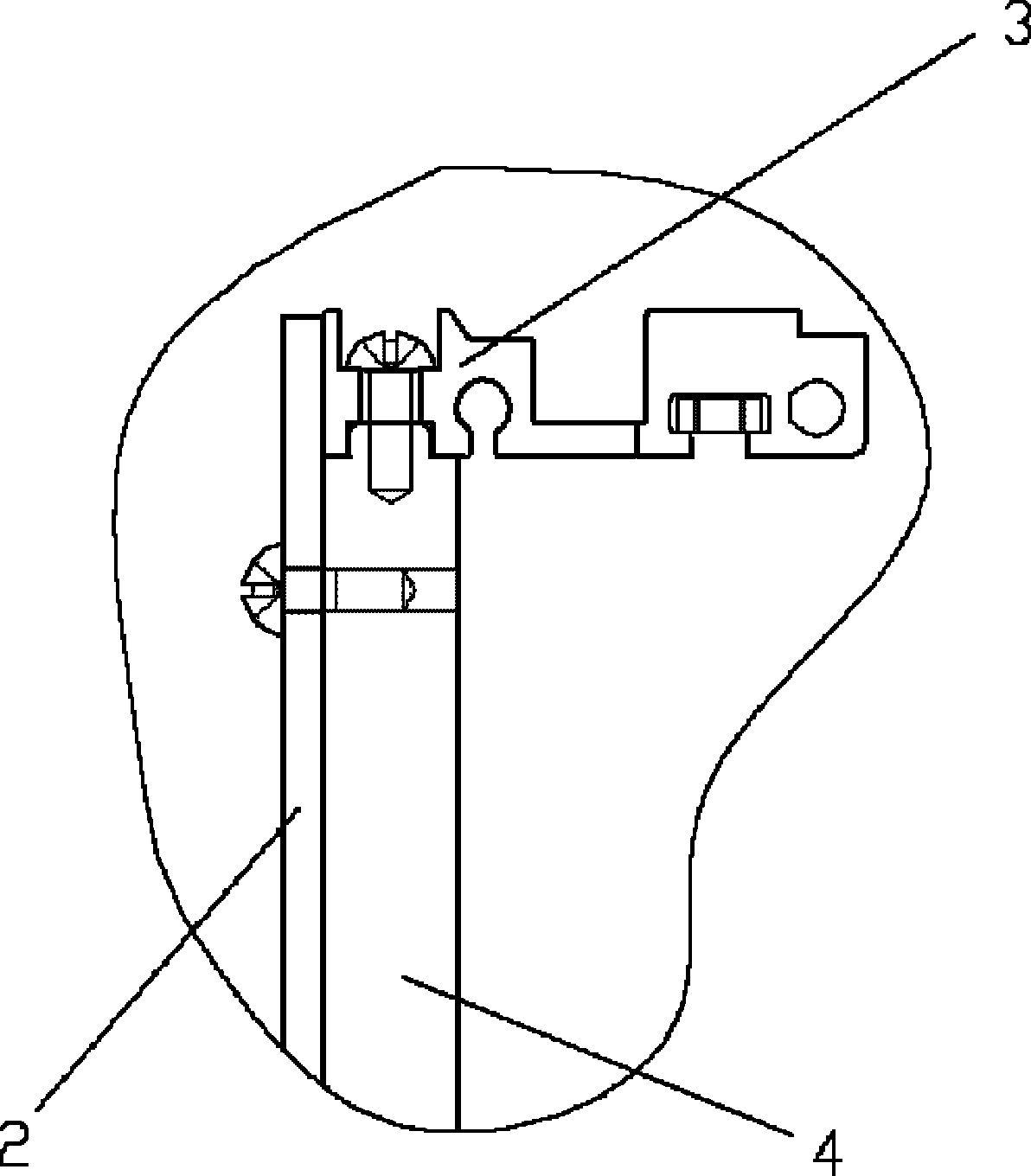

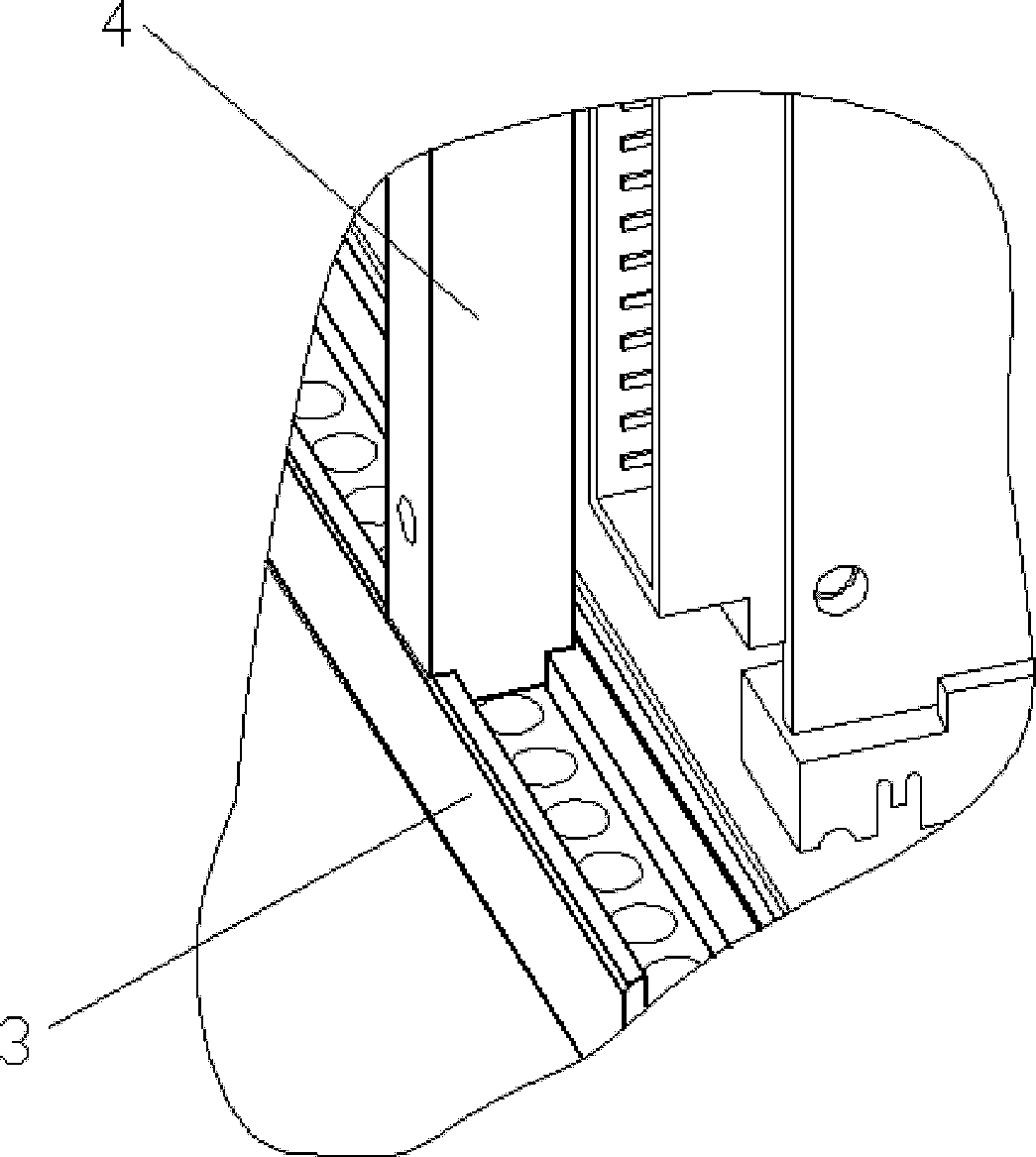

[0011] The main structure of this embodiment includes a box body 1, a motherboard 2 fixed in the box body, a cover plate 6 placed on the top of the box body, a middle beam 3 placed between side panels 8, and a front beam 5, which are connected with the upper and lower sides. The vertical beam 4 between the middle beams 3 is placed on the front panel 7 at the front of the box body 1; there is a certain opening distance between the front beam 5 in the box body and the middle beam 3, which is greater than the front and back depth of the motherboard 2, The opening distance is located under the cover plate 6; the opening distance of the box body 1 is distributed on the top and bottom of the box body; the motherboard 2 enters the box body 1 through the opening, clings to the corresponding vertical beam 4, and is fixed to the vertical beam 4 by screws On the middle crossbeam 3, there is an inverted groove, which is distributed on the upper and lower parts of the middle crossbeam 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com