Totally-enclosed main motor for vehicle

A main motor, fully closed technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problem of motor size limitation, and achieve the effect of ensuring cooling performance and reducing length and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

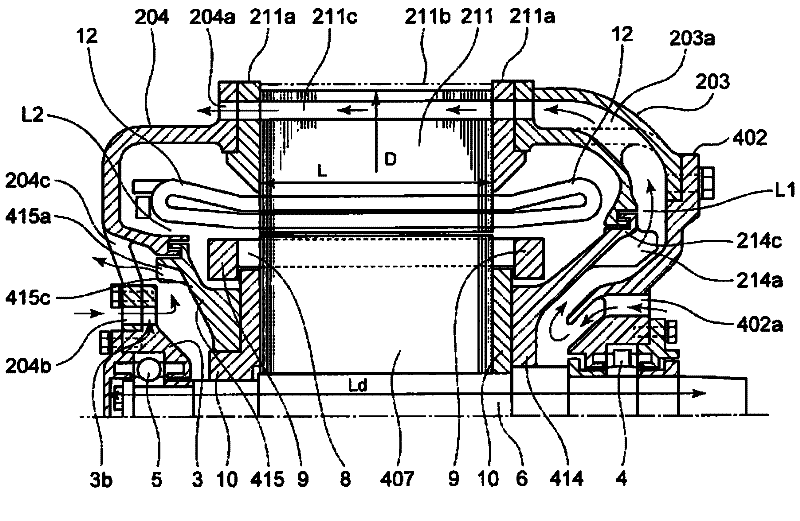

[0048] figure 1 It is a cross-sectional view of a fully enclosed main motor for a vehicle according to Embodiment 1 of the present invention.

[0049] On both sides of the stator core 211, core holding plates 211a, 211a are attached. A plurality of connection plates 211b are attached to a part of the entire outer circumference of the stator core 211 between the core holding plates 211a on both sides. A plurality of ventilation passages 211c are formed on the outer peripheral side of the stator core 211 by combining the plurality of connection plates 211b. A rotor core 407 and a ventilation fan 414 are attached to the rotor shaft 6 . The plurality of blades 214a are attached and arranged radially from the rotation axis at appropriate intervals in the circumferential direction of one surface of the fan main plate 214c of the ventilation fan 414 . The inner side of the fan main plate 214c extends to the vicinity of the inner peripheral side of the end ring 9 and is in close c...

Embodiment 2

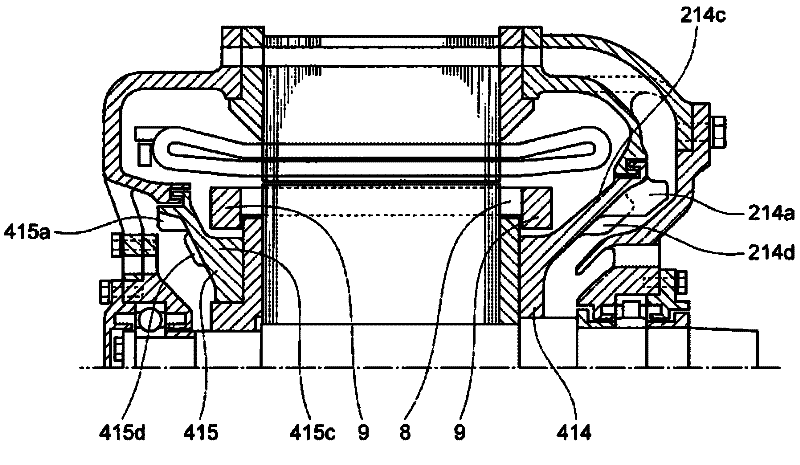

[0059] figure 2 It is a cross-sectional view of a fully enclosed main motor for a vehicle according to Embodiment 2 of the present invention. The Example 2 with figure 1 The difference of the illustrated embodiment 1 is that a cooling plate 214d is provided on the blade 214a side of the fan main board 214c of the ventilation fan 414, and a cooling plate 415d is provided on the blade 415a side of the fan main board 415c of the ventilation fan 415. The heat of the rotor (rotor bar 8, end ring 9) can be more effectively diffused to the outside by adding the heat sink 214a. A plurality of cooling plates 214d may be provided between adjacent blades 214a, or a cooling plate 214d may be provided or no cooling plate 214d may be provided between adjacent blades 214a. That is, the number, shape, and position of the heat sink 214d are not limited. In addition, a heat dissipation plate 415d is also provided on the outside of the ventilation fan 415, and its effect is basically the sa...

Embodiment 3

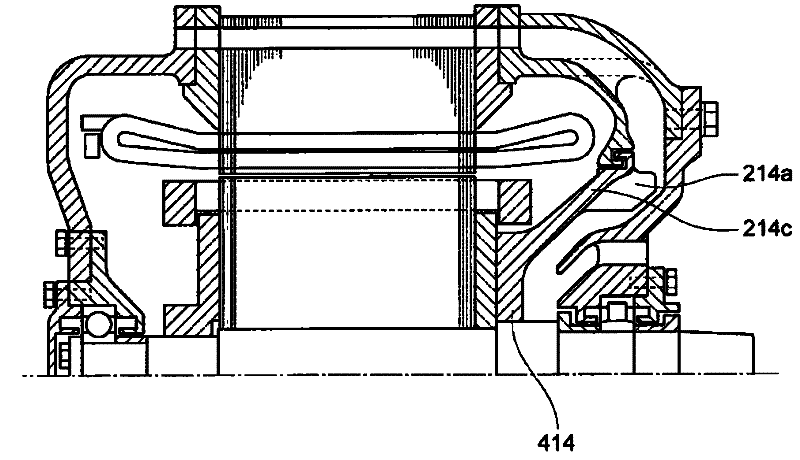

[0061] image 3 It is a cross-sectional view of a fully enclosed main motor for a vehicle according to Embodiment 3 of the present invention. The Example 3 with figure 1 The first exemplary embodiment shown differs in that the ventilation fan 415 on the side of the counter drive shaft is omitted. If sufficient cooling is achieved only by the ventilation fan 414 on the drive shaft side, there is no need to provide a ventilation fan on the counter drive shaft side. Furthermore, as shown in Embodiment 2, a cooling plate 214d may also be installed on the fan main board 214C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com