Cleaning roller with changeable bristles for belt conveyor

A technology for belt conveyors and cleaning rollers, applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems of accelerated conveyor belt damage, scratched conveyor belts, glue opening, etc., to prolong the service life and cleaning force Stable, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

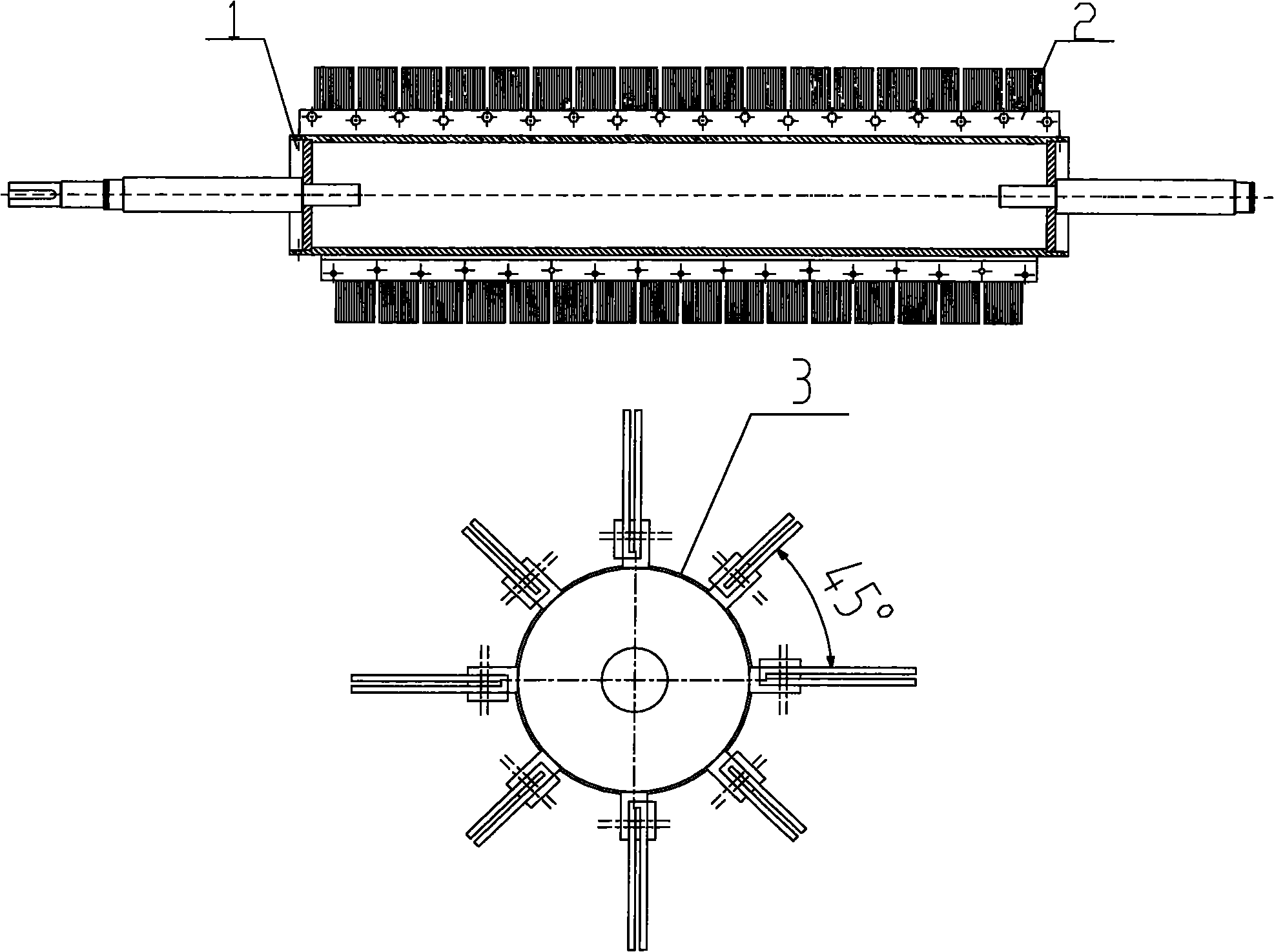

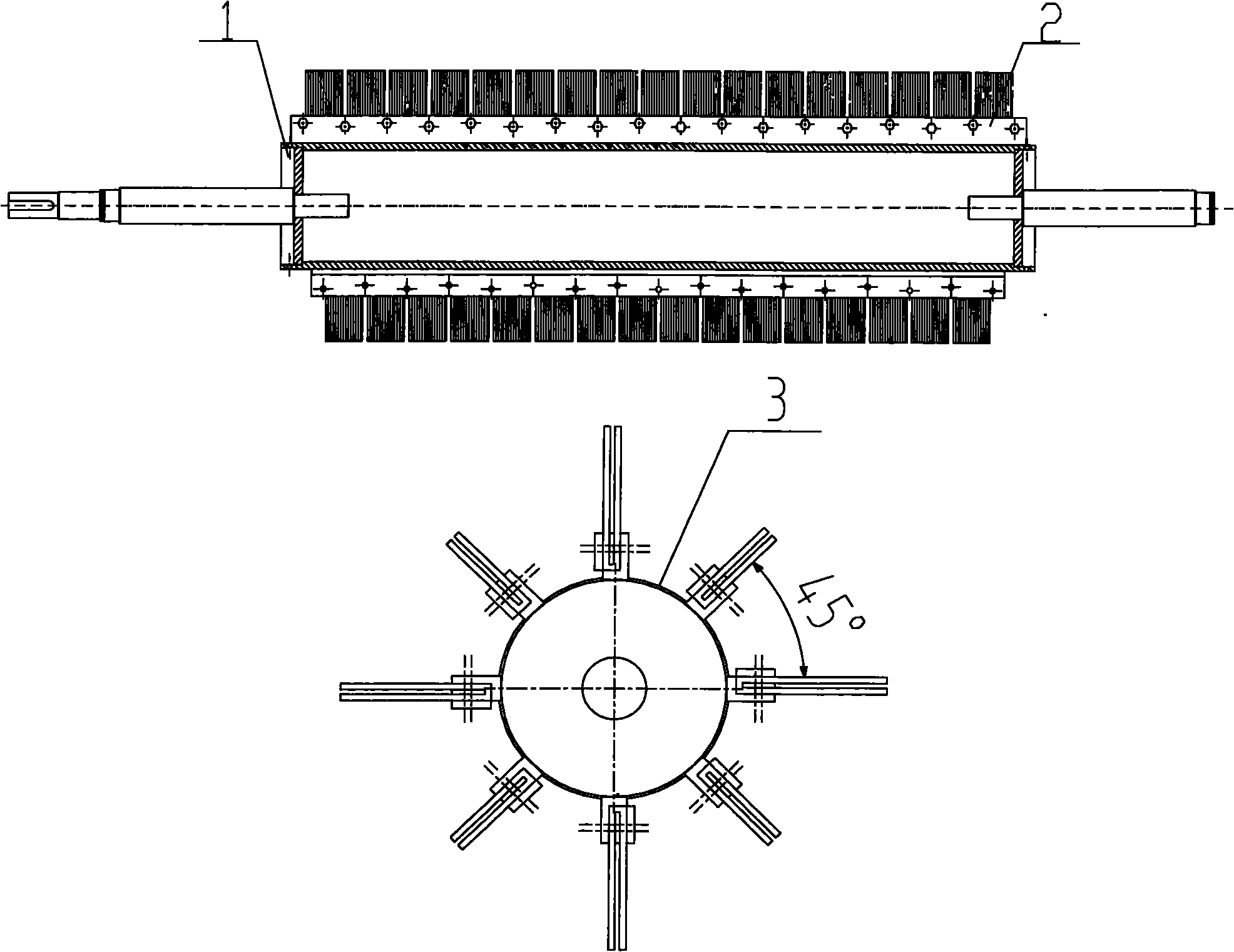

[0019] The belt conveyor of the present invention can replace the bristle cleaning roller, and its preferred embodiment is as follows: figure 1 , figure 2 As shown, the replaceable bristle cleaning roller for a belt conveyor includes an idler roller 1, a forming brush group 2 and a dustproof pad 3.

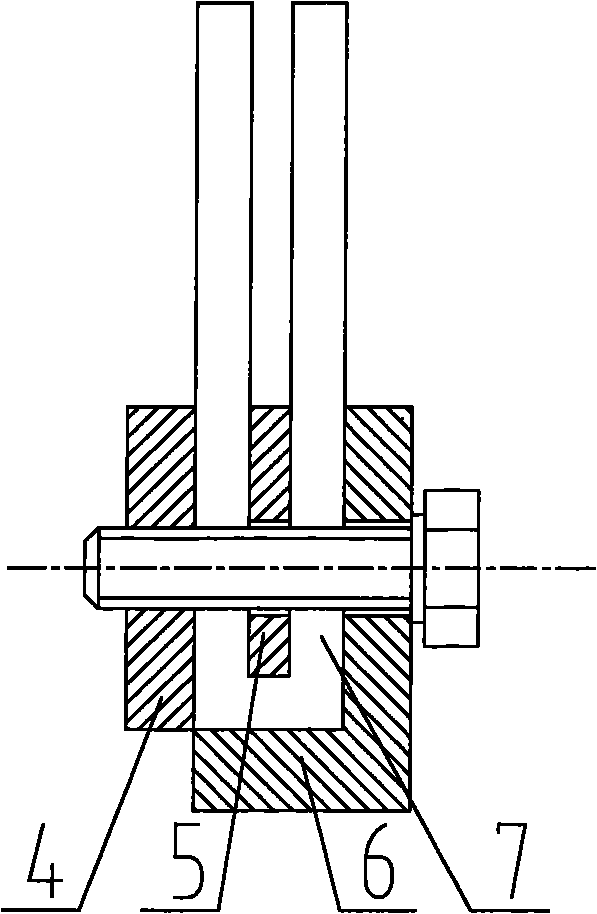

[0020] Forming brush group 2 is provided with fixed seat and bristle 7, and fixed seat is provided with pressing plate 4, forming plate 5 and L seat plate 6, and bristle 7 is " U " font and is located in the fixed seat.

[0021] The forming brush group 2 is arranged on the outer surface of the idler roller at an interval of 45°, and the forming brush set 2 is welded on the outer rotating surface of the idler roller. The bristles of the forming brush group 2 are 4 long and 4 short, a total of 8 lines, and each adjacent 2 lines One long bristle and one short bristle are arranged in a staggered manner.

[0022] The dustproof pad 3 is arranged on the outer rotating surface of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com