Needle plate of computer flat knitting machine

A computerized flat knitting machine and needle plate technology, which is used in knitting, weft knitting, textile and paper making, etc., can solve the problems of unstable fabric quality and large changes in the position of the needle plate before and after, so as to achieve small changes in the relative position of the front and rear, and improve the fabric quality. The effect of improving quality and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

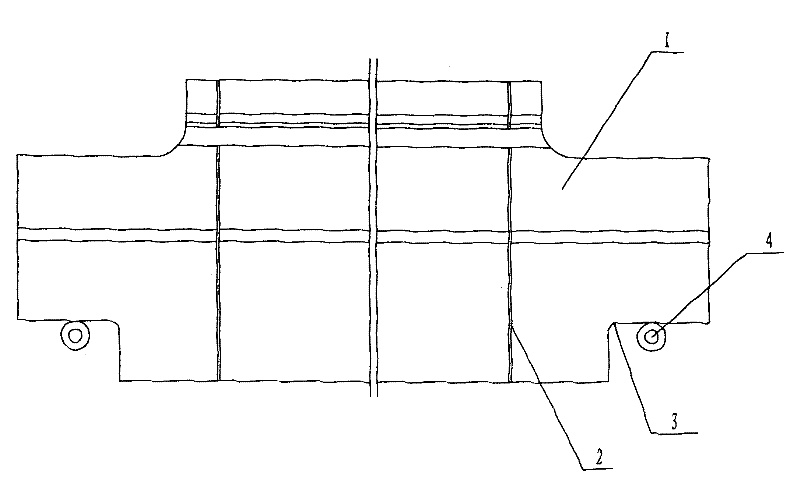

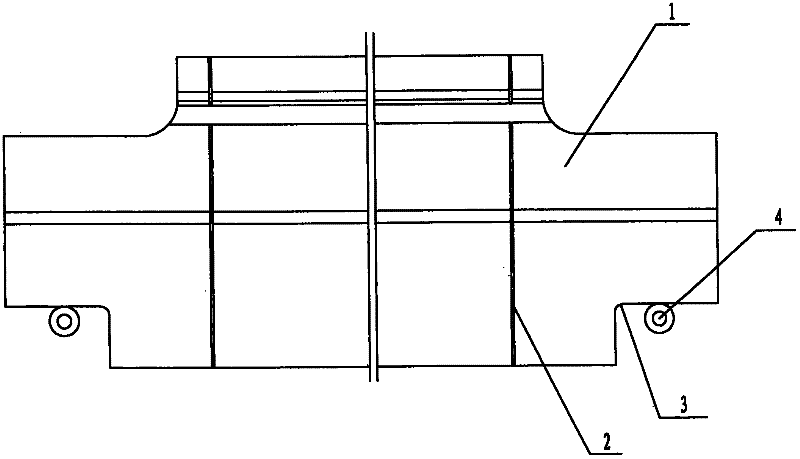

[0008] Such as figure 1 As shown, the present invention provides a needle board for a computerized flat knitting machine, a needle board for a computerized flat knitting machine, which mainly includes a needle board 1 on which pins 2 are arranged, and the needle board 1 is connected to a shaker, The rear portion of the needle plate 1 is symmetrically provided with two openings 3, and each opening 3 is provided with a bearing 4, so that the contact of the needle plate 1 changes from surface contact to line contact, and when the needle plate 1 moves left and right, the needle plate 1 Between the rear part and the support is changed from sliding to rolling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com