Automatic assembling machine of X framework of keyboard

A technology of automatic assembly machine and scissor foot, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of consuming a lot of time, energy and manpower, and achieve the effect of reducing the waste of manpower and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

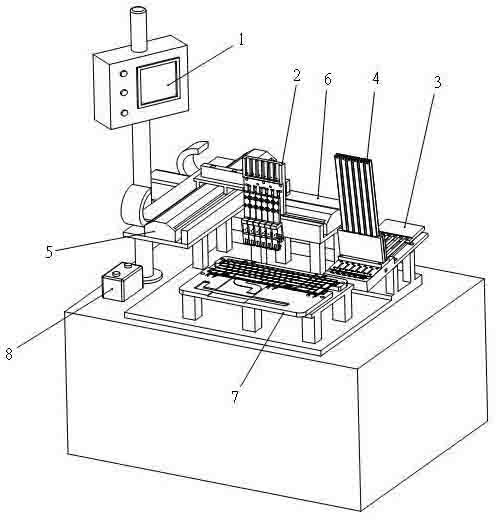

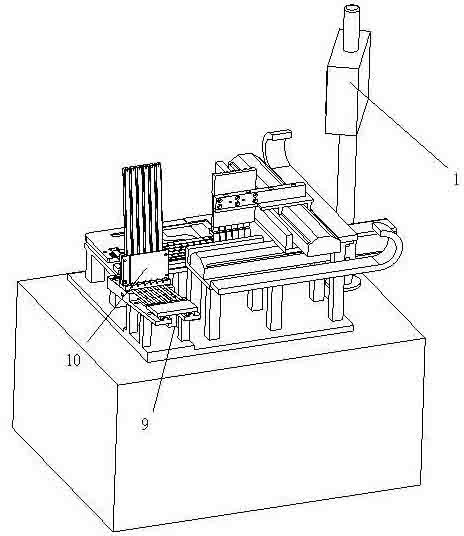

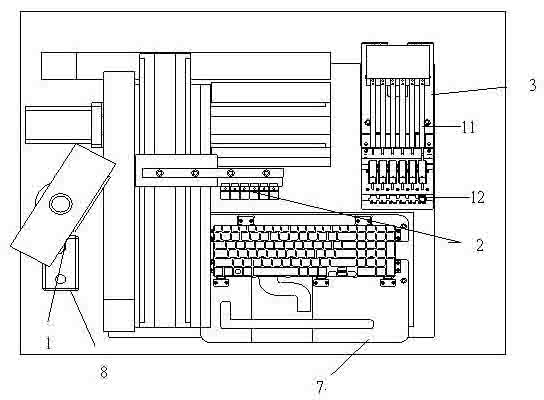

[0015] see Figure 1-3 , the invention discloses a keyboard scissors automatic assembly machine. As shown in the picture: it includes a machine, and the size of the machine is 1700mm*1000mm*1700mm. This machine table has a material pipe frame 1, and the material pipe 4 is inserted on the material pipe frame 1, and the position below the material pipe frame 1 is respectively corresponding to the material distribution track 11 of each material tube 4, and the front end of the material distribution track 11 is Scissor foot placement slots 12 are respectively provided. Figure 1-3 It is an embodiment of the present invention, and its material pipe 4, material distribution track 11 and scissor foot placement groove 12 are all correspondingly provided with by 6. The rear end of the material distribution track 11 is provided with a material pushing seat 3 driven by a cylinder 9; there is a material retrieving module 2 connected to the X-axis 5 and the Y-axis 6 near the tube frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com