Method and device for controlling a vacuum apparatus

A negative pressure device and negative pressure technology, applied in the direction of pump control, mechanical equipment, pump/compressor arrangement, etc., can solve problems such as failure of negative pressure supply, and achieve simple design, best effect and strong effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

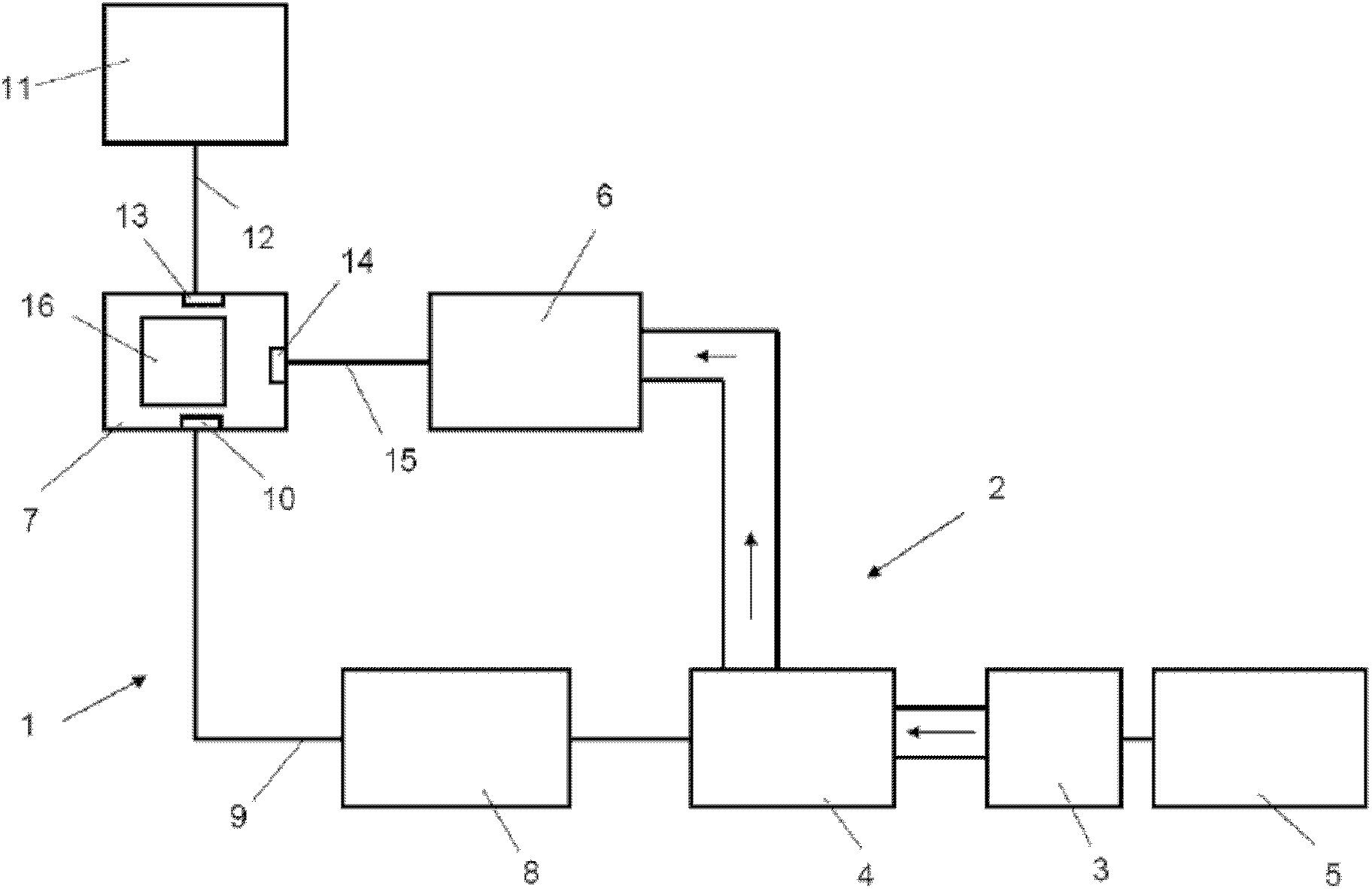

[0034] figure 1 A device 1 for controlling a vacuum device 2 of a pneumatic servo unit such as, for example, a vacuum brake booster 3 of a motor vehicle is shown. The vacuum device 2 has a vacuum accumulator 4 which is fluidically connected to a brake booster 3 which is activated by a brake pedal 5 . The negative pressure accumulator 4 is also fluidly connected to the intake manifold (not shown) of the motor vehicle engine. A line branches off from this connecting line to a pump 6, for example an electric suction pump. Usually a check valve is provided in the above connection line and only allows flow from said negative pressure accumulator 4 to said intake line. The pump 6 can apply negative pressure to the negative pressure accumulator 4 .

[0035] Airflow and its direction are indicated by arrows in the fluid lines. The negative pressure device 2 includes the negative pressure accumulator 4, the pump 6 and the fluid pipeline.

[0036] A controller 7 , such as for examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com