Manufacture method for resin seal molding product and manufacture apparatus for resin seal molding product

A technology of resin sealing and manufacturing method, which is applied in the fields of manufacturing resin sealing molded products and manufacturing apparatuses of resin sealing molded products, and can solve problems such as deformation and damage of connectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

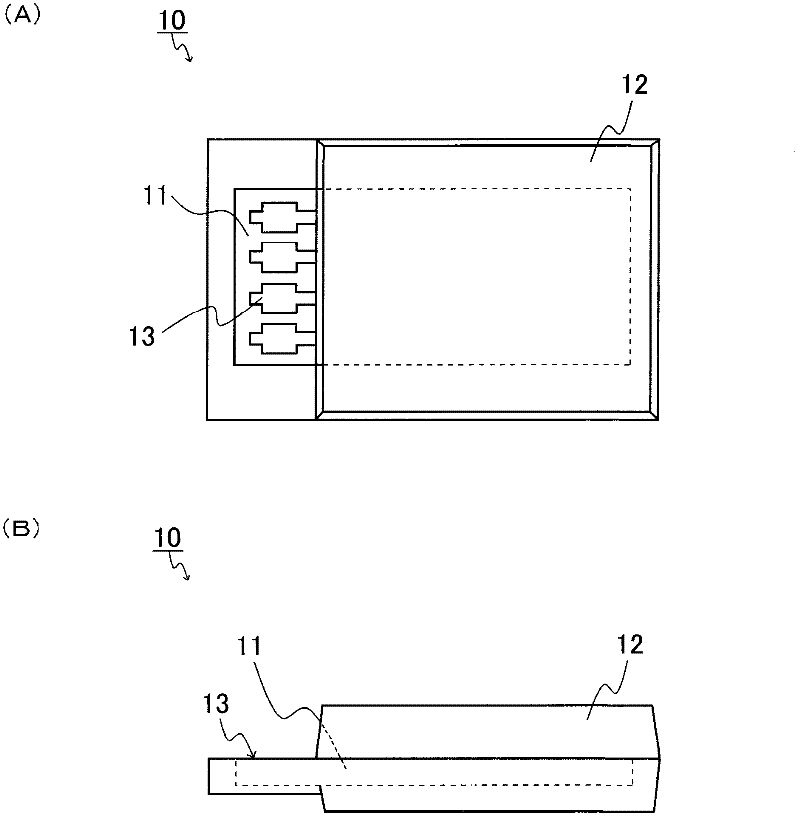

[0064] figure 1 It is a figure which schematically illustrates the resin-sealed molded product which can be manufactured using the resin-sealed molded product manufacturing apparatus or the resin-sealed molded product manufacturing method of this invention. figure 1 (A) is a plan view (above), figure 1 (B) is a side view. As shown in the figure, the resin-sealed molded product 10 is a resin-sealed molded product in which the outer surface of a substrate 11 on which electronic components are mounted is sealed and molded with a resin-sealed molded body 12 in which a resin material is cured. In addition, the pre-resin-sealed substrate 11 of the resin-sealed molded product 10 has an exposed substrate-exposing surface 13 . It does not specifically limit as the resin-sealed molded product 10, For example, a vehicle-mounted part is mentioned. The substrate exposed surface 13 preferably has, for example, good electrical contact and no sealing resin adheres thereto.

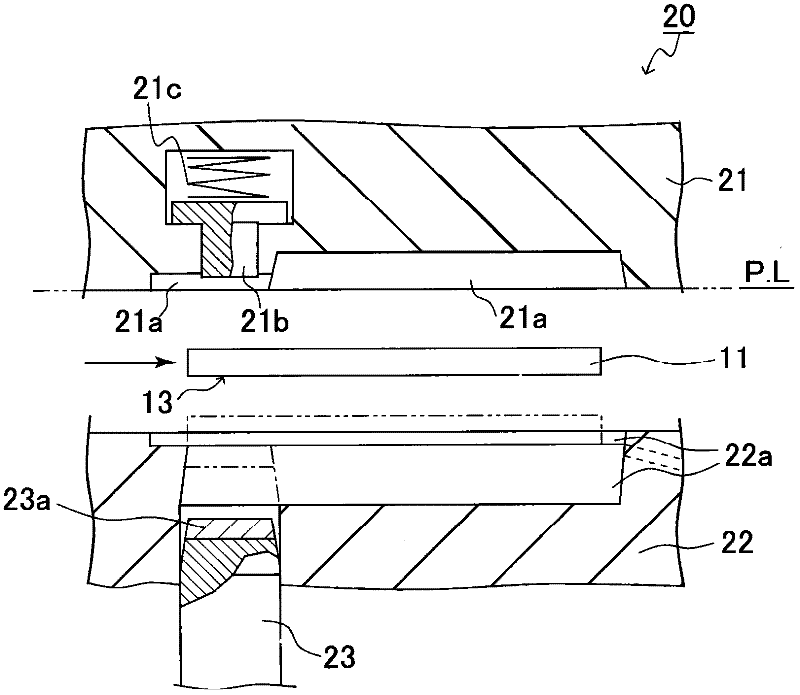

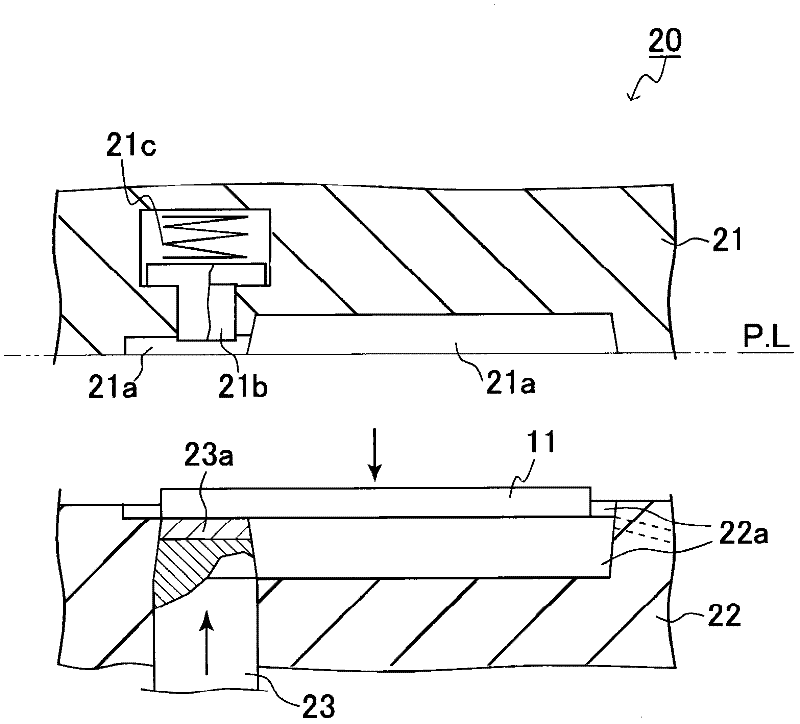

[0065] f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com