Manufacturing method of micro-structure optical plate with high transferring rate

A manufacturing method and microstructure technology, which can be applied to optical components, household appliances, other household appliances, etc., can solve the problems of unsuitable optical boards, affecting optical properties, and insufficient transfer rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

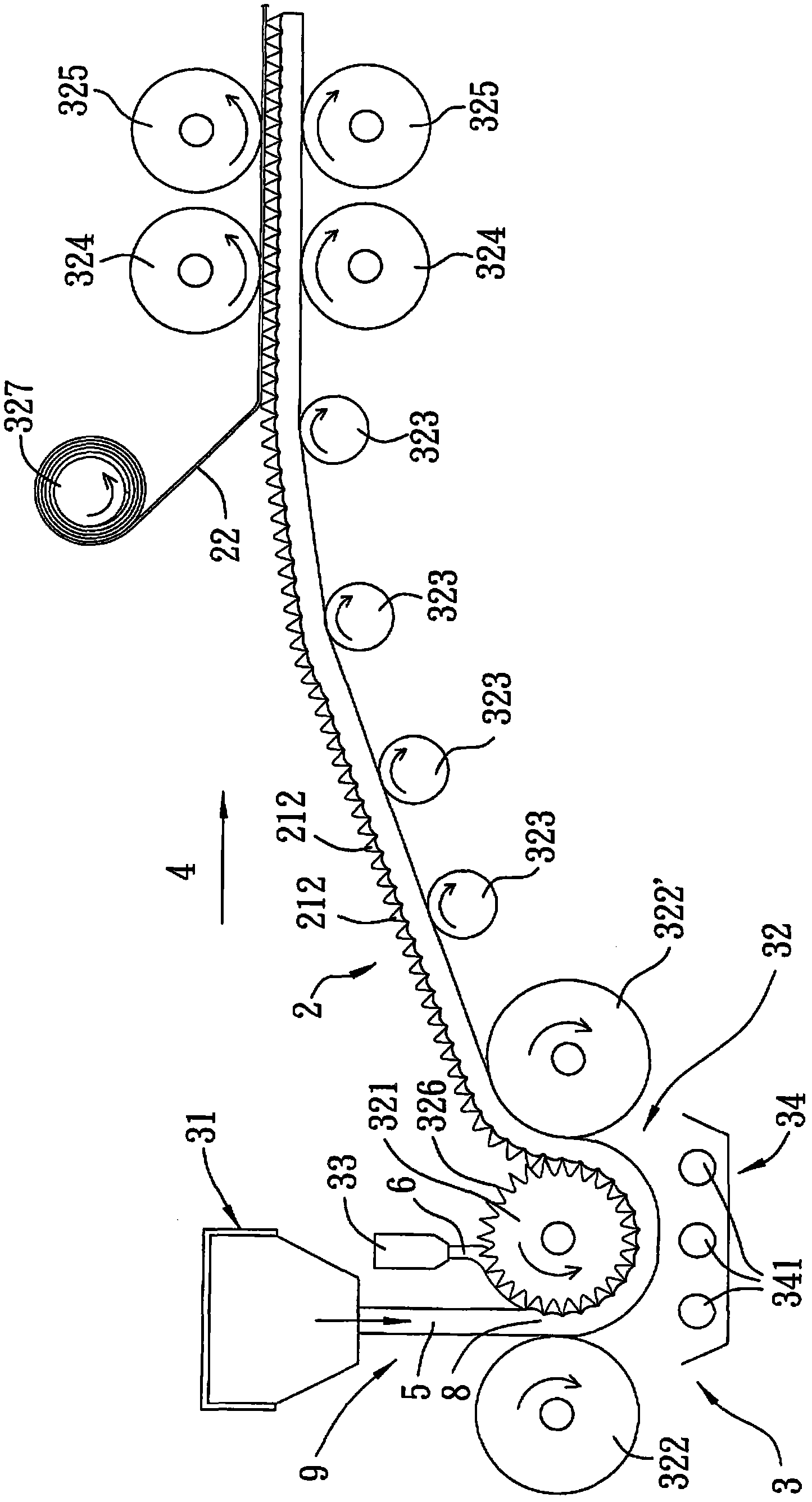

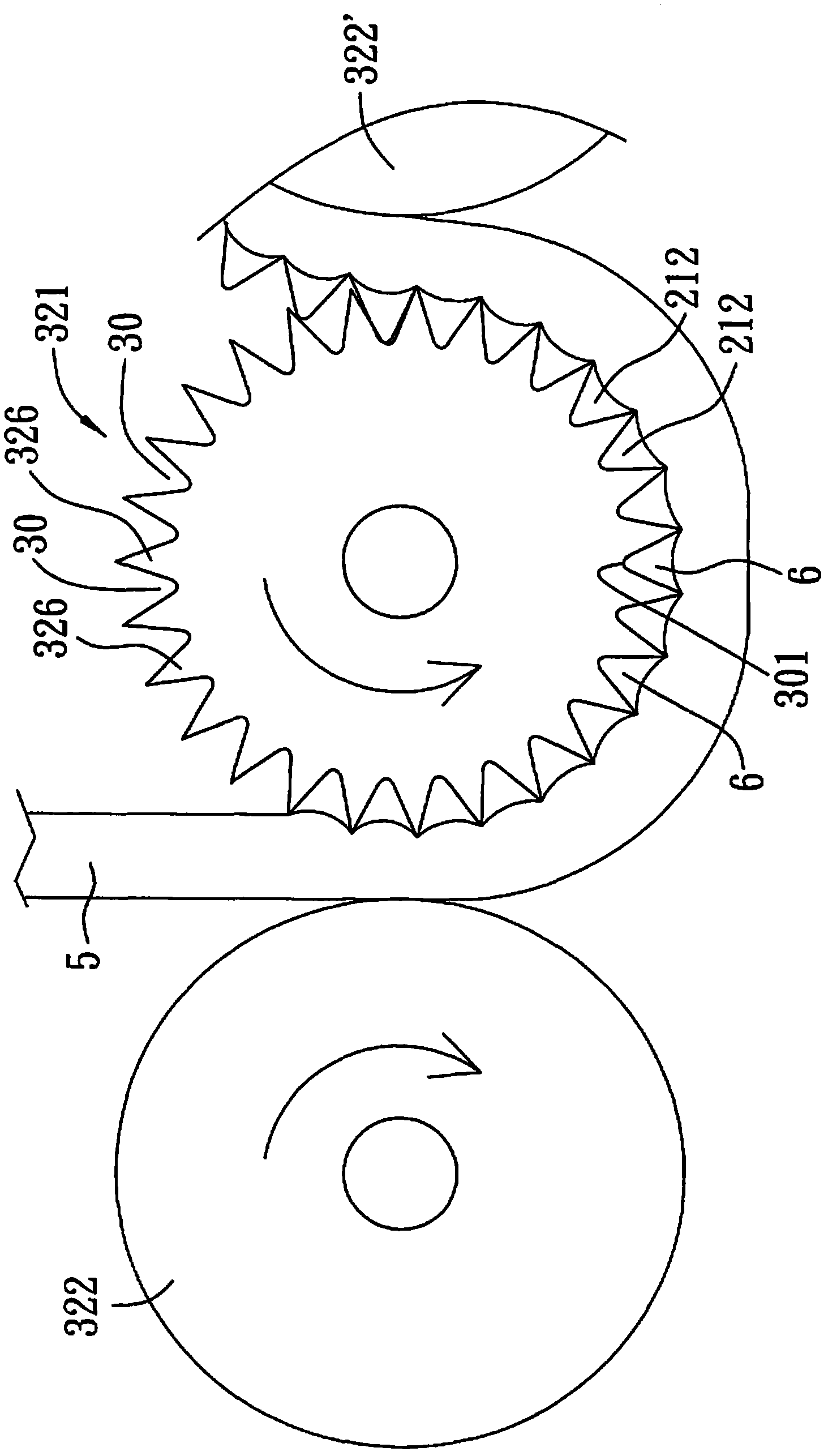

[0048] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

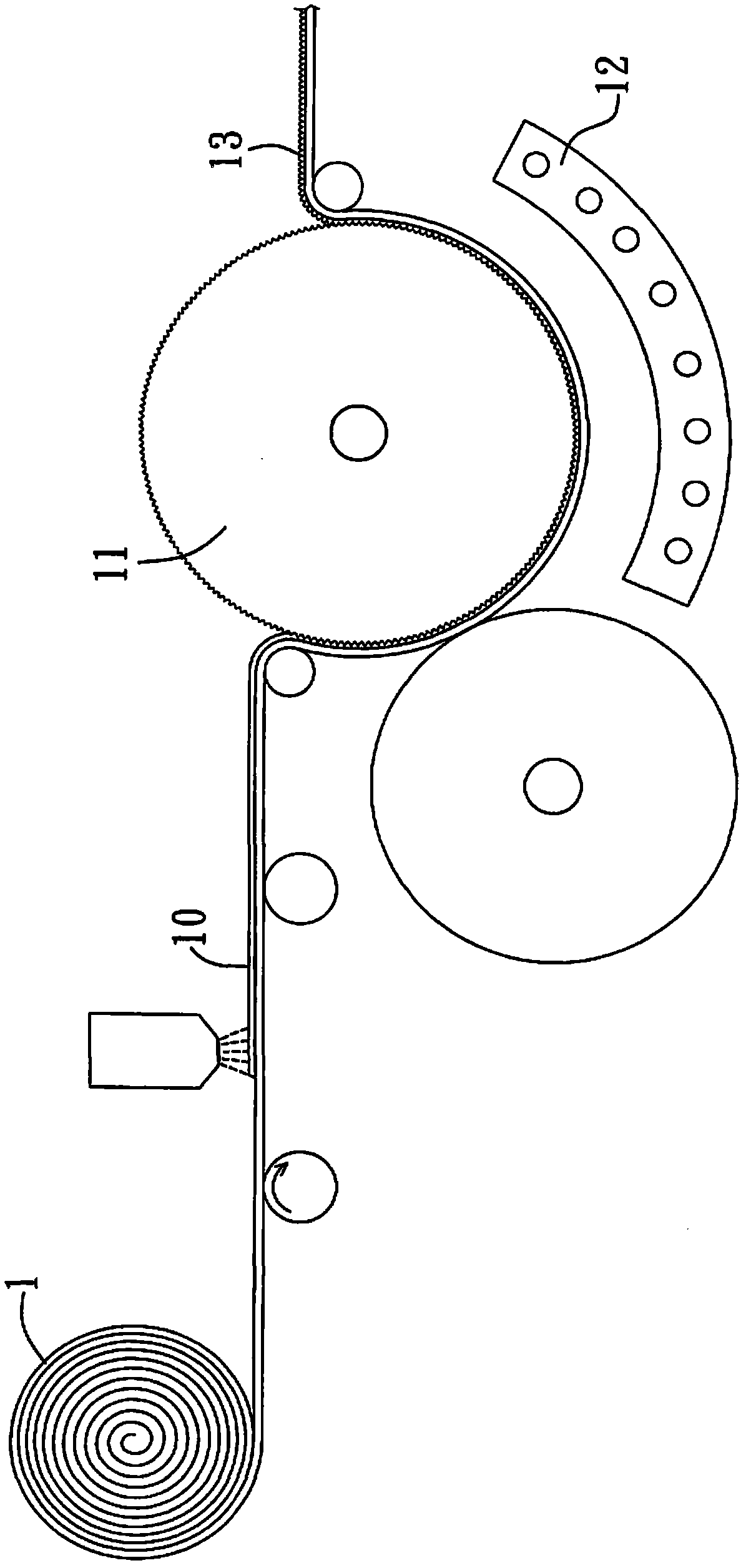

[0049] refer to figure 2 , 3 , 4. A preferred embodiment of the manufacturing method of the present invention is to manufacture a piece of microstructured optical plate 2 through a molding device 3. In this embodiment, the microstructured optical plate 2 is a light diffusion plate, and the molding device 3 includes: a die head 31, a roller unit 32, a photosensitive resin material filling bottle 33, and a set of lighting equipment 34. Wherein, the roller unit 32 includes a transfer roller 321, two pressing rollers 322, 322', multiple adjacent conveying rollers 323, multiple film sticking rollers 324, multiple pulling rollers 325, and a Between the conveying roller 323 at the end and the film sticking roller 324 is a rolling roller 327 for a piece of protective film 22 to be wound. Here define a production line from upstream to downstream for direction 4, in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com