Winding method and winding device for venetian blinds or honeycomb blinds

A wire winding device and honeycomb curtain technology, which is applied in the field of door curtains, can solve the problems of loss of manufacturers and customers, failure to make louvers, fluffing of flat belts, etc., and achieve the effects of good balance of louvers lifting, beautiful products, and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the present invention is further described by taking an electric sunshade hollow glass inner shutter / door as an example, but the present invention is not limited to this specific example.

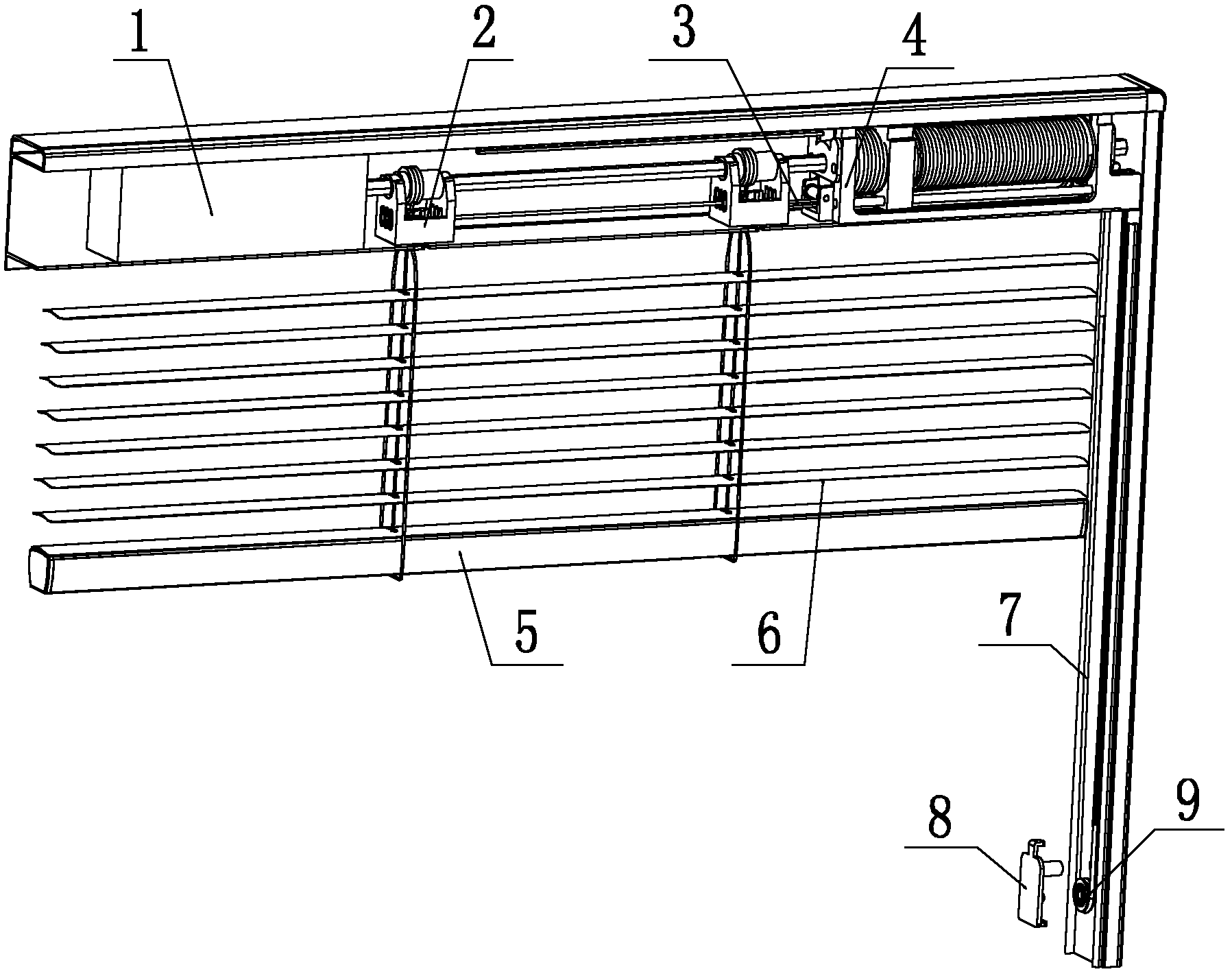

[0027] Such as figure 1 As shown, the present invention includes a driving source 1 (such as a motor), a dimmer wheel assembly 2, a multi-strand lift cord 3, a reel assembly 4, a lower beam 5, a venetian blind 6, and a traction cord 7.

[0028] The dimming wheel assembly 2 is located at the position corresponding to each lift cord above the louvers 6, and it includes a dimming wheel that drives the dimming stay cord to move and a steering device that makes the lift cord 3 move horizontally from up and down (such as steering wheel, not shown in the figure).

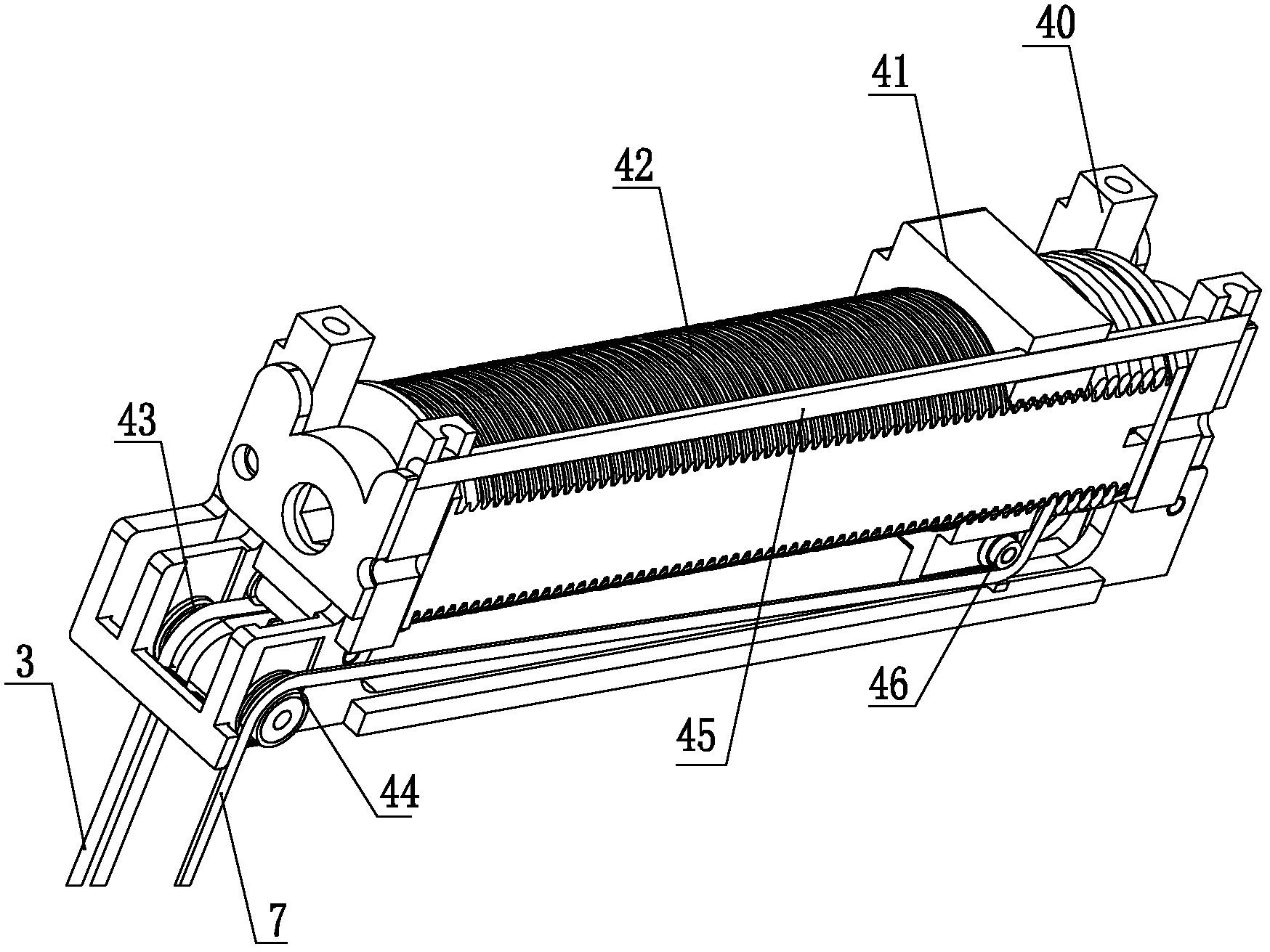

[0029] Such as figure 2 As shown, the reel assembly 4 is located on the side of the dimmer wheel assembly 2, and includes a reel seat 40, a threaded reel block 41, a screw reel 42, small reel wheels 43, 44,...

Embodiment 2

[0034] This embodiment is the same as Embodiment 1, and both include a driving source 1 (such as a motor), a dimmer wheel assembly 2, a multi-strand lift cord 3, a reel assembly 4, a lower beam 5, a venetian blind 6, and a traction cord 7. Turn to Ferry 9 and so on.

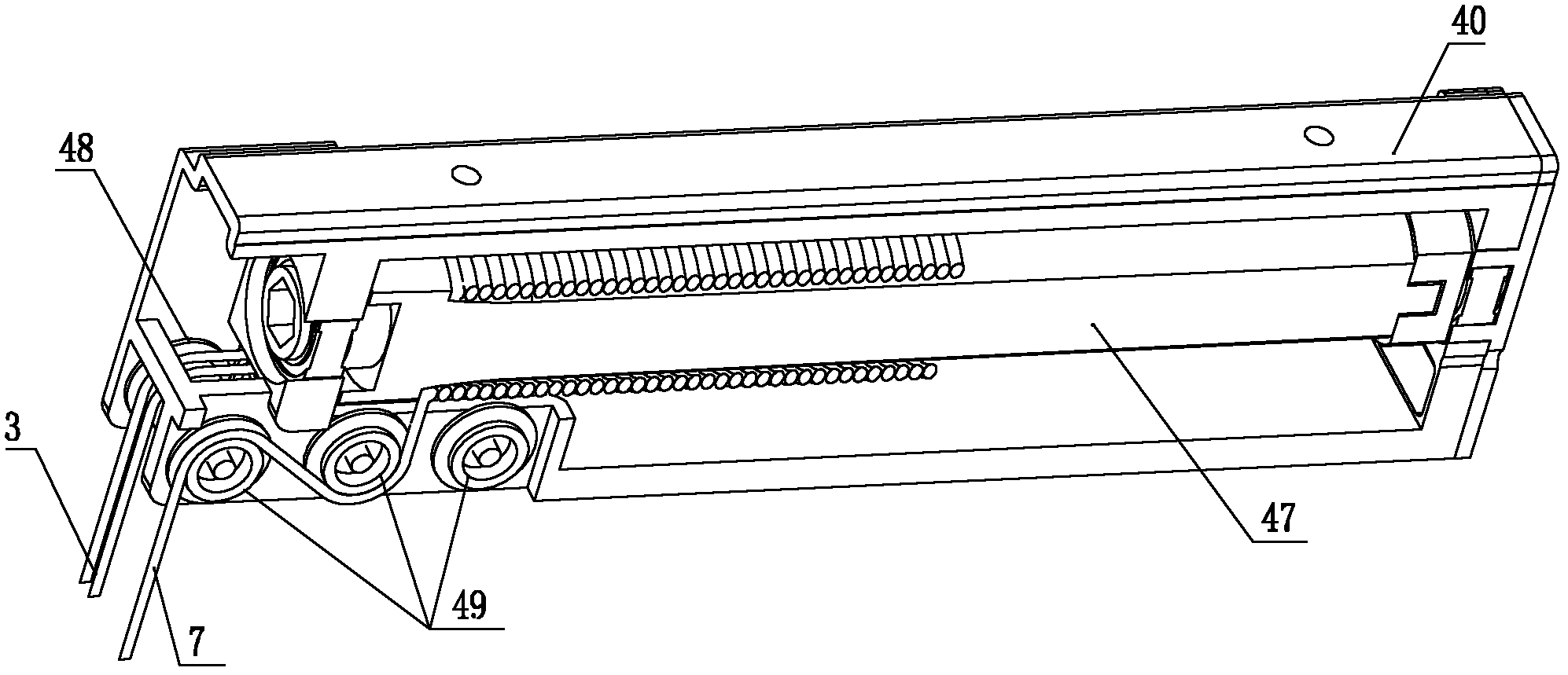

[0035] Such as image 3 As shown, the reel assembly 4 is located on the side of the dimmer wheel assembly 2, and includes a reel seat 40, the driving source 1 drives the screw reel 42 to perform circular motion, and at least two small reels. Tubular reel 47 is smooth in surface and has certain taper, and bearing is equipped with at both ends, is fixed on the reel seat 40. In this embodiment, four winding small wheels are arranged below the barrel-shaped reel 47 . Several strands of lifting stay ropes 3 extend downwards after passing one of the reels 48, and are tied up by another traction stay rope 7, and the traction stay ropes 7 extend upwards after bypassing the steering wheel 9, and pass through the other t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com